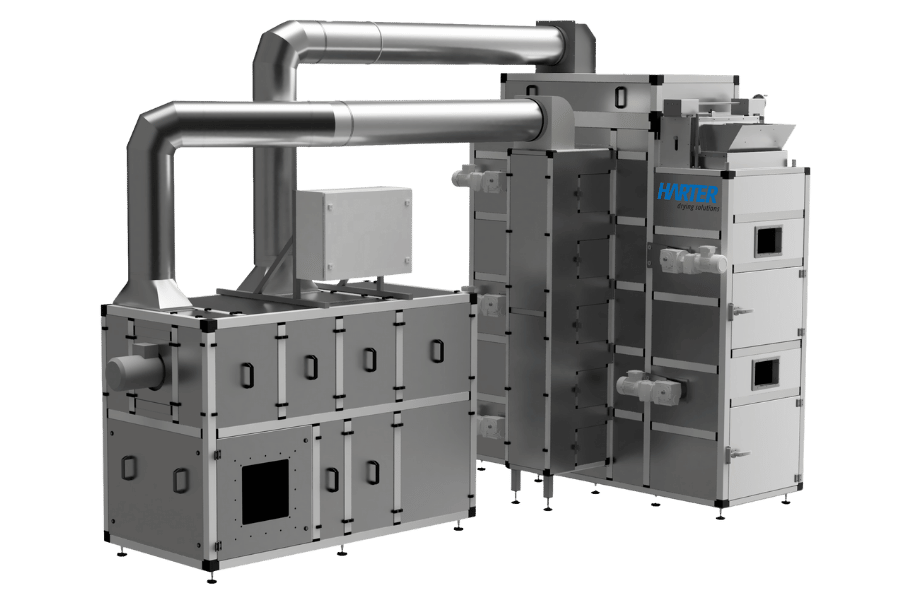

The Airgenex® coating dryers, specially developed by Harter, gently, energy-efficiently, safely, and quickly dry all types of surfaces and solids. These heat pump dryers utilize condensation drying. They resolve drying challenges after coating and optimize manufacturing processes.

Below, you will learn more about the advantages of our coating drying technology, how it works, and where it is applied – regardless of whether you are an end-user, plant manufacturer, or engineering firm.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Your benefits

Drying Systems for Coated Surfaces

Our dryers for coating applications are always custom solutions. They are available as batch dryers or continuous systems – all tailored to your product, your process, and your available space.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.