The production of high-quality pet food requires precise, reproducible, and hygienic drying. Whether snacks, chews, meat pieces, or plant-based mixtures – the moisture must be uniformly reduced without affecting flavors, color, or nutrients. HARTER’s heat pump drying systems offer an ideal solution for this: energy-efficient, exhaust-free, and perfectly controllable.

With HARTER, you ensure the quality, shelf life, and nutritional value of your products – regardless of weather or ambient air.

How HARTER develops customized processes is shown in: How Solutions for Heat Pump Dryers are Created.

Fundamentals and practical knowledge about the technology can be found under: Energy-Saving Drying with Heat Pumps.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Pet Food Dryers – Operating Principle and Technology

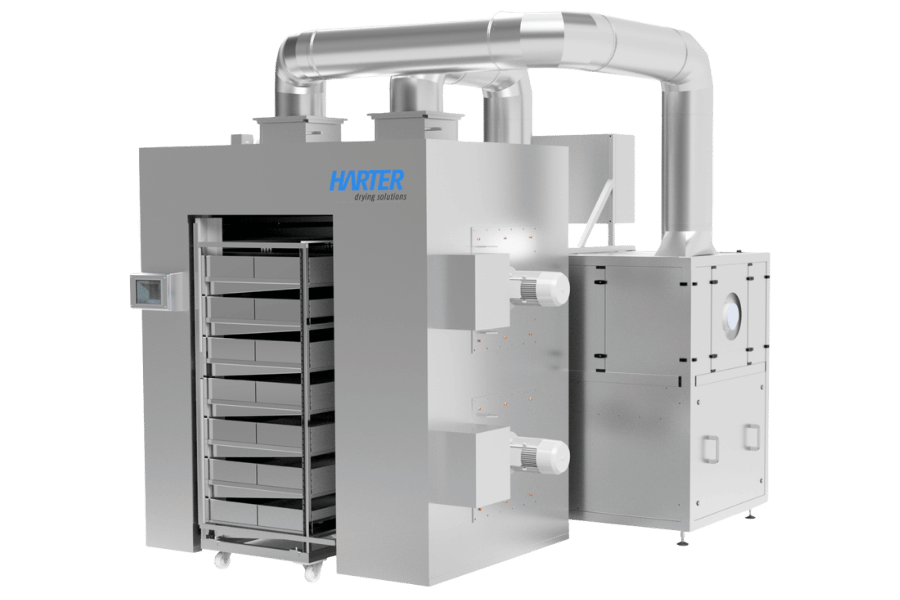

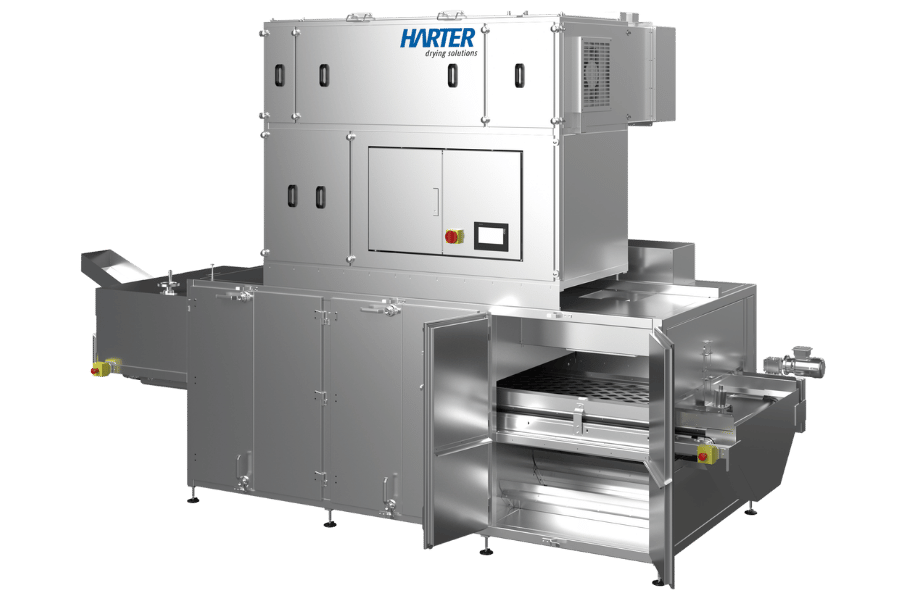

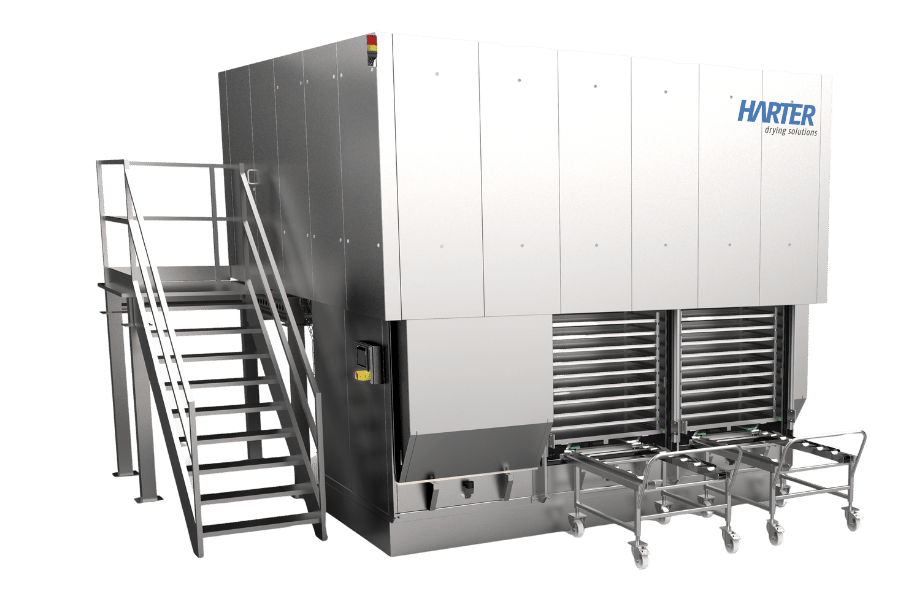

In the closed air circuit of HARTER systems, the process air is dehumidified, heated, and recirculated over the product. This creates a controlled environment where temperature and relative humidity remain consistently low – ideal for sensitive raw materials such as meat, offal, grains, or plant-based proteins.

Your Advantages at a Glance:

- Gentle drying at 30 – 75 °C, depending on the product

- Preservation of flavors, color, and nutrients

- Exhaust-free and hygienic, no dust ingress or cross-contamination

- Up to 70% energy savings compared to hot air processes

- Uniform residual moisture through controlled air guidance

- Constant process conditions regardless of season or climate

The combination of heat pump and controlled dehumidification prevents case hardening or overheating. This allows both protein-rich and plant-based feedstuffs to dry stably and gently.

Insights into scalable solutions are offered in: Expanding Capacities with Heat Pump Dryers.

Pet Food Dryers

Pet Food Dryers – Applications and Product Variety

The drying of pet food requires differentiated process control:

Moisture, density, and structure of the raw products vary greatly. HARTER designs each system individually – from pilot scale to industrial series production.

Typical applications:

- Meat and chew snacks (e.g., beef lung, chicken breast, treats)

- Dry food for dogs, cats, or small animals

- Plant-based feed components from peas, potatoes, corn, or soy

- Protein mixtures and insect flours

- Feed additives and functional ingredients

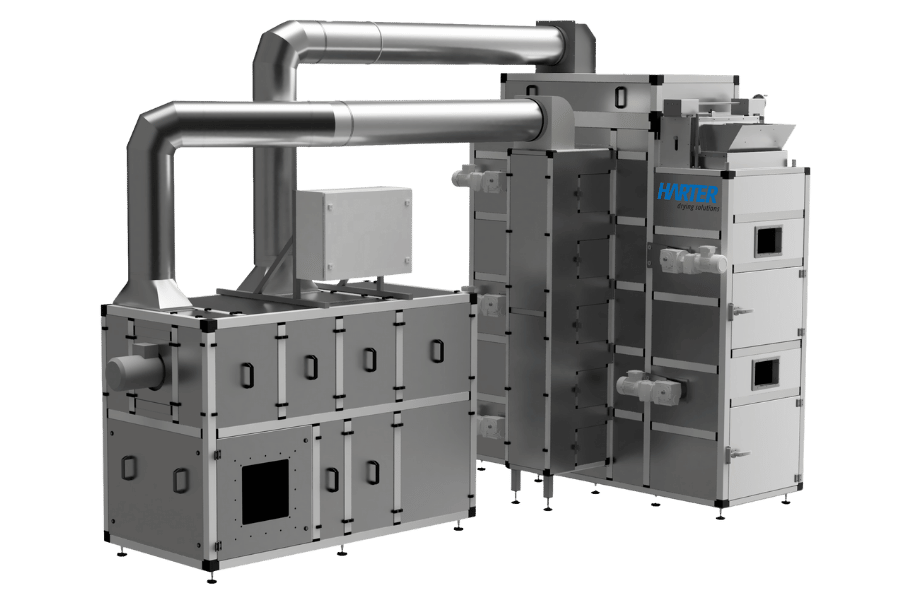

System types:

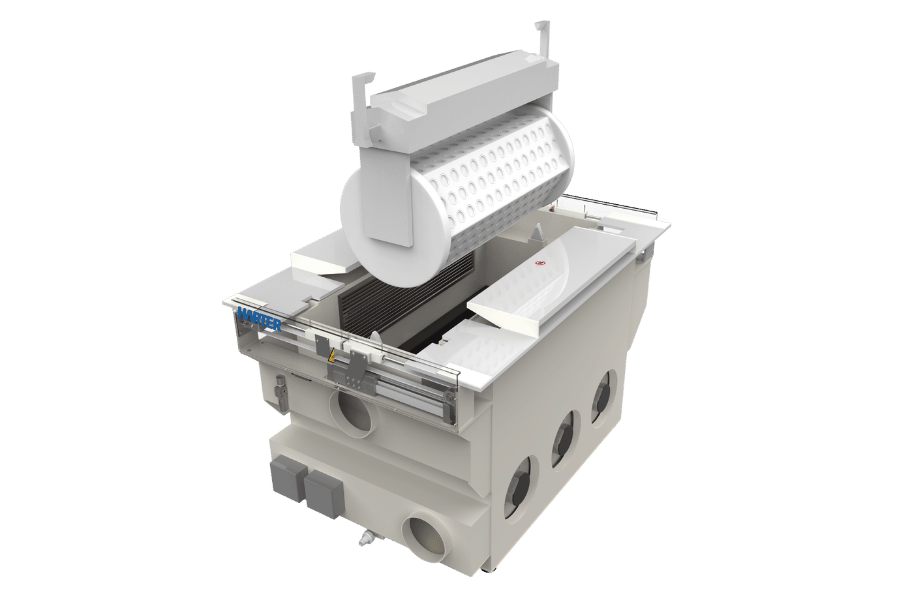

- Chamber dryers/Tray dryers for batch production

- Belt or tunnel dryers for continuous lines

- Hygienic special designs for food-grade standards (stainless steel, easy to clean)

Before each design, HARTER tests your original products in its in-house technical center. There, temperature, air flow, bed height, and target residual moisture are determined – forming the basis for a reproducible process.

Further information on related application areas can be found under: Industries.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Dryers for pet food – Sustainability, hygiene, and efficiency

The production of pet food demands not only quality but also energy efficiency and process hygiene.

HARTER’s heat pump technology fulfills both: It drastically reduces energy consumption and operates completely exhaust-free.

Sustainable advantages:

- Up to 70% less energy consumption through heat recovery

- Reduced CO₂ emissions and no exhaust emissions

- No filter or exhaust systems required

- Long service life with minimal maintenance

- Eligible technology according to efficiency guidelines

The systems meet the highest hygiene standards (HACCP, GMP-compliant) and are easy to clean. Furthermore, integration into existing production lines is possible – from raw material input to packaging.

How HARTER develops standardized solutions from individual requirements is shown in: How Solutions for Heat Pump Dryers are Created.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently Asked Questions about Pet Food Dryers

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.