Arzneimittel und Medizinprodukte, verpackt und nicht-verpackt, sind hochsensible Güter und bedürfen bei ihrer Herstellung beziehungsweise Weiterverarbeitung bester und vor allem stressfreier Behandlung. Eine hochwertige Trocknung von Pharma / Medizintechnik bedeutet mehr Qualität und mehr Sicherheit. Die Trocknung auf Wärmepumpenbasis ist die Lösung – auch für Ihre Trocknung von Pharmazeutika. Medizintechnische Produkte trocknen mit abluftfreier Kondensationstrocknung – durch ihren physikalisch alternativen Ansatz kombiniert sie scheinbar widersprüchliche Attribute wie niedrige Temperaturen, kurze Trocknungszeiten und beste Ergebnisse.

Wenn Sie erfahren möchten warum unsere Art der Trocknung für Sie beziehungsweise für Ihren Kunden gut ist, wie sie funktioniert und welche Trocknungsanlagen wir realisieren, dann finden Sie hier alle wichtigen Informationen.

Unsere Trocknungslösungen sind auch für die kontrollierte Trocknung von medizinischem Cannabis geeignet – effizient, sicher, GMP-ready. Für hochqualitative Ergebnisse und konstante Prozesse.

Sie benötigen eine Individualanfertigung und/oder möchten den Trocknungsprozess vorab prüfen?

Entwicklung mit Praxistests im hauseigenen Entwicklungszentrum

Wir sind ein innovationsfreudiges Team und freuen uns über neue Aufgaben. HARTER prüft Ihre Individualanfertigung im Technikum unter realistischen Bedingungen, optimiert die Parameter und hält die Resultate nachvollziehbar fest. Nehmen Sie mit uns Kontakt auf – wir beraten Sie gerne und unverbindlich!

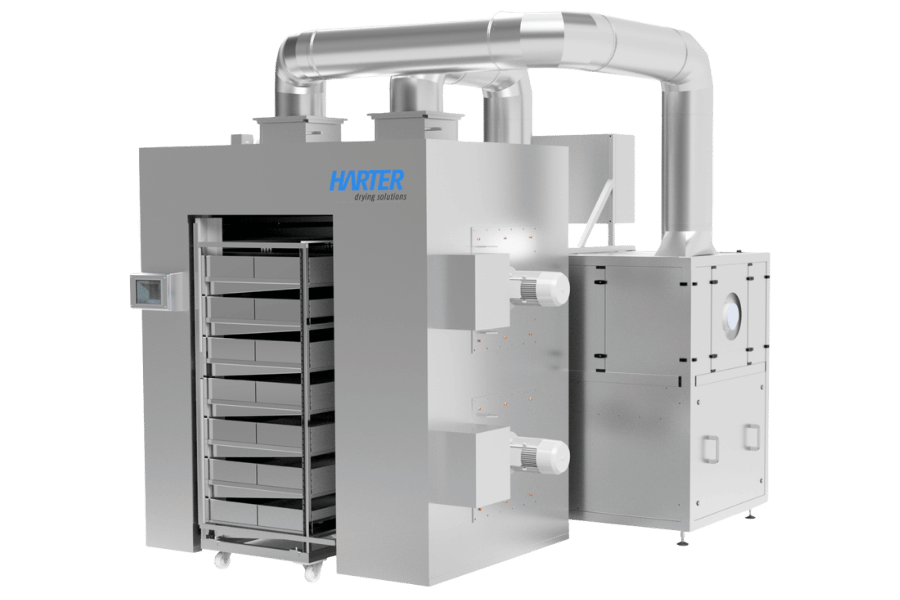

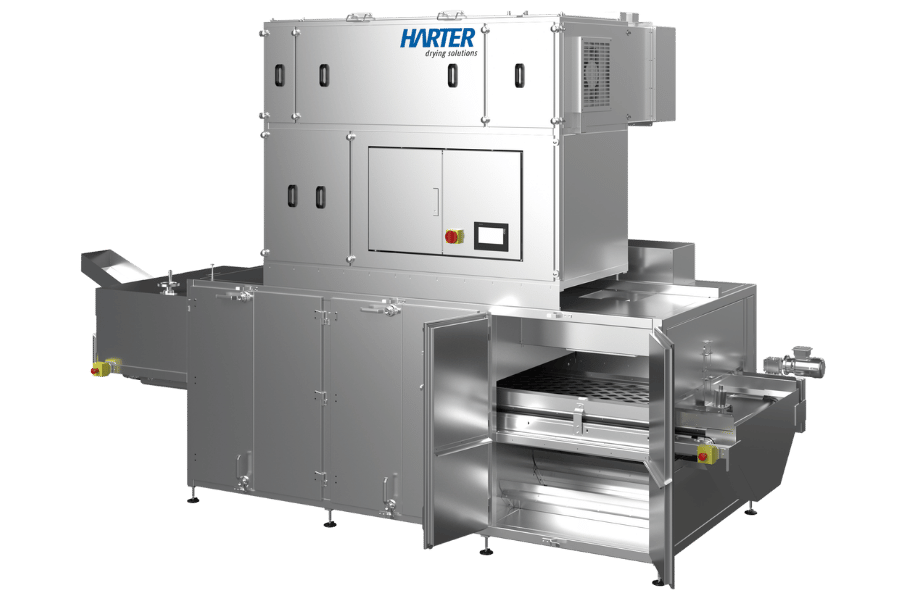

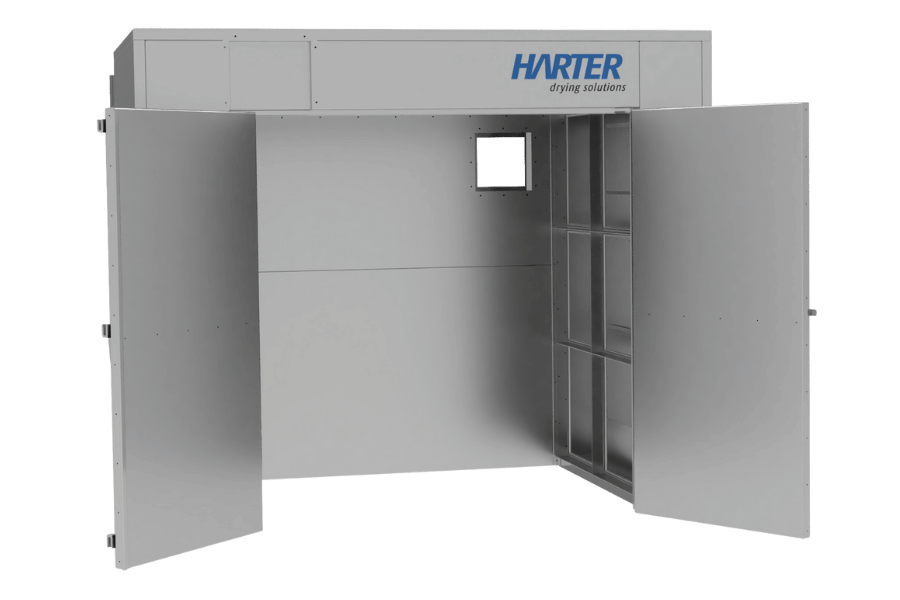

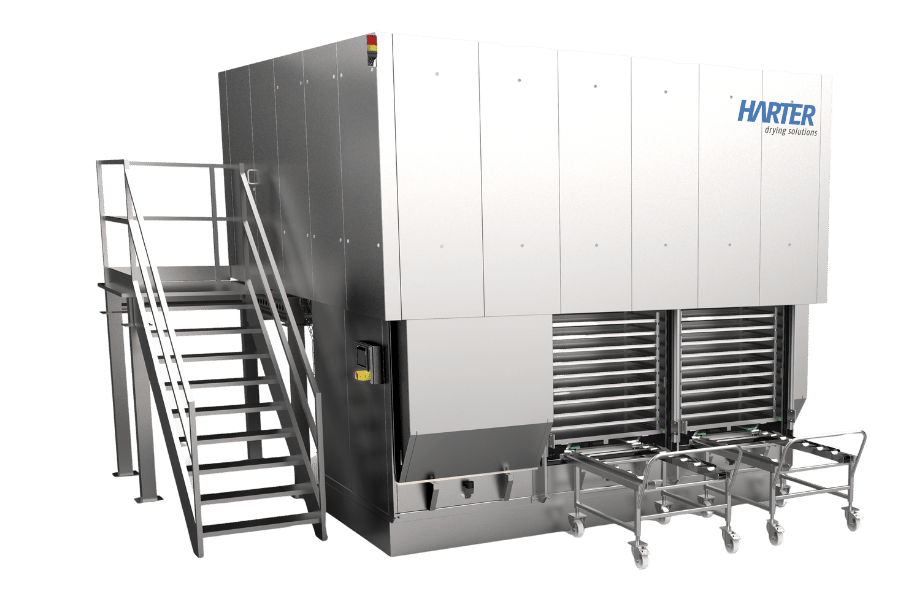

Trocknungsanlagen

in über 20 Ländern stehen für unsere Qualität

Mitarbeiter

aus allen Bereichen sorgen für eine hohe Fertigungstiefe

Jahre Erfahrung

in der Entwicklung innovativer Trocknungsanlagen

Ihr Nutzen

Trocknungsanlagen für Pharma & Medizintechnik

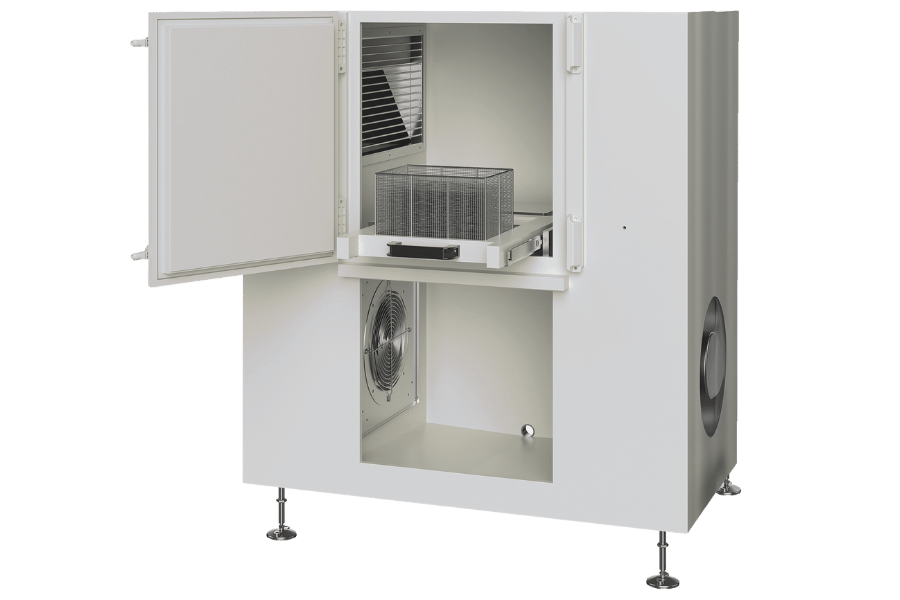

Wir entwickeln und fertigen Trocknungsanlagen sowohl für den Chargenbetrieb als auch für kontinuierliche Prozesse und passen somit unsere Technologie Ihren Vorgaben an. Alle spezifischen Parameter für eine erfolgreiche Trocknung ermitteln wir vorab in Trocknungsversuchen in unserem Technikum.

Wir trocknen mit trockener Luft und bringen sie an die richtigen Stellen: Ein perfektes Zusammenspiel aus Luftaufbereitung und Luftführung liefert Ihnen das bestmögliche Trocknungsergebnis.

Zuverlässig – Kompetent – Langfristig

Service, der weiterdenkt – über Jahre hinweg

Mit dem HARTER After-Sales Service sichern Sie sich eine langfristig zuverlässige und leistungsfähige Trocknungslösung. Ob Wartung, Ersatzteilversorgung oder technische Anpassungen – wir betreuen Ihre Anlage über den gesamten Lebenszyklus hinweg und sorgen dafür, dass sie jederzeit optimale Ergebnisse liefert.

Das sagen unsere Kunden

„Manchmal ist es besser nichts zu sagen, und seine Kunden für sich sprechen zu lassen.“

– Regina Mader, Geschäftsführerin

Füllen Sie jetzt das Formular aus und wir werden uns schnellstmöglich mit Ihnen in Verbindung setzen.

Broschüren, Fachberichte und Presseartikel für alle, die es genauer wissen wollen.