After the mechanical dewatering of sludge, a high residual water content often remains. The drying after chamber filter press is therefore crucial to reduce transport and disposal costs – and at the same time comply with environmental regulations.

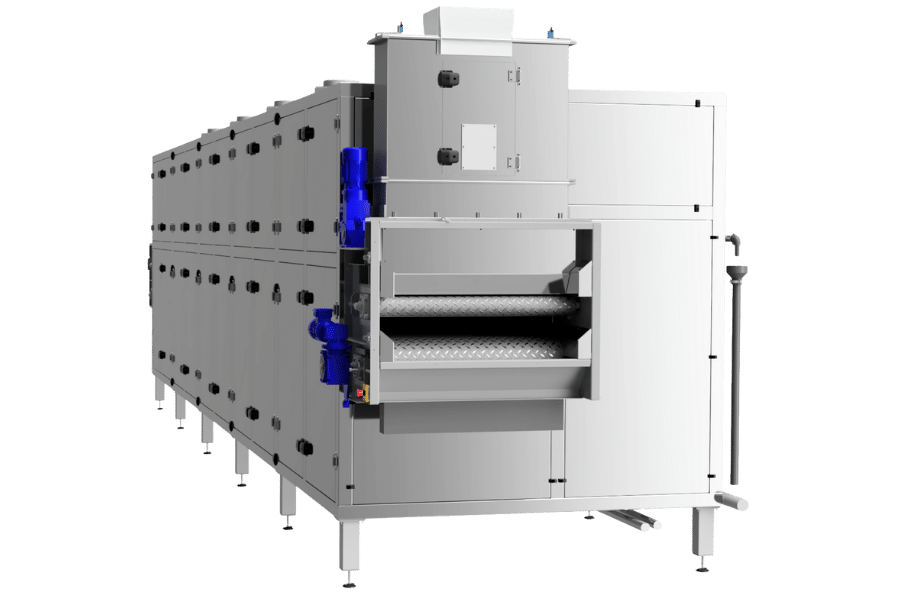

With the heat pump drying systems from HARTER, you can reliably and energy-efficiently dry your filter cake to the desired residual moisture content.

The result: low volume, high stability, safe handling and significant cost advantages.

How HARTER develops customized solutions for the industry is shown in How solutions for heat pump dryers are created.

A technical overview can be found in Energy-saving drying with heat pump.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Drying after chamber filter press – Functionality and advantages

After the chamber filter press, the sludge usually still contains 40 to 70% water – too much for economical further processing or disposal.

This is where HARTER heat pump drying comes in:

In the closed air circuit, the air is dried, heated and passed over the material again. This creates a constant, controlled drying process – regardless of weather or ambient air.

Your Advantages at a Glance:

- Energy savings of up to 70% compared to hot air processes

- Uniform drying at low temperatures

- Exhaust air-free process – no odor pollution

- Low operating costs and high system availability

- Exact residual moisture through intelligent control

The system is low-maintenance, clean and safe – ideal for municipal and industrial sewage sludge, chemical filter cakes, metal hydroxide sludge and other pasty materials.

You can find a practical example of efficient scaling in the article Expanding capacities with heat pump dryers.

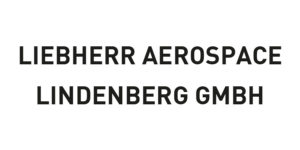

Drying systems after chamber filter presses

Drying after chamber filter press – Applications and process integration

HARTER develops solutions for a wide range of requirements in industry and disposal. Whether small batches, continuous processes or large sewage treatment plants – the system is individually designed.

Typical areas of application:

- Disposal sludge from municipal sewage treatment plants

- Chemical or metal-containing filter cakes

- Food and pharmaceutical waste

- Sludge from electroplating and surface technology

- Pigment, dye and plastic residues

The systems have a modular design and can be easily integrated into existing lines. The closed air circulation means that there are no odors or pollutant emissions. The drying temperature is between 30 °C and 75 °C, depending on the material.

HARTER offers both batch solutions and continuously operating systems. Before series production, your products are tested in the company’s own

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Drying after chamber filter press – Sustainability, safety and economy

Heat pump drying combines environmental friendliness with high efficiency. Since no exhaust air system is required, there are no energy losses or odor problems. Heat recovery within the circuit drastically reduces energy consumption.

Sustainable advantages:

- significantly lower CO₂ emissions

- no combustion or exhaust air emissions

- low-maintenance system technology

- constant process conditions

- high operational reliability

In addition to ecological advantages, the technology impresses with short amortization periods. Many HARTER systems are

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently asked questions about drying after chamber filter presses

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.