is special.

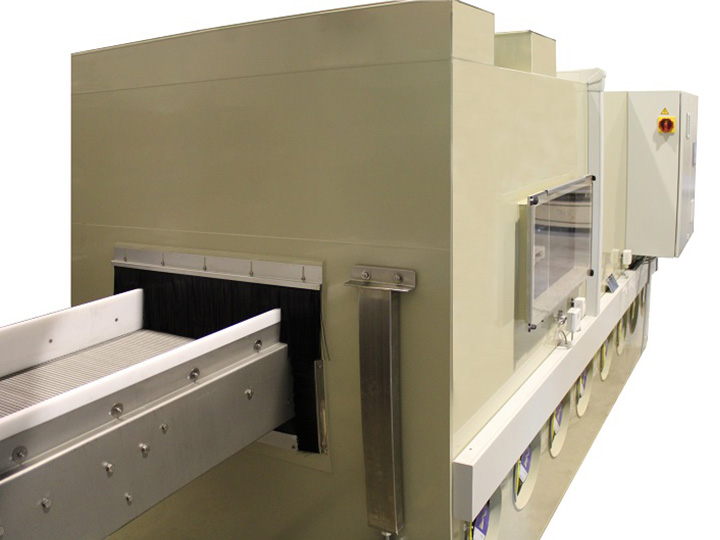

Drying in a

continuous Process

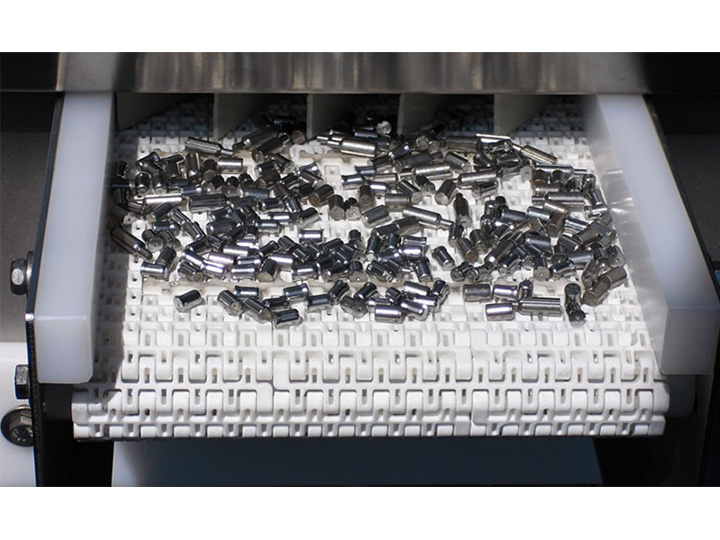

Continuous drying processes have their specific requirements and challenges. We modify our dehumidification module to meet the requirements of your product and throughput. For continuous drying within specified cycle time, the air routeing must be fine-tuned to suit the specific product. Even the driest air is of no avail unless directed to the spot where humidity is to be absorbed. And this is exactly what we successfully implement.

Retaining Energy in the System

Continuous drying on a belt or in a tunnel involves openings at the entrance and exit ends. Such openings must be considered when calculating the water absorption performance. We always try to minimize openings in the drying chamber to prevent undesired air loss and to keep the system as closed as possible.

Upstream Non-compressed Air Blowing Station

We offer optional non-compressed air blowoff before the drying process proper for particular applications. For details click here.

Drying and Cooling

Any continuous drying system may have a cooling zone integrated in order to obtain a product ready to be packaged.

Belt dryers, tunnel dryers and continuous dryers with or without cooling zone are special solutions which we will be happy to design for you. Just contact us!