In pharmaceutical and active ingredient production, every process step counts – especially drying. Drying pharmaceuticals requires the highest purity, controlled conditions, and reproducible results. With HARTER’s heat pump drying systems, you achieve precisely this combination: precise, hygienic, and energy-efficient.

For over 30 years, HARTER has been developing customized drying solutions for sensitive products – validatable, scalable, and GMP-compliant.

This describes how these individual concepts are developed: How Solutions for Heat Pump Dryers are Developed.

For an overview of the technology, see: Energy-Saving Drying with Heat Pumps.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Drying of Pharmaceuticals – Technology and Advantages of Heat Pumps

HARTER’s heat pump drying operates with a closed, controlled air circulation system. The air is dehumidified, tempered, and recirculated over the product. This keeps the process independent of ambient air and meets the high demands of the pharmaceutical industry.

Your advantages at a glance:

- Low temperatures (20–75 °C) for gentle drying

- Energy-efficient operation through heat recovery

- Exhaust-free, hygienic system without cross-contamination

- Precise process control for reproducible results

- Validatable processes according to GMP and FDA guidelines

Due to the exhaust-free design, no germs or particles are introduced. The system operates quietly, odor-neutrally, and with low maintenance – ideal for production environments with cleanroom characteristics.

This shows how the technology can be adapted to increasing production requirements: Expanding Capacities with Heat Pump Dryers.

Drying of Pharmaceuticals

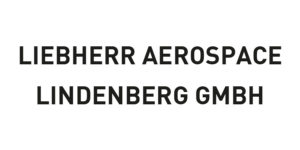

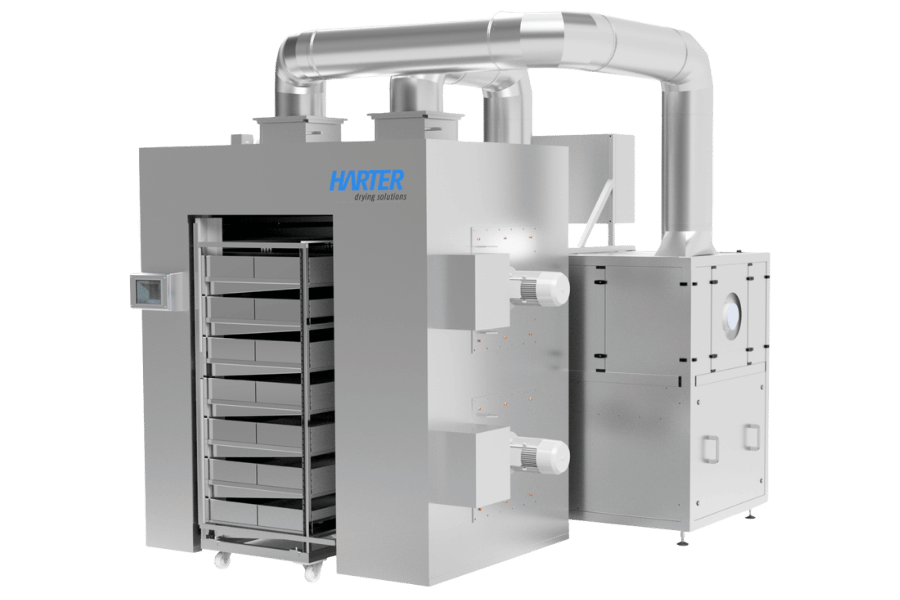

Drying of Pharmaceuticals – Applications and System Concepts

Drying pharmaceuticals involves a variety of materials – from active ingredients and intermediates to packaging components.

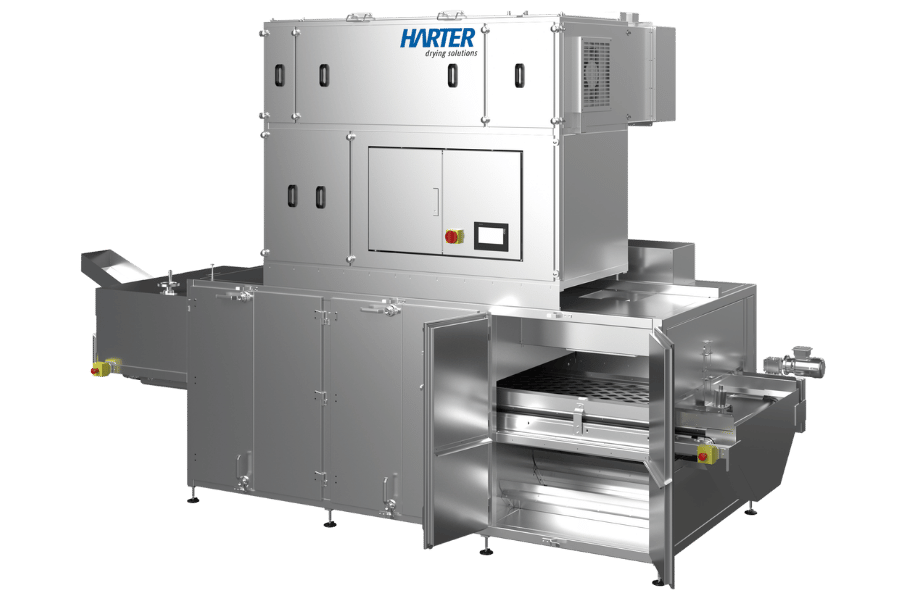

HARTER develops systems precisely tailored to these requirements.

Typical applications:

- Drying of powders, granules, and tablet blanks

- Dehumidification of capsule materials and coatings

- Stabilization of active pharmaceutical ingredients (APIs)

- Drying of pharmaceutical excipients

- Dehumidification of blisters, plastic parts, and packaging materials

System variants:

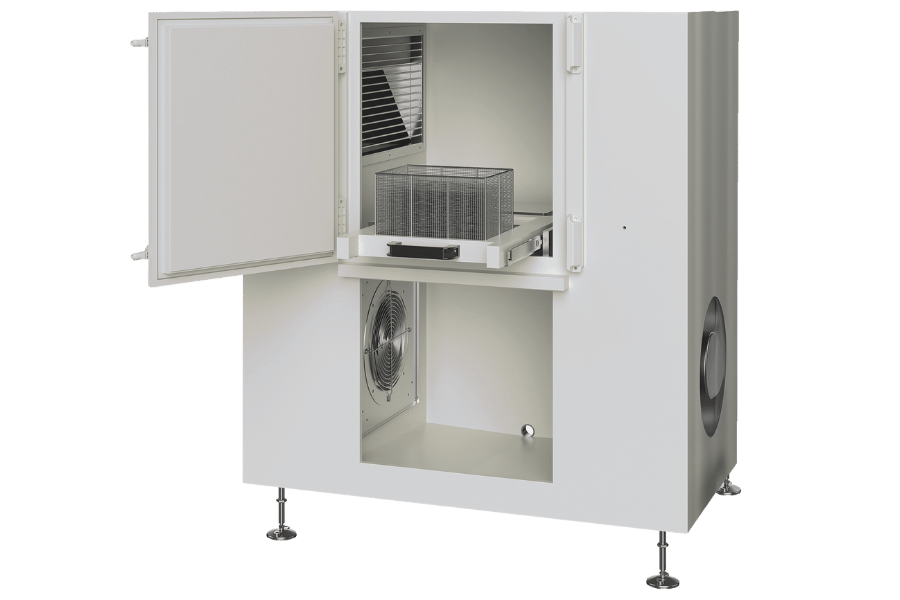

- Chamber dryers/Tray dryers for flexible batch processes

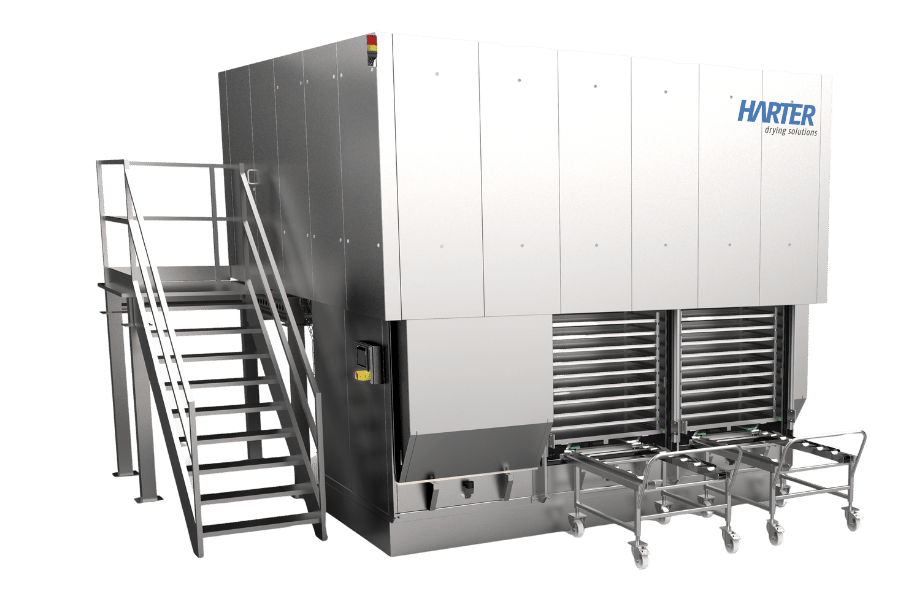

- Belt dryers for continuous production with high throughput

- Special systems for cleanrooms and GMP-compliant production areas

Before series production, HARTER tests your original products in its in-house technical center. There, parameters such as air flow, temperature, humidity, and residual water content are precisely determined. The result: validated processes with documented reproducibility and scalability.

Further pharmaceutical and industrial applications can be found under: Industries.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Drying of Pharmaceuticals – Sustainability, Safety, and Economic Efficiency

In addition to quality, sustainability plays an increasingly important role in the pharmaceutical industry. HARTER’s heat pump drying combines both: maximum process reliability with minimal energy consumption.

Sustainable advantages:

- up to 70% energy savings compared to hot air systems

- Low CO₂ emissions thanks to closed heat recovery

- No exhaust air or filter systems necessary

- Low maintenance, long service life

- Eligible technology within the framework of energy-efficient production

The systems operate independently of weather, season, or location conditions – a plus for international production sites. HARTER supports customers with integration into existing lines and with qualification according to GMP and ISO 14644.

For an insight into process development, see: How Solutions for Heat Pump Dryers are Developed.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently Asked Questions about Drying Pharmaceuticals

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.