Why HARTER?

“With our energy- and CO₂-saving heat pump technology, we contribute to energy management and climate protection, topics that have gained significant importance worldwide. Just a few years ago, energy savings when purchasing a dryer were a nice bonus. Today, they – and with them CO₂ savings – are a top priority and thus a reason for investment. Not least because government funding is often available for our integrated heat pump technology.”

Sincerely, Reinhold Specht

Managing Partner

HIGH-TECH - IN-HOUSE

Made in Germany

Offering you consulting, engineering, and all other services from a single source is part of our philosophy. In our specialized, development, and manufacturing departments, we achieve a very high level of vertical integration for all drying areas. Our After-Sales Service perfectly complements

our range of services.

Committed – Experienced – Reliable

Our strengths are ideas and experience.

In collaboration with you as our client, solution options

and variations for your individual drying requirements are developed.

Made in Germany

Everything from a single source: From consulting and engineering to all accompanying services – that is what we stand for. Our specialized, development, and manufacturing departments ensure an impressive level of vertical integration across all drying areas. With our After-Sales Service, you receive the perfect complement.

Our qualified and predominantly regional partners and suppliers provide us exclusively with first-class materials and high-quality services. We maintain long-standing and excellent business relationships with them. All of this forms the foundation for our successful work.

Technical Center

In our Technical Center, we can conduct tests with your products and determine the crucial parameters for successful drying – temperature, time, humidity, air velocity, and guidance. We document the efficiency of our drying technology for your application. Of course, you are also welcome to participate in the test series and see for yourself.

After-Sales Service

We place great importance on our drying systems achieving optimal results for your product – and doing so long-term through the highest quality. However, years of continuous operation also mean that even high-quality parts wear out over time and must be serviced or replaced promptly. With HARTER After-Sales Service, we ensure process reliability: We support your system throughout its entire service life – from telephone support for technical questions and maintenance to the delivery and installation of spare and wear parts. We also assist you with potential modifications to your system, for example, if you wish to dry a different product without having to install an entirely new system.

Engineering

Our strengths are ideas and experience. In collaboration with you as our client, solution options and variations for your individual drying requirements are developed. Through our project management, we guarantee a smooth process from planning, manufacturing, and assembly to final commissioning. As a client, you are welcome to be involved in the project planning at any time. This allows you to always view the current project status of your drying solution. Our project managers are happy to assist you with advice and support and are always available to listen to your concerns. Modern CAD workstations, years of experience in all fields, and motivated and trained employees ensure close integration of planning, design, and manufacturing.

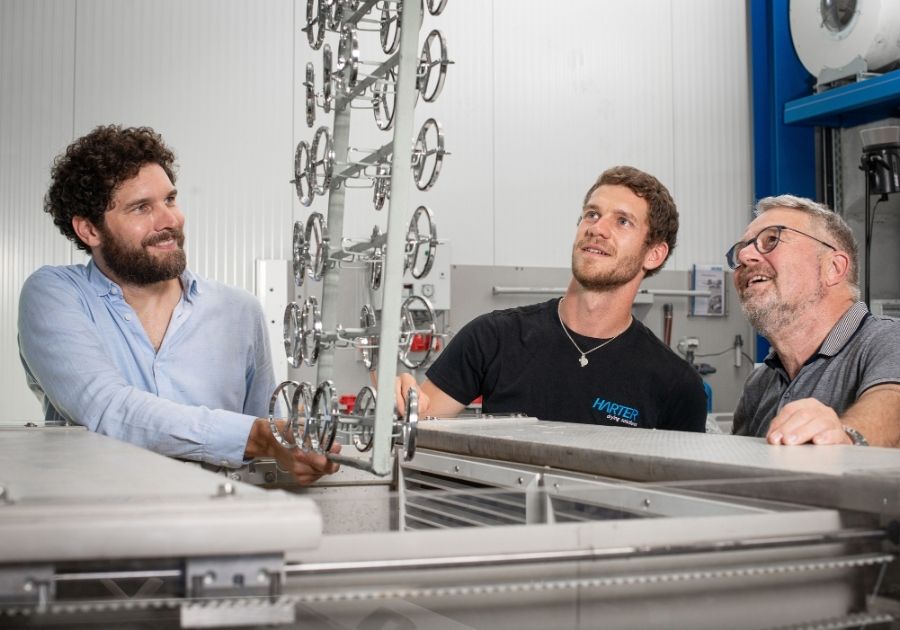

Qualification and Team Building

High product quality demands excellent employee qualifications. Therefore, we rely on young talent from within our own ranks and continuously train our employees. Training in commercial and technical professions has a long tradition with us. Profound expertise and the personal commitment of our employees are the foundation of our success. Regular communal activities also strengthen team spirit and bring us closer together as a team. A friendly atmosphere, attractive workplaces, and an idyllic environment complete the picture.

Quality in Every Aspect

Advantage through in-house production: In Stiefenhofen, we produce drying systems entirely in-house. Our specialized units – refrigeration plant construction, metal construction, plastics construction, electrical department with PLC programming and commissioning – ensure full control over every step. This way, we guarantee peak performance in quality, flexibility, and dimensional accuracy – from planning to the finished system.

CO₂ Saving - Government-funded

The German government's goal is to reduce CO₂ emissions by 65 percent by 2030 compared to 1990 and to achieve greenhouse gas neutrality by 2045. This largely affects the industry as well. Within the framework of these goals, the German government envisages a 60 percent reduction in CO₂ emissions through increased energy efficiency in electricity consumption by 2030. To support the achievement of the new climate targets, the Climate Protection Immediate Program 2022 was launched, providing approximately 8 billion Euros in additional funds for climate protection measures across all sectors in the coming years.

In this context, HARTER's condensation drying process offers a product within the highly energy-intensive field of industrial parts drying that provides a decisive advantage, not only ecologically but also economically:

– lower operating costs

– reduced resource consumption

– independence from fossil energy

– more stable process conditions

– significant CO₂ saving potential

Up to 75% Energy Cost Savings

At the heart of our drying systems is a highly efficient heat pump-based dehumidification technology. It is equipped with the best components, some specifically

developed for us, and first-class materials. We combine our air dehumidification with sophisticated air guidance. Because the driest air is only valuable if it is precisely directed to where it can absorb moisture. Only through the perfect interplay of these two components – air dehumidification and air guidance – does our drying achieve its full effect.

Our Airgenex® heat pump drying offers decisive advantages, not only ecologically but also economically:

— You gain quality

— You gain process reliability

— You save money

— You save resources

— You become independent of fossil energy and climatic influences