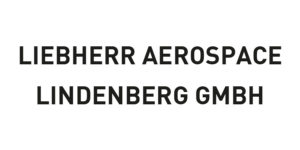

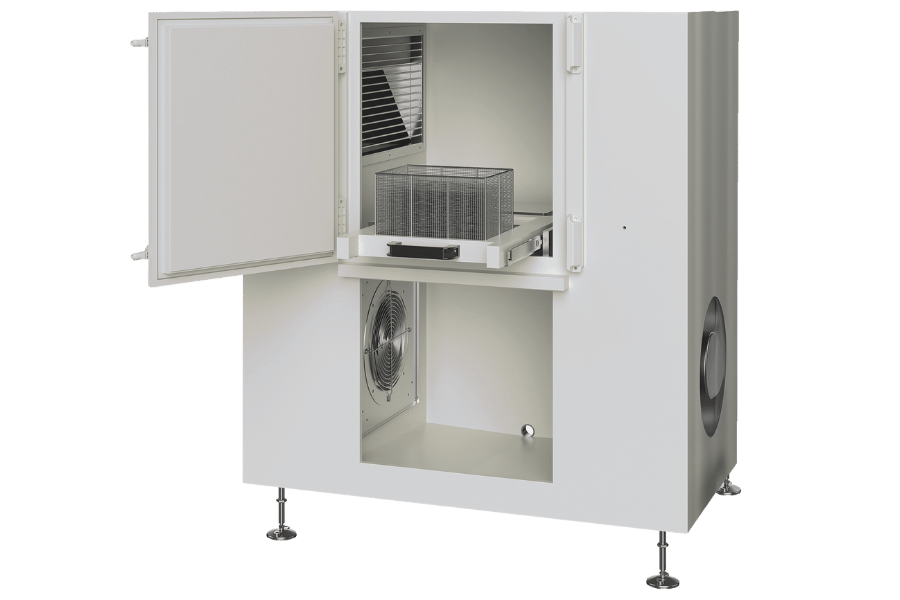

The Airgenex® drying system with heat pump, developed by Harter, offers an innovative solution for the gentle, safe, and energy-efficient drying of surfaces and solids of all kinds. This means that this special form of condensation drying solves even complex drying problems and contributes to the optimization of manufacturing processes – also in industrial drying after cleaning. Energy-saving drying will become increasingly important in the future.

In particular, thanks to the closed air circuit with heat pump, the Airgenex® technology enables fast and uniform drying at low temperatures – ideal for sensitive materials and demanding applications.

Learn more about the advantages of our drying technology, its functionality and the diverse areas of application – regardless of whether you are a user, plant manufacturer or a planning office.

Robust – Efficient – Application-oriented

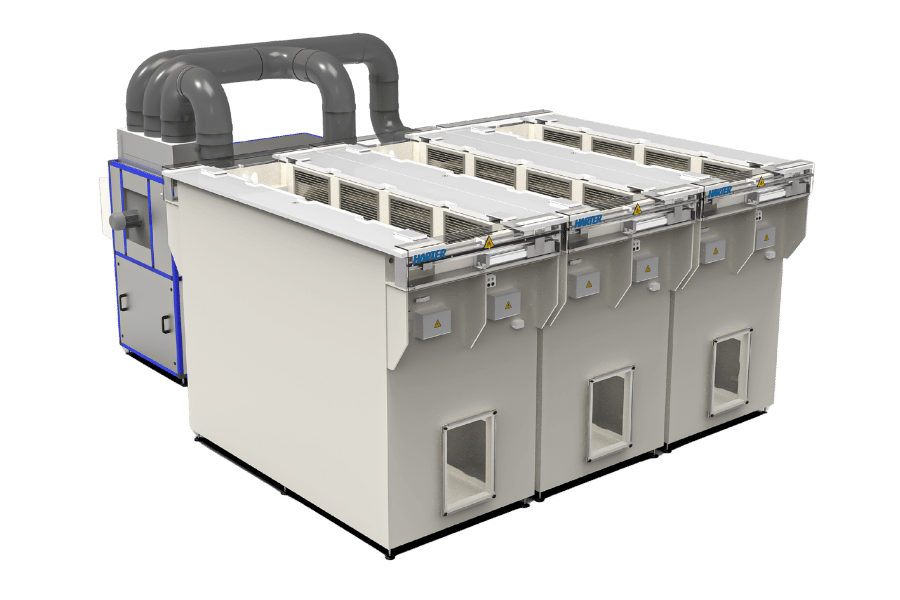

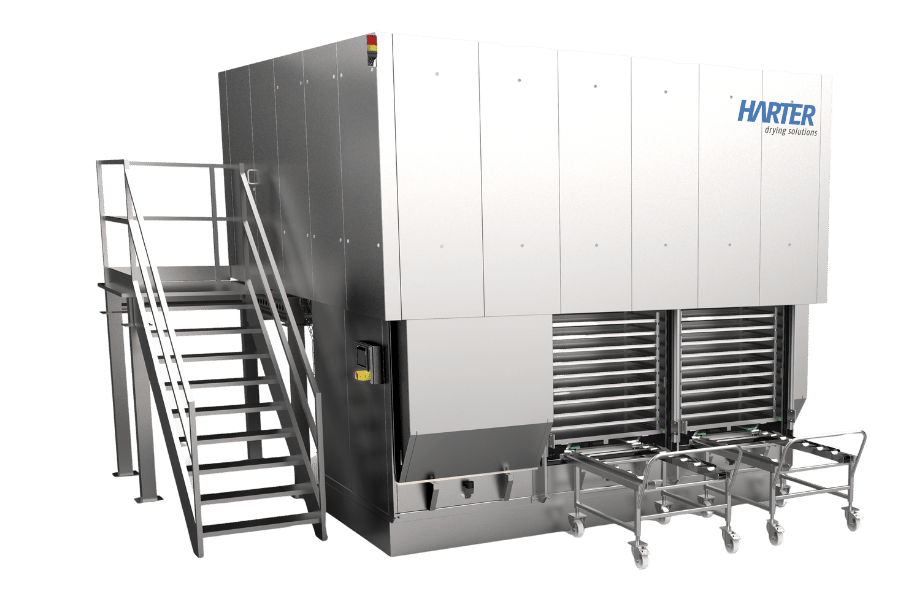

Drying of industrial products

Reliable drying after cleaning, coating or processing of industrial workpieces.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Your benefits

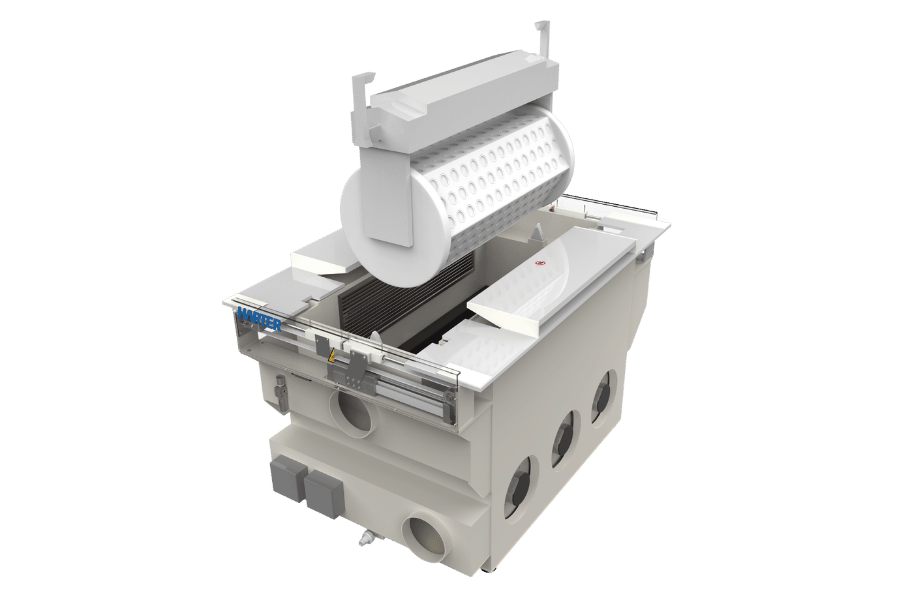

Drying systems for surfaces

Whether bulk material directly in the drum, rack goods with complex geometry or continuously conveyed components – each application places its own demands on the drying technology. In other words, depending on the drying process and material type, different factors are decisive for an effective and process-reliable drying process.

With the Airgenex® technology, we offer you customized solutions for a variety of industrial drying applications. Our drying systems are flexibly adaptable, highly efficient and suitable for a wide range of industries.

If you have not found your application here, please contact us directly.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.