In food production, drying is a crucial process step: it influences taste, color, structure, shelf life, and nutrient content equally.

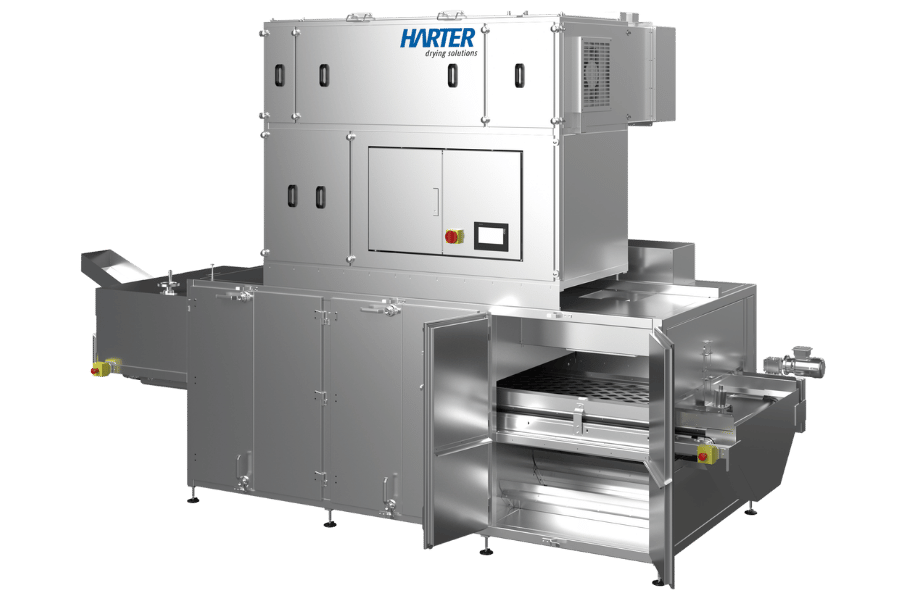

A HARTER belt dryer for food offers a precise, hygienic, and energy-efficient solution – ideal for fruit, vegetables, herbs, meat, and much more. The innovative heat pump technology ensures low temperatures, consistent results, and a closed, exhaust-free process.

How HARTER develops individual solutions for the food industry is shown in: Solutions for heat pump dryers are created this way.

An overview of the process is provided by: Energy-saving drying with heat pump.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

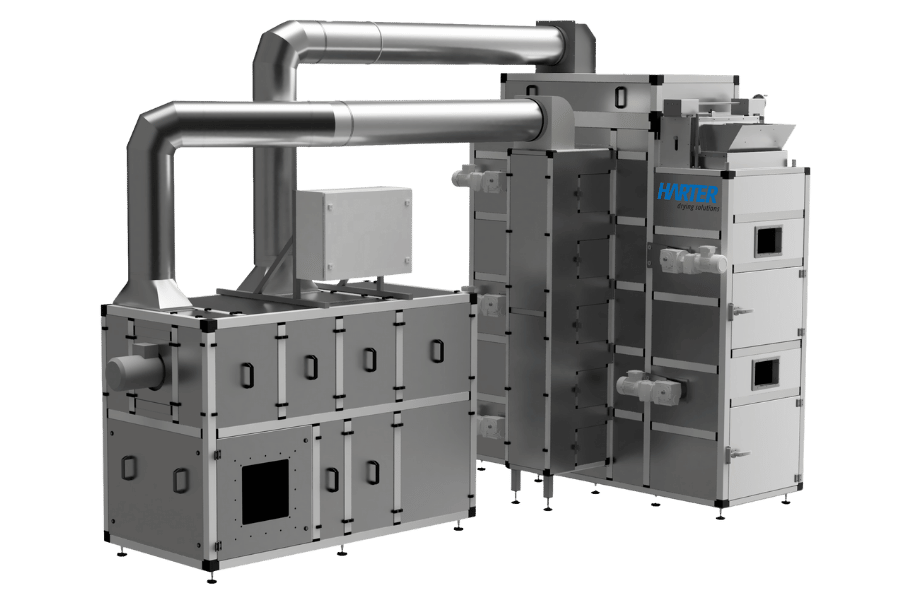

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

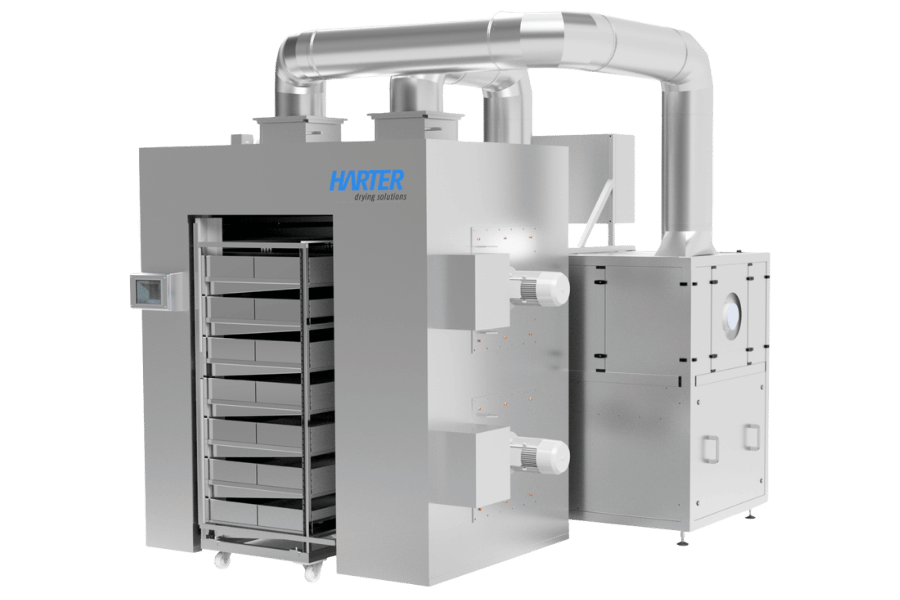

Belt dryer for food – Technology and process advantages

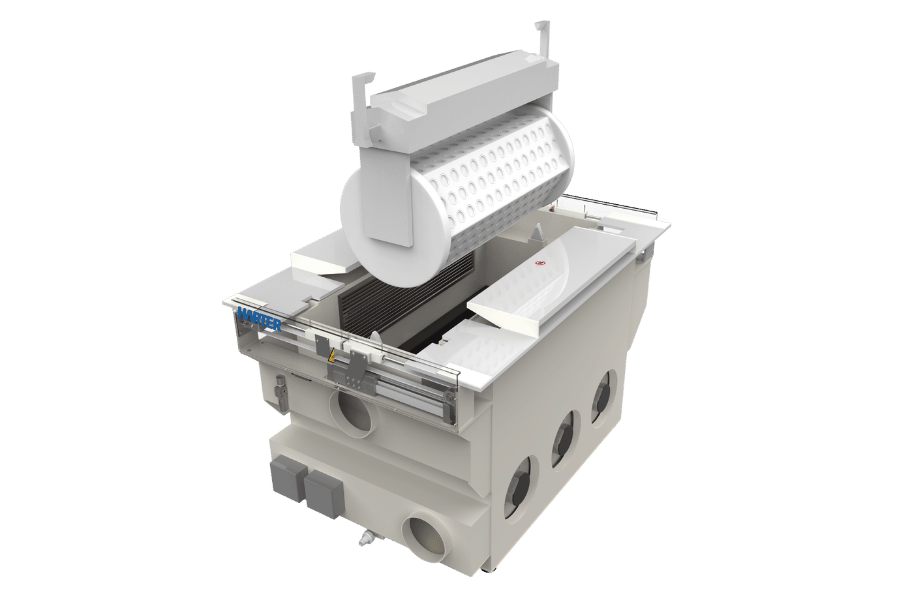

The HARTER belt dryer operates in a closed air circuit with a heat pump. The air is dehumidified, tempered, and reused – without exhaust air or energy loss. This allows food to be dried gently and hygienically at stable temperatures between 30 °C and 75 °C.

Advantages of the technology:

- uniform drying for homogeneous residual moisture levels

- Energy savings of up to 70% compared to hot air processes

- low temperatures for gentle treatment

- hygienic, exhaust-free system without dust or odors

- short drying times, high process stability

The controlled air flow preserves sensitive ingredients such as vitamins, pigments, and aromas. The result: natural color, intense taste, and longer shelf life – with low energy consumption at the same time.

How HARTER scales and optimizes drying systems is shown in: Expanding capacities with heat pump dryers.

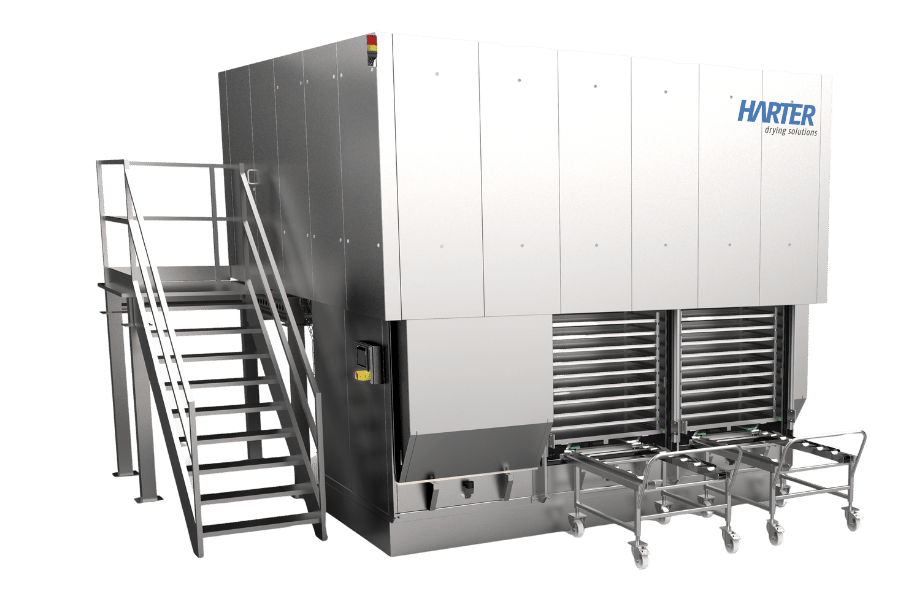

Belt dryer for food

Belt dryer for food – Applications and system variants

The belt dryers from HARTER are precisely tailored to the product, cut shape, volume, and line layout. They are suitable for batch operation as well as for continuous large-scale production.

Typical applications:

- Fruit and vegetables: apple rings, banana chips, berries, tomatoes, onions, peppers

- Herbs and spices: parsley, basil, chives, dill

- Meat and protein products: jerky, snack cubes, pet food

- Specialty products: mushrooms, algae, flowers, or superfood ingredients

System options:

- Single or multi-belt systems for various product shapes

- vertical or horizontal air flow depending on product stacking

- fully automatic control with temperature and humidity monitoring

- stainless steel construction for hygienic production

Before series production, your original products are tested in the company’s own technical center. There, optimal process parameters such as air velocity, temperature, and residual moisture are validated. These results form the basis for a safe, GMP- or HACCP-compliant series system.

Further related applications can be found under: Industries.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Belt dryer for food – Sustainability, energy efficiency, and hygiene

HARTER heat pump drying combines energy efficiency with the highest hygiene standards. Since the system operates without exhaust air, there are no odors or dust loads – a clear advantage for food companies.

Sustainable advantages:

- up to 70% lower energy consumption

- CO₂ reduction through heat recovery

- closed circuit – no exhaust air, no filters

- validatable process control according to food standard

- long-lasting, low-maintenance technology

HARTER systems are designed for 24/7 operation and are easy to clean. All parts in contact with the product are made of stainless steel, and the systems meet common food guidelines. Data logging, batch documentation, and interfaces to QS systems can be integrated on request.

How HARTER efficiently and individually realizes projects is shown in: Solutions for heat pump dryers are created this way.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently asked questions about belt dryers for food

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.