Dry Safely and save Energy

A manufacturer of safety components was looking for a new dryer that would meet the requirements posed by its broad parts portfolio. They opted for condensation drying based on heat pumps, in which the bulk material is dried directly in the drum.

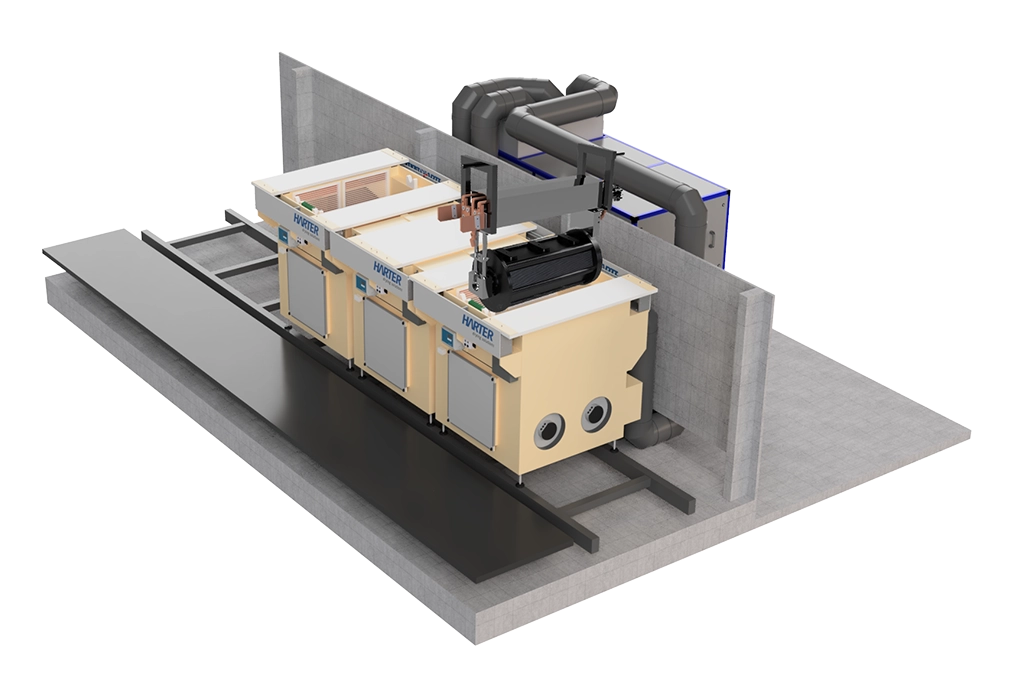

The condensation drying process based on heat pumps developed by the dryer manufacturer Harter proved to be a suitable solution for replacing the outdated dryer of a specialist for safety elements with state-of-the-art technology. The project began with drying tests in Harter’s in-house technical center. The parameters required for successful drying were determined: time, temperature, humidity, air volume flow, air velocity, and air guidance.

You can find the complete project report here.