Primary and secondary packaging made of plastic, glass, or metal, metal strips, plastic films, or thin liquid films on surfaces must be reliably dried after cleaning, pasteurization, or sterilization to allow for subsequent printing, labeling, final packaging, or further processing.

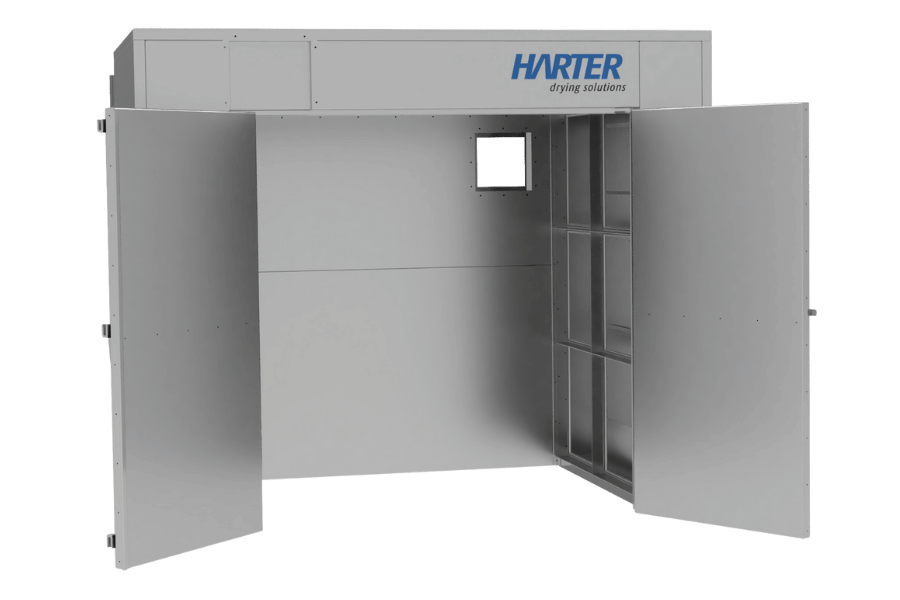

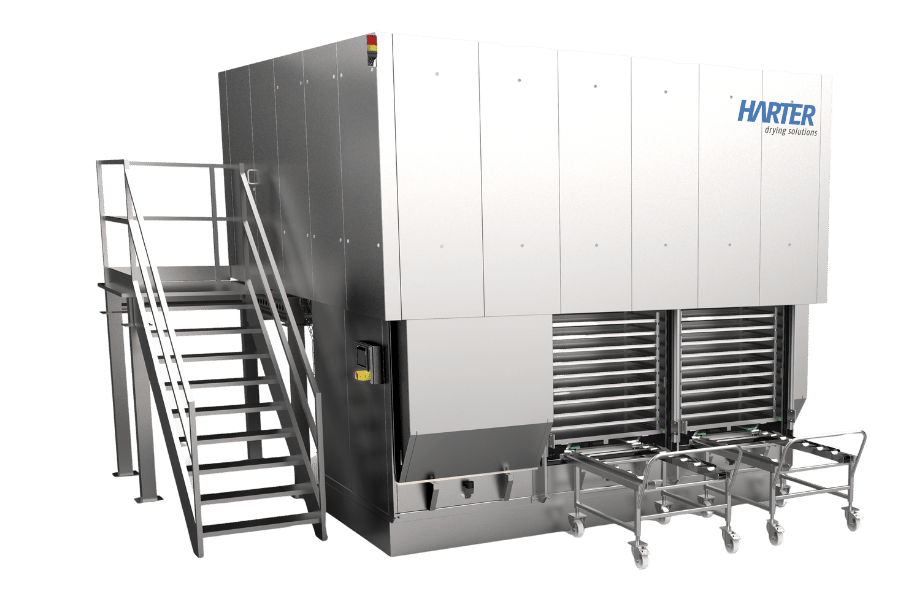

With the Airgenex® condensation drying developed by HARTER, packaging can be dried efficiently and in no time, whether in a continuous process or in batch operation.

Learn about our technology and its benefits for your product. Discover how our dryers work and how diverse their applications are.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Your benefits

Drying Systems for Packaging

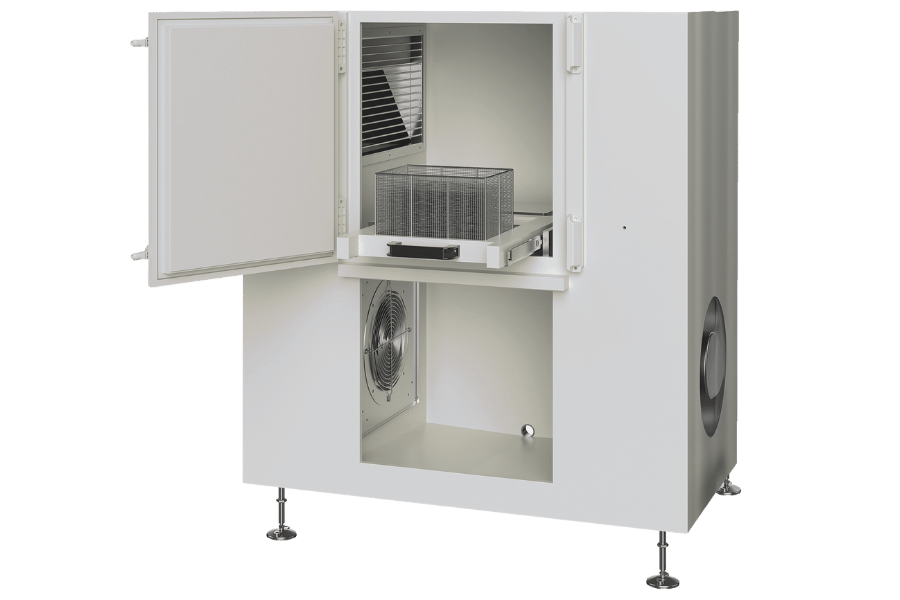

We develop and manufacture drying systems for both batch operation and continuous processes, thereby adapting our technology to your process and your product. We determine all specific parameters for successful drying beforehand in drying tests at our technical center.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.