Drying and flashing off water-based paints in the painting line takes much time and energy. Heat pump based condensation drying provides an efficient process. The technique provides a combination of low temperatures and extremely dry air in a closed air system.

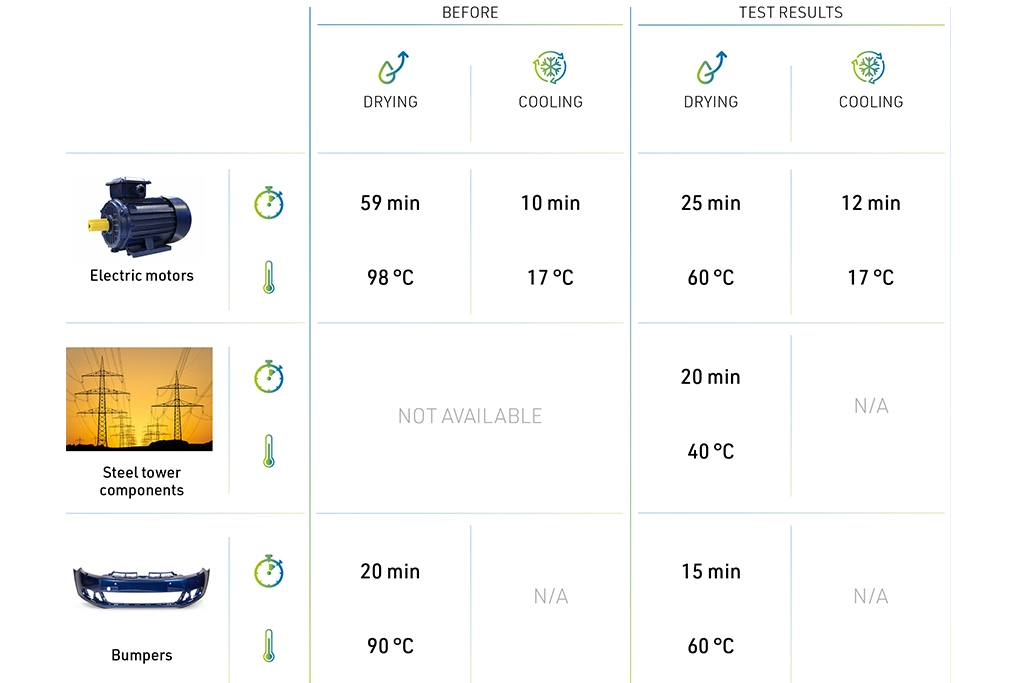

Harter developed their heat pump based condensation drying technique more than 30 years ago and has optimized it ever since. The German company banked on an in-house Test Center from the first to conduct feasibility tests and to determine parameters. Prospective customers may satisfy themselves of the effi ciency of low temperature drying and have their components tested for response to the parameters temperature, time, humidity, air speed and airflow rate. Several multifunctional dryers are available for diverse process types. The test series provide information relating to the drying properties of the specific product. Following an exhaustive preliminary exchange, two engineers conduct the tests. Then, the drying specialists analyse the results and prepare a report. All these actions aim at achieving a solid basis for the layout and design of an appropriate drying system. Process changes, such as the use of water-based instead of solvent-based paint, are often the reason for trials in the Test Center. Here are some examples.

Read the complete report here.