is special.

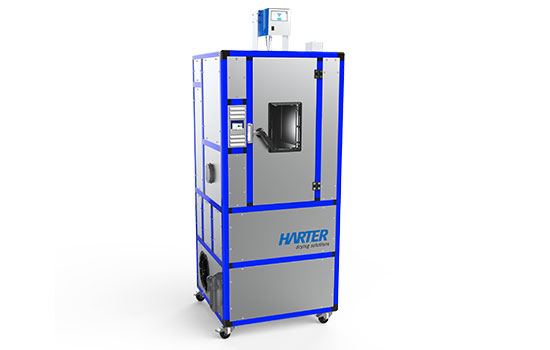

AIRGENEX®–Drying Technology –

for an absolutely perfect Result

With sufficient dry air and the right air flow, the smallest parts are dried completely, spotlessly and gently after electroplating, vibratory finishing or cleaning. Our condensation drying with heat pump in a closed air system enables energy-saving drying at low temperatures – with an absolutely perfect result. With this safe alternative, a process changeover from cleaning and drying with alcohol to aqueous cleaning with ultrasound and deionised water and subsequent optimal drying by Harter is also successful.

Drying in Vibarrel® Baskets

Bulk watch parts in baskets can be dried in so-called Vibarrel® baskets. Vibration causes movement in the baskets so that the parts always move in a circle. The bulk material is surface-coated and dried directly in the Vibarrel® baskets. Previous centrifuging or drying with alcohol are now a thing of the past. Harter dryers are equipped with a special airflow system that automatically adjusts to the size of the Vibarrel® baskets. In this way, different basket sizes can be run in one dryer to achieve maximum efficiency.

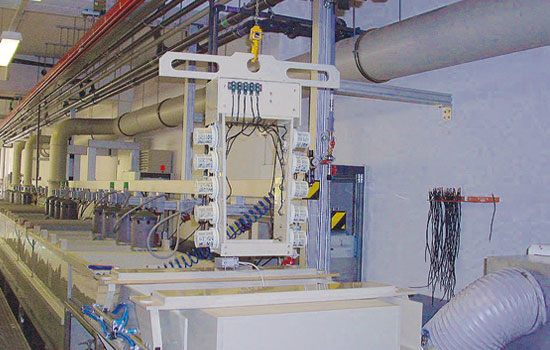

Drying of round Frames

Drying in Screen Baskets

Bulk materials in screen baskets are also dried completely and homogeneously within the required cycle time thanks to the ingenious combination of extremely dry air and the right air guidance. Our low temperature drying avoids any staining or overheating due to its physically alternative approach.