Pet food is a sensitive product that requires optimal drying. Product protection and safety are paramount during the drying process. Our integrated heat pump system, with its consistent process parameters, ensures reliable drying. Low temperatures simultaneously protect your products. The closed system of our pet food dryers delivers excellent results in terms of appearance, aroma, and bioactivity. For your drying requirements, our developed heat pump-based condensation drying, specifically the Airgenex®food dryer system variant, offers the optimal solution. On the following pages, you will learn more about the advantages of our pet food dryers, how they function, and their applications.

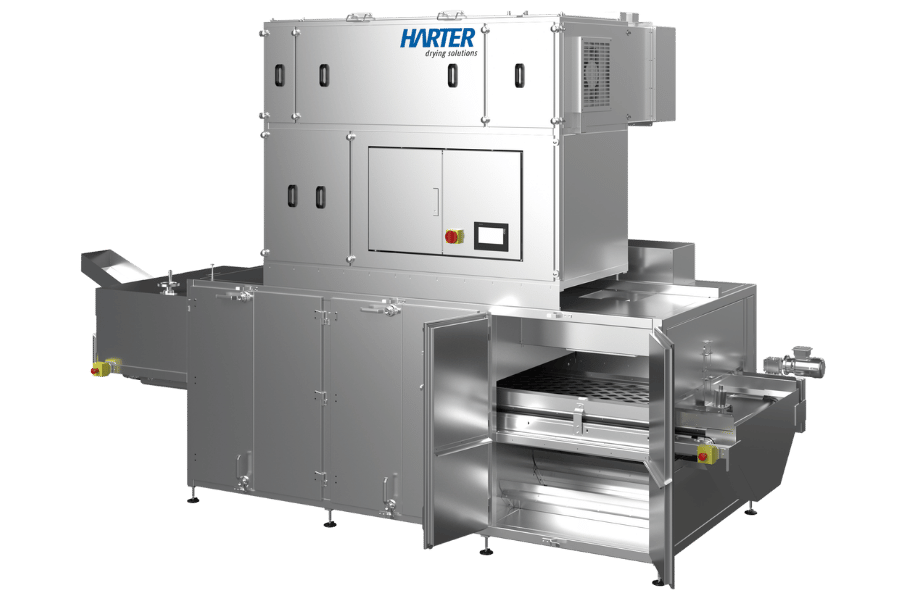

The drying of stand-up pouches, for example, has entirely different requirements compared to direct food drying. Here, the focus is on the complete and residue-free drying of surfaces. The parameter ‘time’ also typically plays a very significant role in packaging. You can find more about packaging drying here.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Your benefits

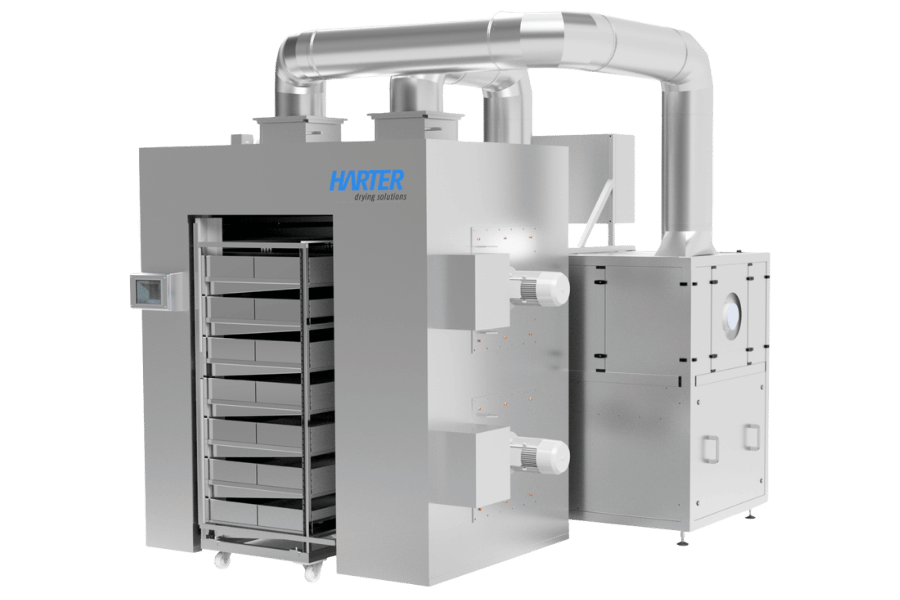

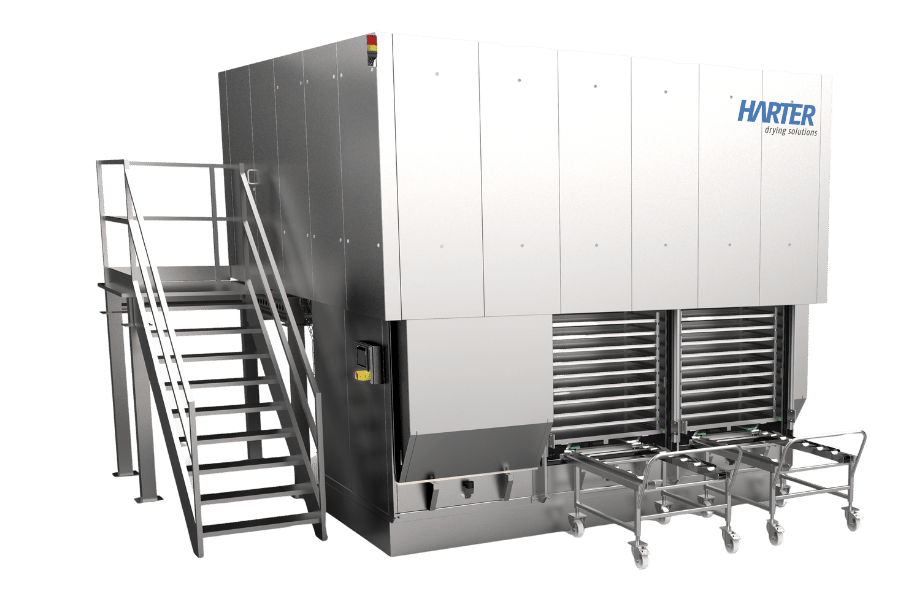

Drying Systems for Pet Food

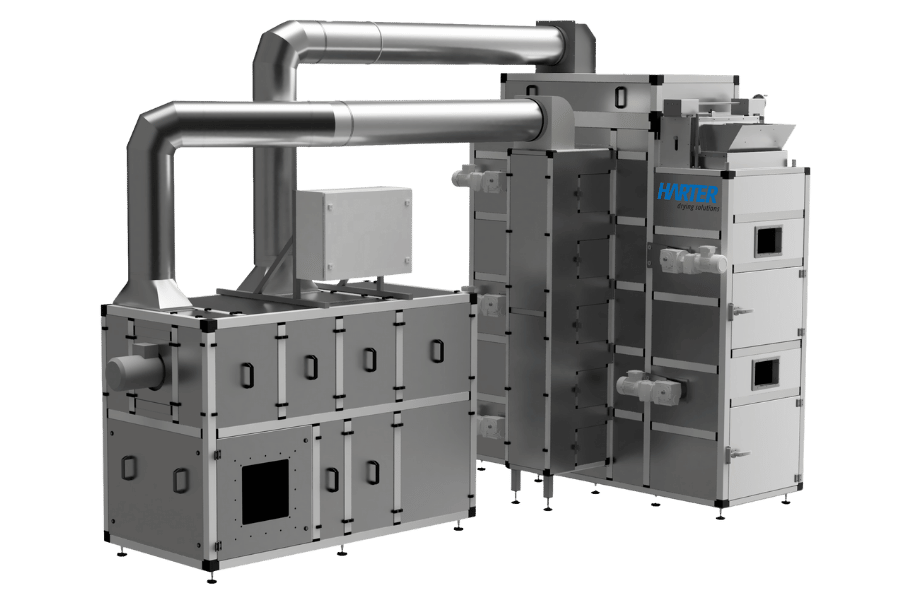

We develop and manufacture drying systems for both batch operation and continuous processes, thus adapting our technology to your specifications. We determine all specific parameters for successful drying beforehand in drying tests in our technical center.

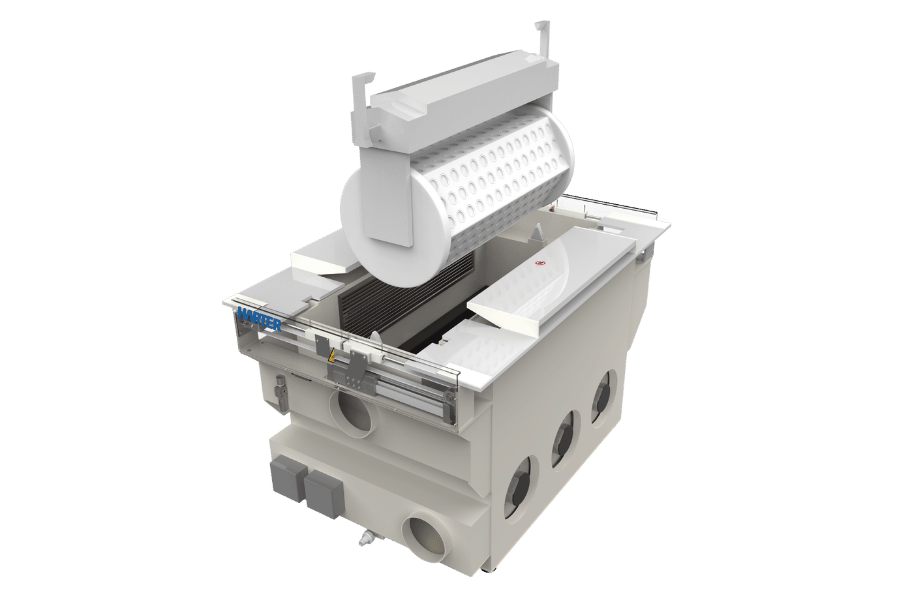

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.