Adhesion water drying is one of the crucial steps after galvanic, chemical, or mechanical cleaning processes. It significantly determines whether components come out of the line spot-free, corrosion-resistant, and ready for assembly. With the heat pump drying systems from HARTER, you achieve exactly that: reproducible, consistent, and energy-efficient results – even with complex component geometries.

The closed, exhaust air-free drying system operates independently of the ambient air and ensures constant process conditions in all seasons.

How HARTER develops individual solutions for industry and electroplating is shown by: This is how solutions for heat pump dryers are created.

The physical principles of the technology are described in: Energy-saving drying with heat pump.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Adhesion water drying – Functionality and advantages of heat pump technology

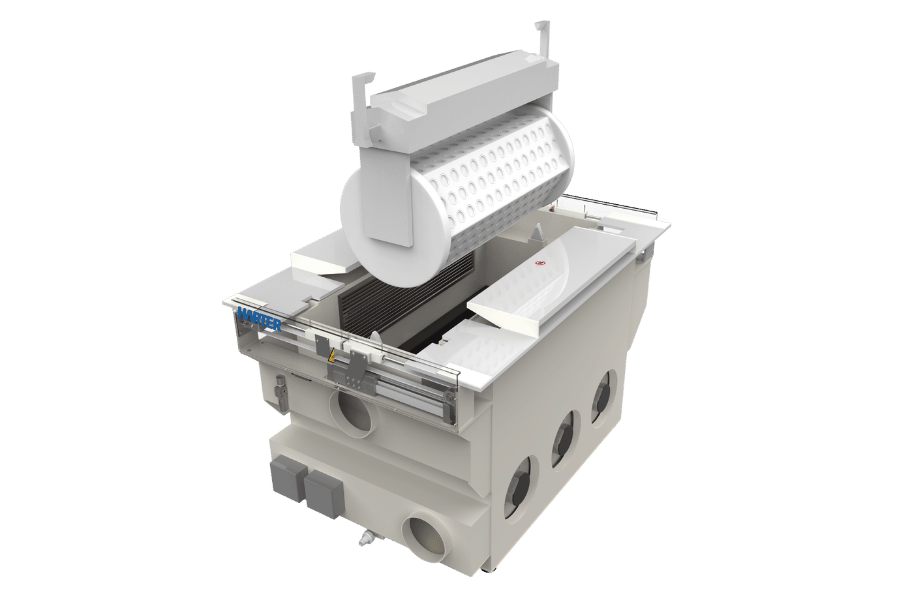

In adhesion water drying, the water adhering to the surface is gently removed after rinsing or cleaning processes. In contrast to conventional hot air, heat pump drying works in a closed circuit – without exhaust air, controlled, and resource-efficient.

The principle:

- The air is dehumidified, tempered, and guided over the product.

- The water evaporates without residue, without stains or traces of oxidation.

- The heat generated in the process remains completely in the system – without energy loss.

Your Benefits:

- Spot-free, uniform drying even with undercuts

- Process-safe and independent of the ambient air

- Temperature-gentle (30 – 75 °C)

- Up to 70% energy savings compared to hot air systems

- Absolutely exhaust air-free, no odor, no particle entry

Due to the precisely regulated humidity and temperature, even hard-to-reach areas dry reliably – a crucial factor in electroplating, medical technology, and the precision industry.

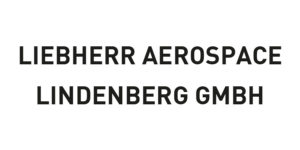

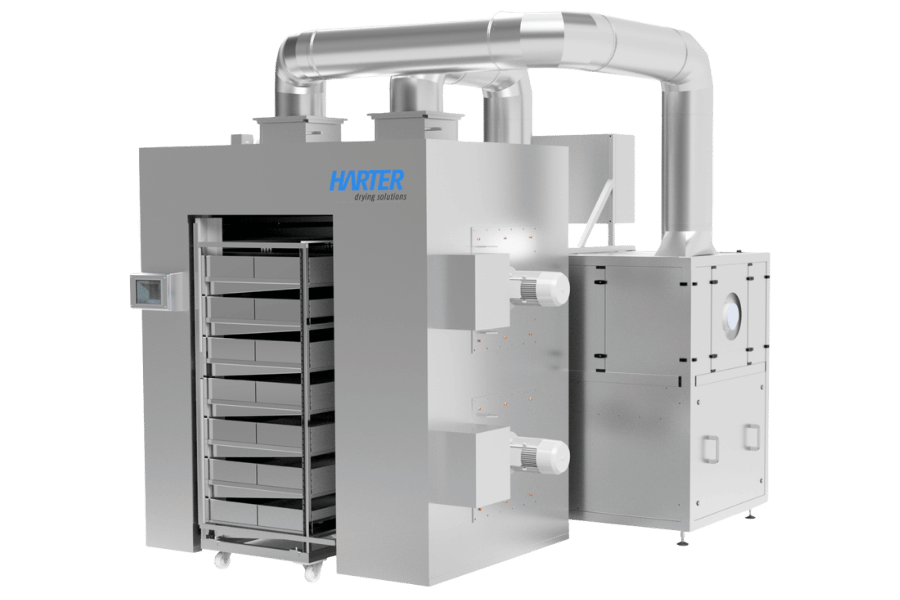

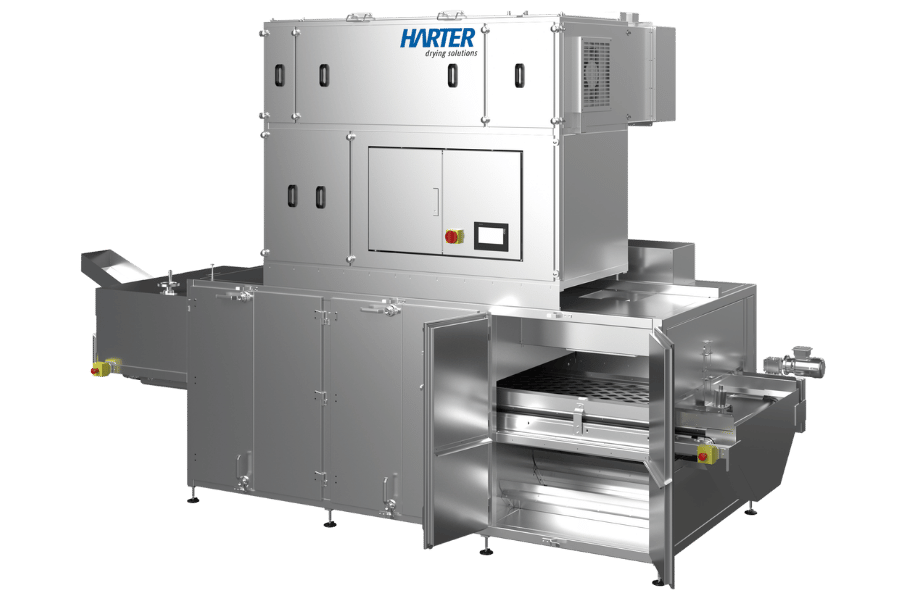

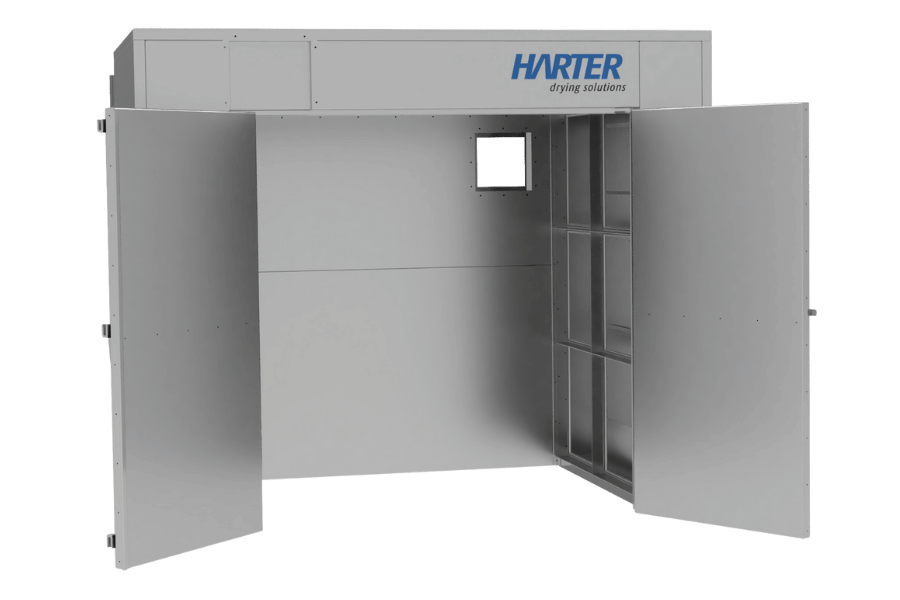

Drying systems for adhesion water drying

Adhesion water drying – Applications, industries, and system variants

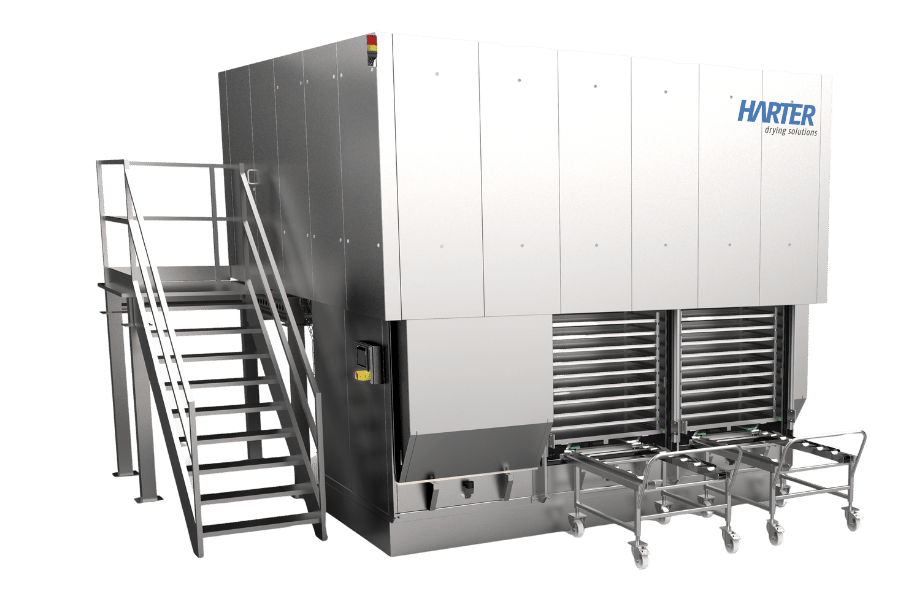

Adhesion water drying is used wherever components must be further processed free of residual moisture after cleaning, rinsing, or passivation. HARTER delivers individual solutions for small workpieces as well as for large-format components or series production.

Typical applications:

- Galvanic surface treatment (zinc, nickel, chrome, copper)

- Metal and plastic components with complex geometries

- Components with blind bores, gaps, or undercuts

- Workpieces after chemical degreasing or passivation

- Medical and precision parts, where cleanliness and appearance are crucial

System solutions:

- Chamber dryers for flexible batch processes

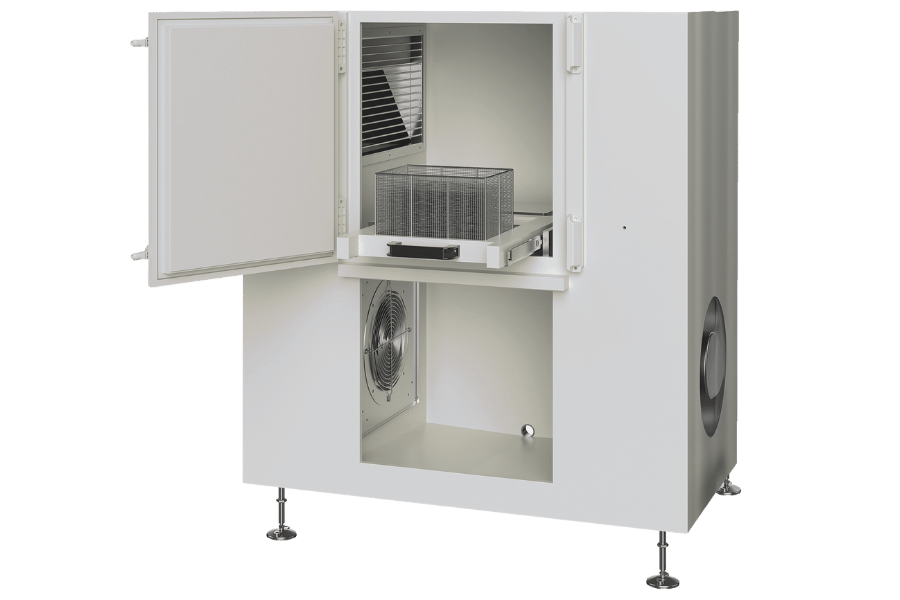

- Tray dryers for sensitive or small components

- Belt and tunnel dryers for automated electroplating lines

- Special systems for bulk goods or component carriers

Before realization, HARTER tests your original parts in its own technical center. There, air flow, temperature, time, and target residual moisture are precisely determined – the basis for a validated, reproducible series system.

Further industrial application fields can be found under Industries.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Adhesion water drying – Sustainability, economy, and process reliability

In addition to quality, sustainability also plays a central role. HARTER heat pump drying combines energy efficiency with process stability – a clear advantage for environmentally conscious companies.

Sustainable advantages:

- Up to 70% energy savings compared to hot air systems

- No exhaust air, no filter or exhaust air purification necessary

- Reduced CO₂ emissions due to closed circuit

- Long service life and low-maintenance operation

- Eligible technology according to energy efficiency guidelines

The systems can be easily integrated into existing electroplating or cleaning systems. Optionally, sensors, humidity monitoring, and data logging can be added for quality verification.

How HARTER develops series-ready solutions from individual requirements is described in: This is how solutions for heat pump dryers are created.

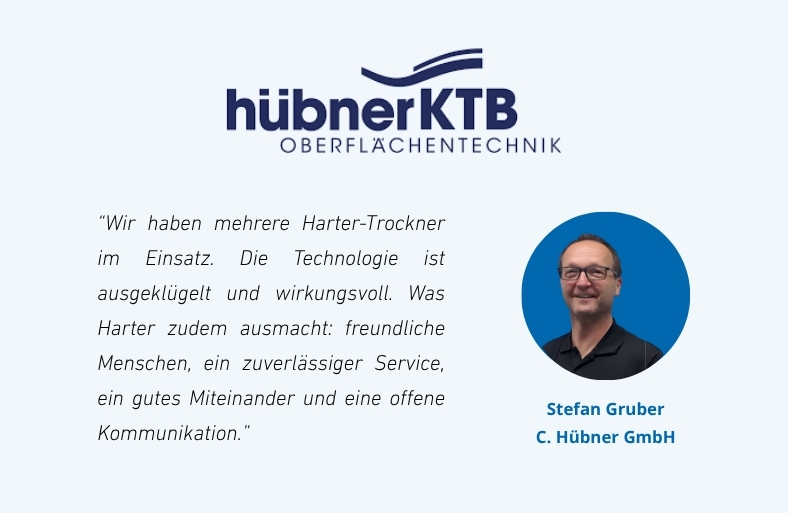

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently asked questions about adhesion water drying

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.