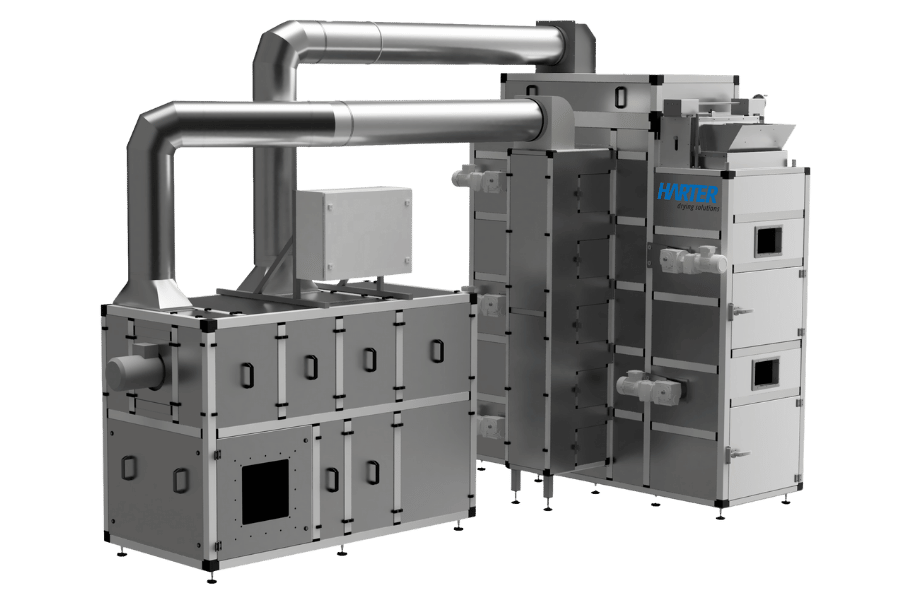

Modernization with heat pump and optimized air flow

HARTER retrofits existing drying systems with Airgenex® or Drymex® technology: heat pump-based condensation drying in a closed air circuit, precise air flow, and modern control technology. This allows you to increase quality and throughput, reduce energy and CO₂ costs, and remain independent of the indoor climate – with predictable downtime. This avoids the costs of a complete new purchase and significantly reduces conversion and downtime. A retrofit is particularly recommended for very large, mostly fully automated systems; for smaller applications, a complete new system from HARTER is often the more economical and process-reliable solution.

Do you have individual requirements that you would like us to test in advance?

From Idea to Custom Solution

Practical Tests in Our In-House Laboratory

For challenging applications, HARTER develops tailor-made custom solutions. In our technical center, we test your product under realistic conditions, define temperature and humidity windows, optimize cycle times, and document the results. Contact us – we will review your task without obligation and provide a clear recommendation for the next steps.

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Your benefits

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

Fill out the form now and we will get in touch with you as soon as possible.