In industrial processes, drying is a crucial step for product quality, energy consumption, and process reliability. The industrial heat pump dryers from HARTER combine maximum efficiency with consistent process stability – regardless of outside temperatures or humidity.

The systems dry a wide variety of materials – from metals and plastics to pharmaceutical and chemical products and food – in an energy-efficient and cost-effective manner.

How HARTER develops the right concepts is described in How solutions for heat pump dryers are created.

A practical overview of the possibilities is provided by Energy-saving drying with heat pump.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Industrial Heat Pump Dryers – Technology, Principle, and Advantages

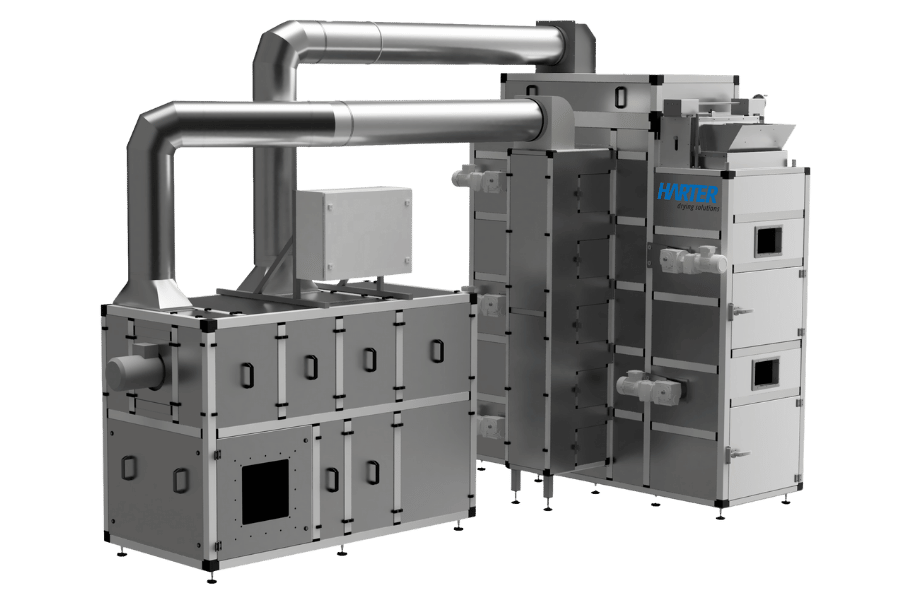

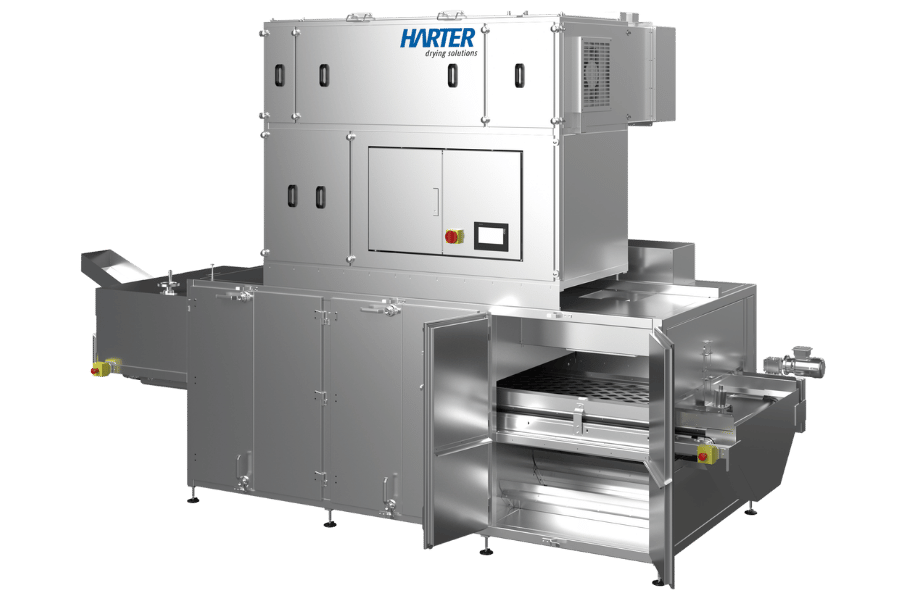

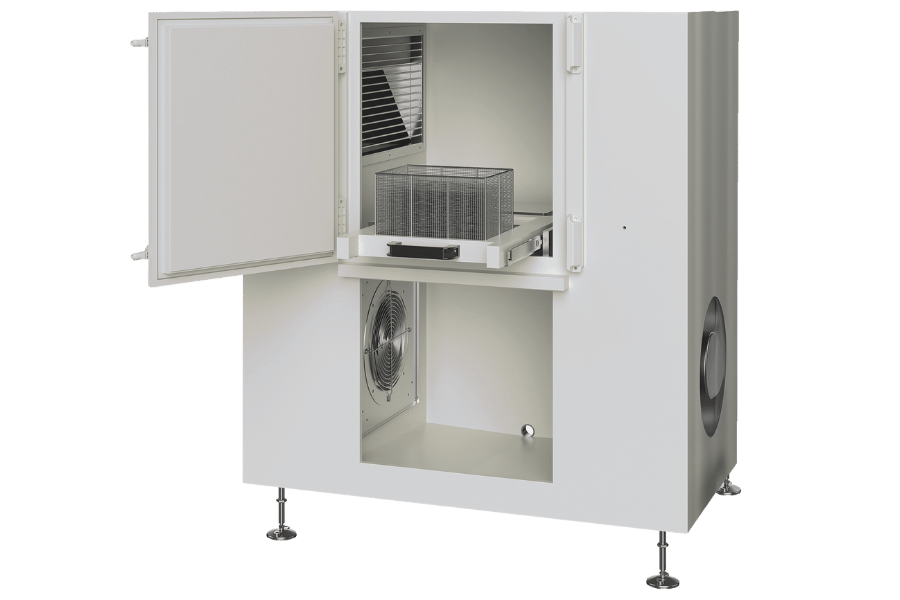

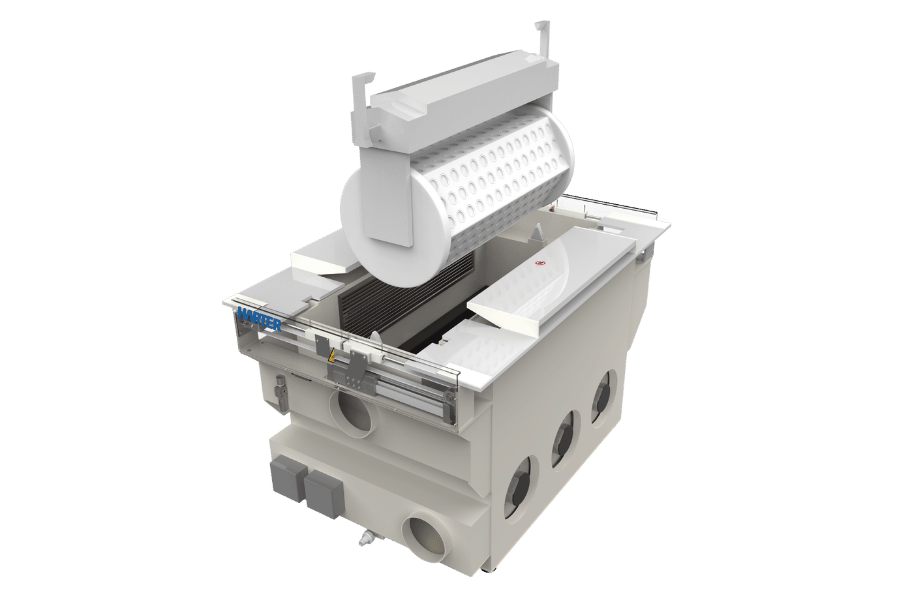

The core of the HARTER technology is a closed air circuit with an integrated heat pump.

The air is dehumidified, heated, and recirculated over the product – without any fresh air or exhaust air. This keeps the process stable, clean, and independent of the environment.

This technology enables:

- uniform drying at temperatures between 20 °C and 75 °C,

- energy savings of up to 70% compared to hot air systems,

- excellent process reliability for sensitive materials,

- CO₂ reduction through heat recovery.

You can find a practical example of capacity increase in production in the article: Expanding Capacities with Heat Pump Dryers.

The heat pump technology from HARTER is used in a wide variety of industrial sectors – such as the food, chemical, pharmaceutical, and surface technology industries. Each application is individually adapted to optimally balance energy requirements, drying time, and system layout.

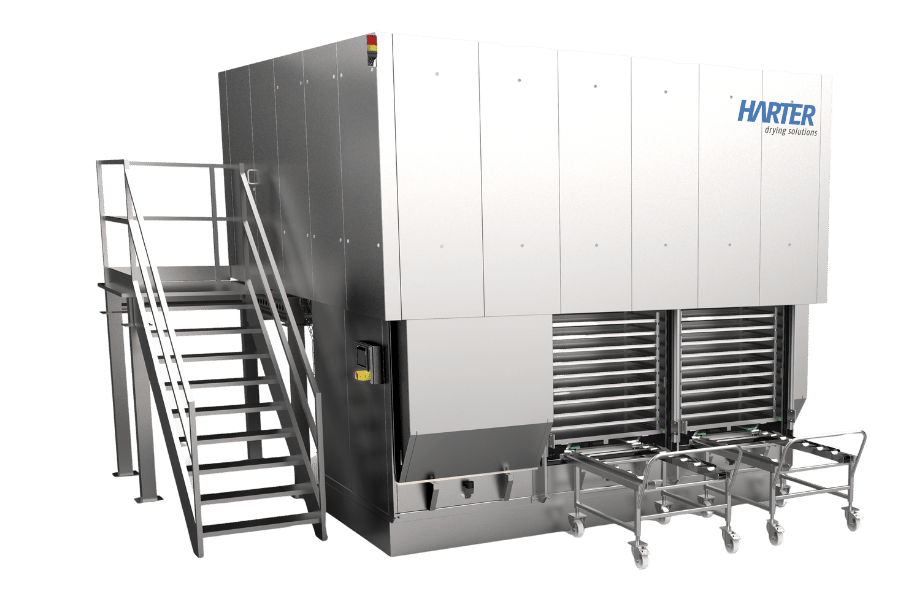

Industrial Heat Pump Dryers

Industrial Heat Pump Dryers – Applications, Integration, and Flexibility

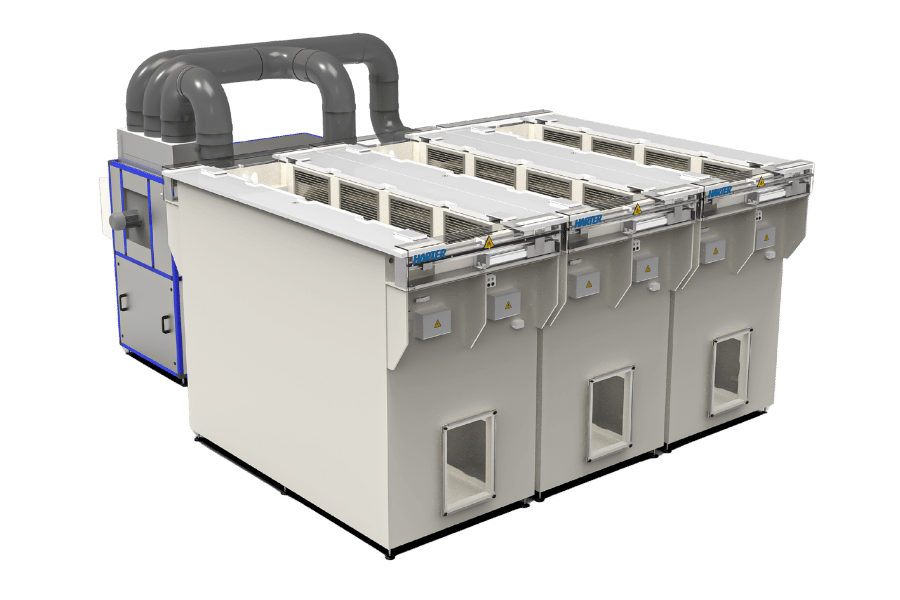

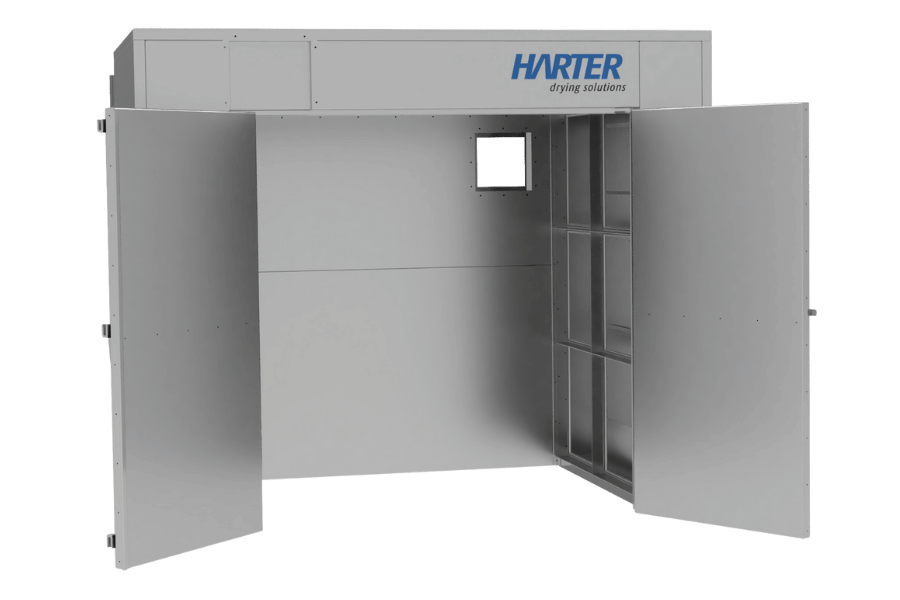

HARTER’s systems cover a wide range of industrial requirements. Thanks to their modular design, they can be easily integrated into existing production lines.

Typical areas of application include:

- Surface and electroplating drying,

- Powder, granulate, or solid matter drying,

- Sewage sludge and sludge residue drying,

- Food and pharmaceutical production.

HARTER develops a precisely coordinated concept for every application – from laboratory to large-scale plant dimensions.

Test runs under real conditions in the company’s own technical center provide reliable data on temperature, air flow, and residual moisture.

This provides you with a reproducible, validated result – the basis for economical series production.

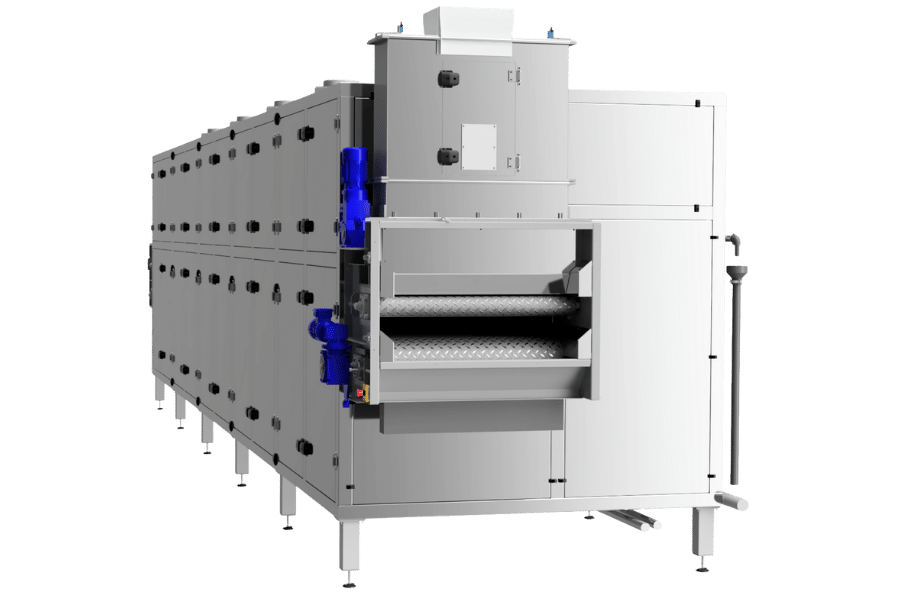

Depending on the product type, different drying systems are available:

- Chamber dryers/stack dryers for flexible batch processes (Industrial stack dryers/chamber dryers)

- Belt dryers for continuous production lines (Industrial belt dryers)

- Tunnel dryers for high throughput rates (Industrial tunnel dryers)

This allows even demanding drying tasks such as metal, plastic, or powder processing to be implemented safely, efficiently, and consistently.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Industrial Heat Pump Dryers – Sustainability, Economy, and Future Security

Sustainability is an integral part of technology development at HARTER. The closed air circuit minimizes energy losses and prevents emissions. The waste heat is recovered in the system, which significantly improves the CO₂ balance of the plant.

HARTER dryers meet the highest demands for:

- Energy efficiency (low electricity and heat requirements),

- Process and product safety,

- Economy through short amortization periods,

- Certifiability according to ISO 50001 and HACCP requirements.

By combining with renewable energies such as photovoltaic systems or heat recovery systems, additional savings potentials can be unlocked. A comprehensive overview of the industry solutions is available at: Industries.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently Asked Questions about Industrial Heat Pump Dryers

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.