In electroplating, drying directly determines the quality of coated parts. Water or chemical residues quickly lead to spots, corrosion, or adhesion problems. With a

Learn how HARTER develops individual solutions for industrial requirements here: How solutions for heat pump dryers are created.

An overview of the technology is provided by: Energy-saving drying with a heat pump.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

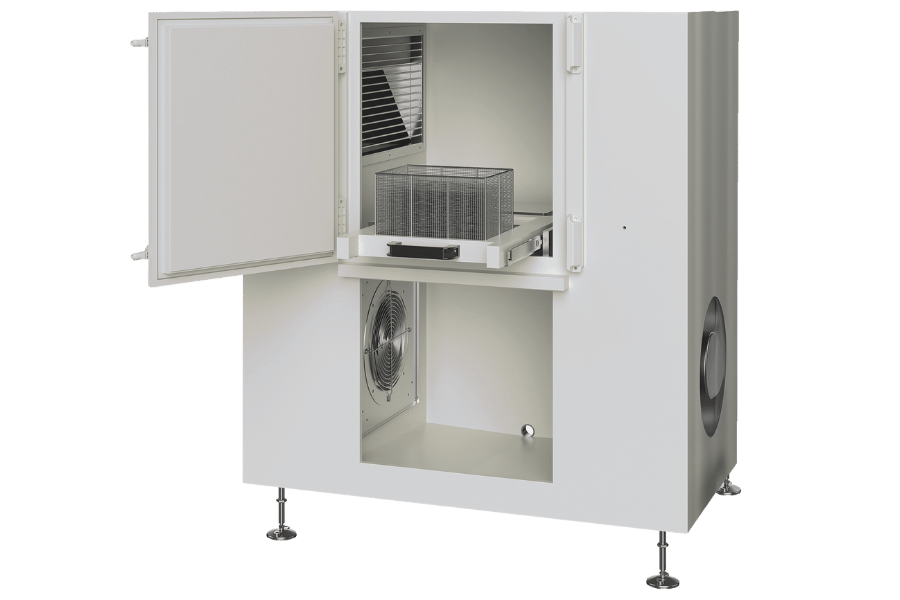

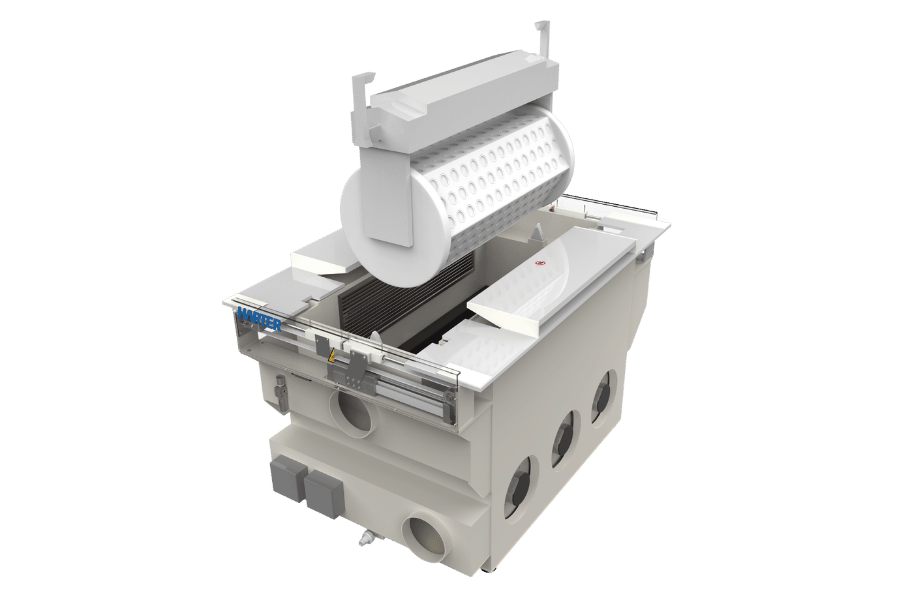

Drying Oven for Electroplating – Functional Principle and Technology

After galvanic coatings – such as nickel, zinc, chrome, or anodizing – components must be reliably dried. The rule is: no drops, no residues, no surface alteration. The HARTER drying oven operates with dehumidified, tempered air that circulates in a closed loop.

The process air is dried via a heat pump and then brought back to the optimal temperature.

This creates a uniform, gentle drying process that protects even sensitive surfaces – without spots or edge marks.

Advantages of the Technology:

- no exhaust air, no external air influences

- stable, reproducible process conditions

- low temperatures between 30 °C and 75 °C

- up to 70% less energy consumption than hot air systems

- short drying times with maximum quality

The article provides insights into efficiency and scalability: Expanding capacities with heat pump dryers.

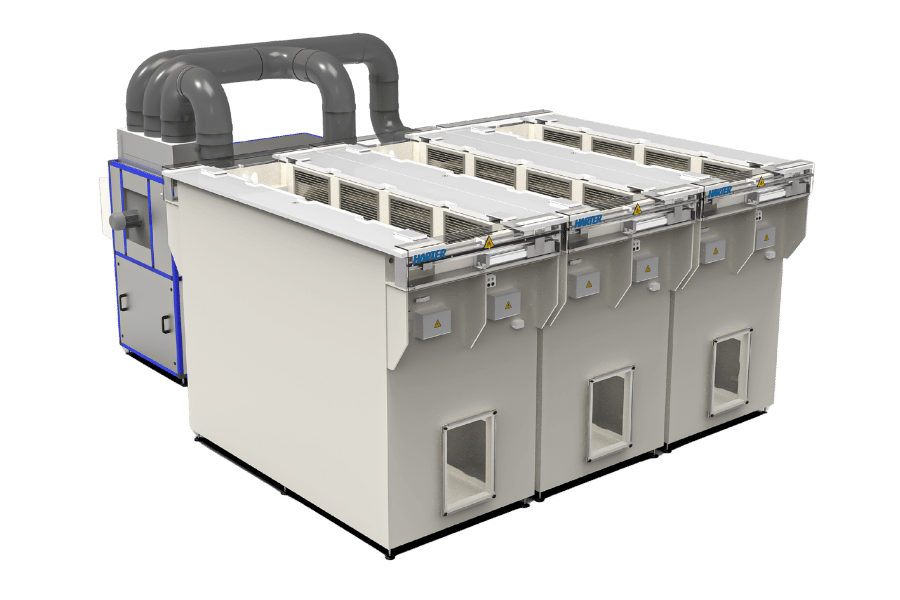

Drying Oven for Electroplating

Drying Oven for Electroplating – Applications, Designs, and Integration

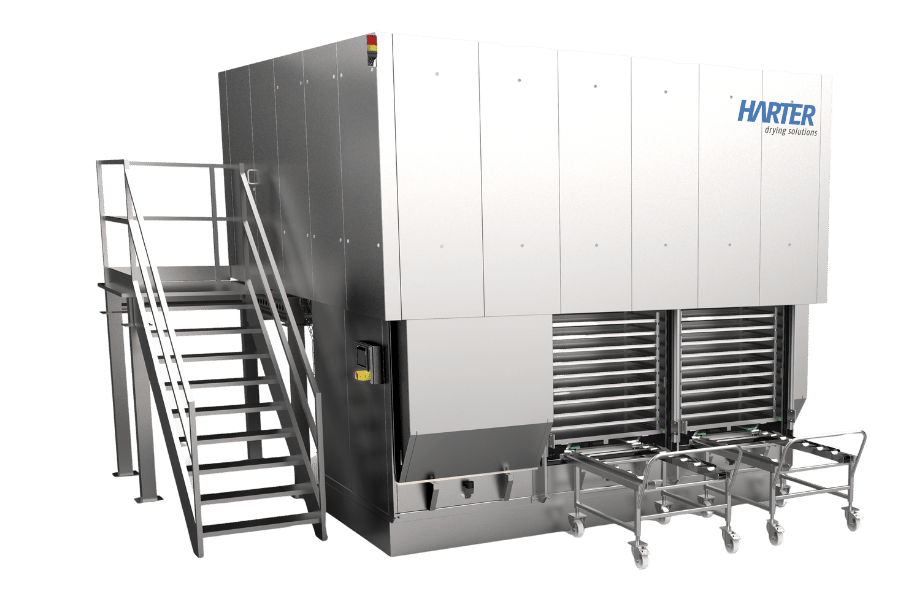

HARTER systems are designed for a wide range of production environments – from small batches to fully automated lines.

The systems can be flexibly adapted to workpiece size, geometry, and throughput.

Typical applications:

- Drying of galvanized or anodized metal parts

- Surfaces with high optical requirements (e.g., chrome, brass, die-cast zinc)

- Plastic coatings or hybrid components

- Cleaning and dehumidification after chemical pre-treatment

Designs and Options:

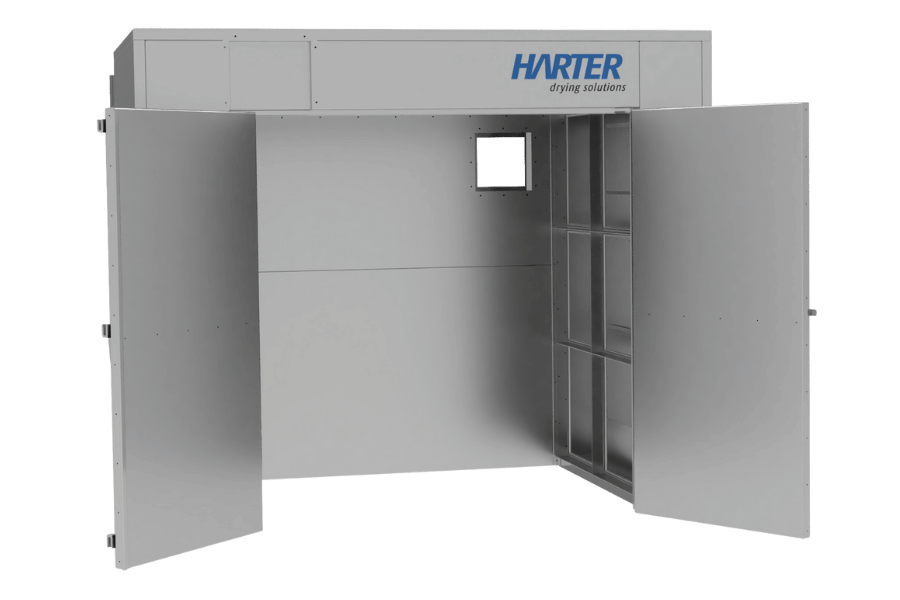

- Batch ovens (chamber or tray dryers): ideal for varying workpieces or small series

- Continuous and tunnel dryers: for automated electroplating lines with constant throughput

- Special solutions: Integration into existing systems, special air guidance systems, stainless steel design for cleanroom requirements

Each system is individually designed – from air guidance and air volume to temperature distribution.

The result: a reproducible, validated process without spot formation or distortion.

In its in-house technical center, HARTER tests your original parts under realistic conditions. Parameters such as air velocity, temperature, and humidity are precisely set – forming the basis for precise series design.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Drying Oven for Electroplating – Quality, Sustainability, and Economic Efficiency

Heat pump drying is not only efficient but also sustainable. Thanks to the closed air circuit, there is no need for fresh or exhaust air systems. Waste heat is fully recovered – significantly reducing energy consumption and CO₂ emissions.

Your advantages at a glance:

- stable coating quality through controlled drying

- no spot formation, no water stains or tarnishing

- Energy savings of up to 70%

- hygienic, exhaust-free system

- durable, low-maintenance technology

Furthermore, HARTER enables the integration of modern energy and environmental management systems, such as ISO 50001. Many systems are

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently Asked Questions about Drying Ovens for Electroplating

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.