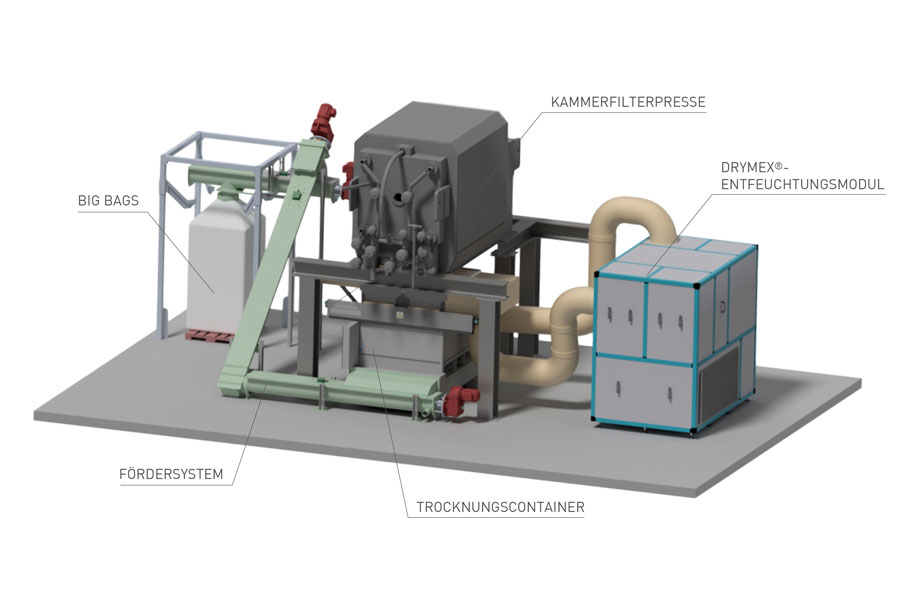

There are certain drying applications where the question arises how to ideally remove the dried sludge from the drying station and prepare it for transport. Harter offers a new comprehensive solution for such applications as follows. The drying container is installed below the chamber filter press. Following pressing, the sludge is emptied into this container. Subsequently, the sludge is dried in a closed air system to obtain a dry matter content of between 80 and 90 percent. In this process, weight and volume are reduced by as much as 60 percent depending on the type of sludge being dried. A Drymex® dehumidification module is required to provide the air required for the process. Then, a screw conveyor transports the dried sludge to the station where it is filled in big bags. The whole process is fully automated. This is a dust-free and absolutely clean solution.