As a leading industrial dryer manufacturer, HARTER has been developing and producing energy-efficient drying systems for a wide range of industries for over 30 years. Whether it’s food, chemicals, pharmaceuticals, surface treatment or environmental technology – each system is precisely tailored to the product, process and environment.

The heat pump drying from HARTER combines maximum energy efficiency with reproducible quality – a technology that sets standards.

How individual solutions arise from requirements is shown in: How solutions for heat pump dryers are created.

A technical overview is provided by: Energy-saving drying with heat pump.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

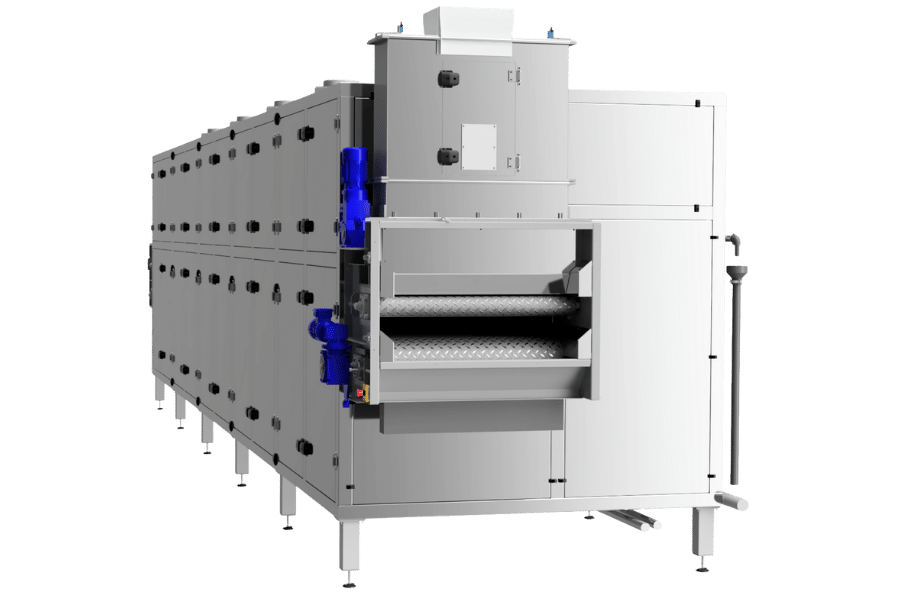

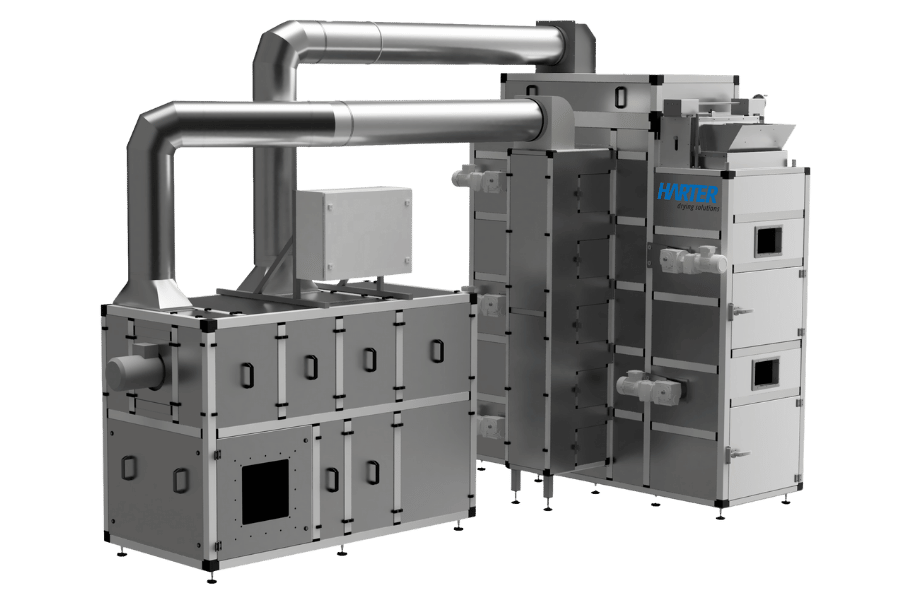

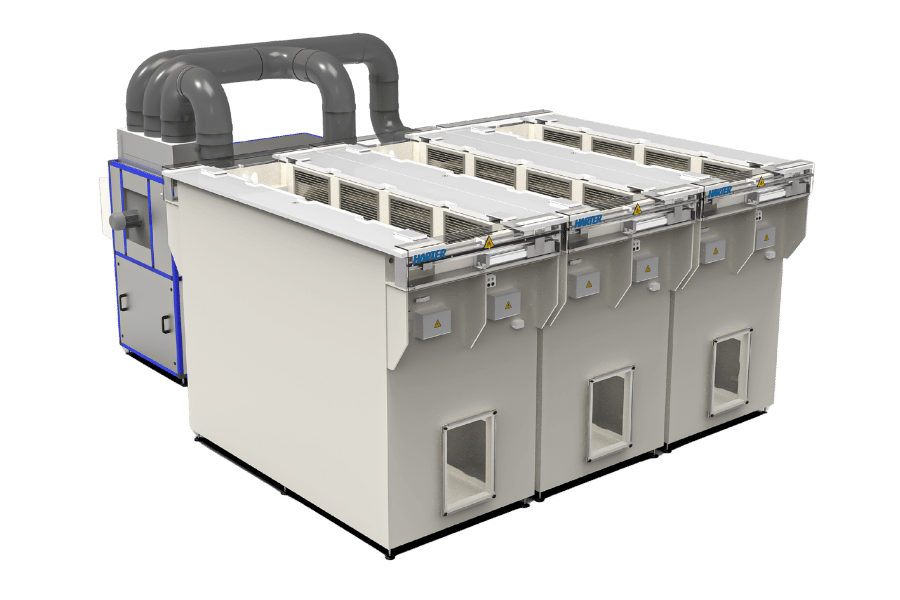

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Industrial dryer manufacturer – Technology with a system

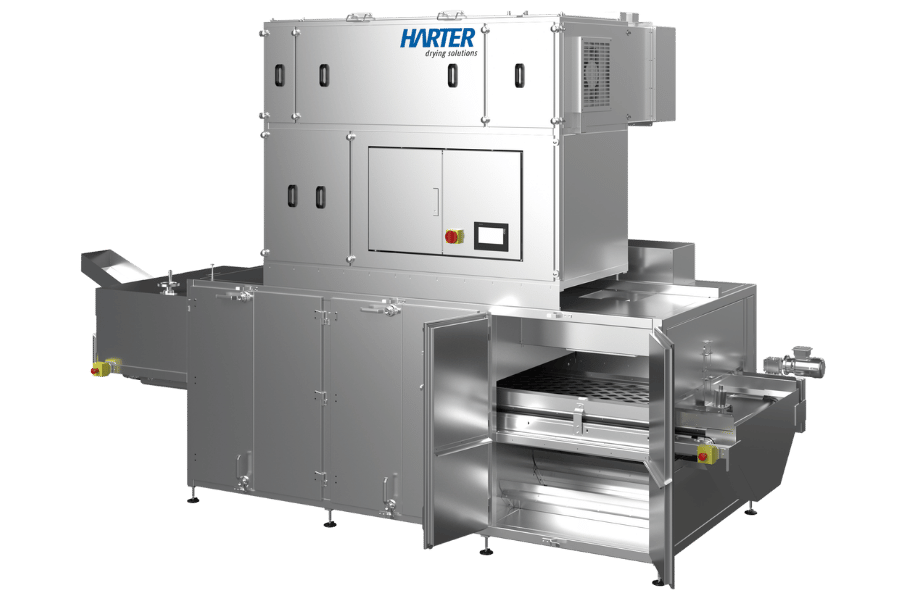

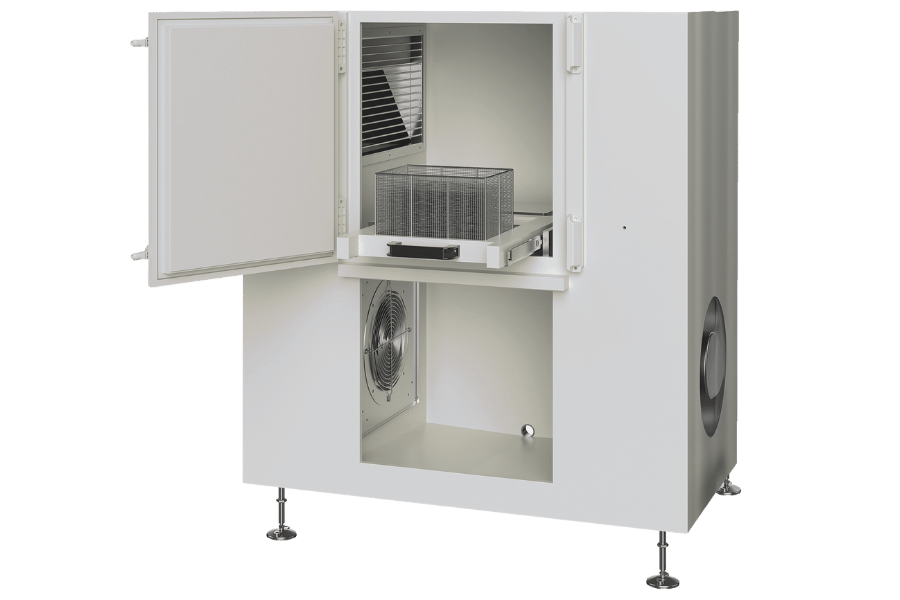

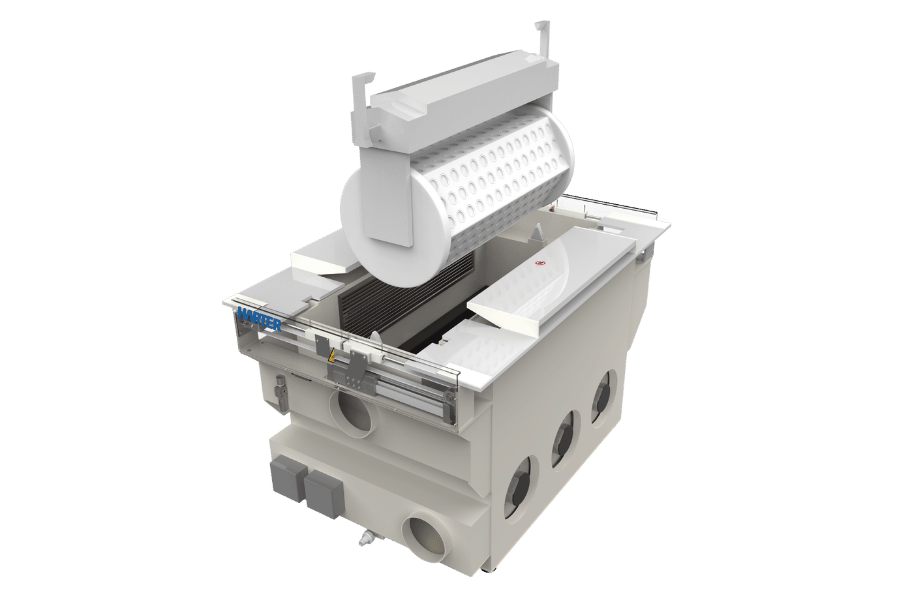

HARTER has brought heat pump drying to industrial perfection. The closed air circuit principle ensures that the process air remains in the system, is dehumidified and reused – without exhaust air losses and without influence from outside air.

Advantages of this technology:

- up to 70% less energy consumption compared to conventional hot air drying

- precise temperature control between 20 °C and 75 °C

- uniform residual moisture levels for all product types

- exhaust air-free, clean operation without dust or odors

- long service life thanks to high-quality materials and robust technology

Heat pump drying is suitable for almost all industrial processes – from batch drying to continuous line integration.

How companies are expanding their production capacities with this technology is shown in Expanding capacities with heat pump dryers.

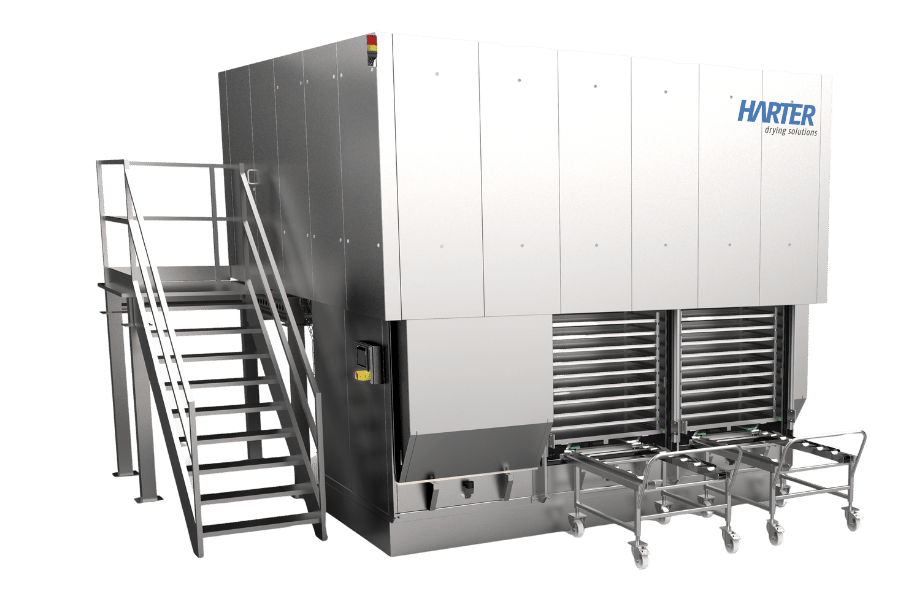

Industrial dryers

Industrial dryer manufacturer – Industries, applications and system concepts

As a manufacturer, HARTER covers a broad range of applications. Each industry has its own requirements – HARTER delivers the right solution.

Typical applications:

- Food industry: Drying of fruit, vegetables, herbs, meat or pet food

- Chemicals & Pharma: controlled residual moisture levels for powders, granules or tablets

- Metal processing: Drying after cleaning, coating or electroplating

- Plastics technology: Dehumidification of molded parts and components

- Environmental technology: Sewage and industrial sludge after chamber filter press

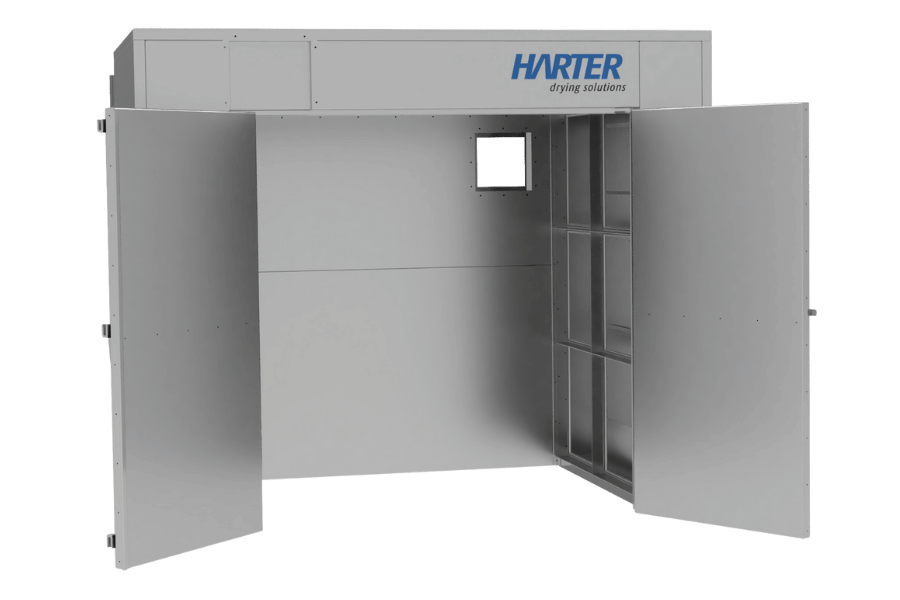

System types:

- Chamber dryers/tray dryers for flexible batch processes

- Belt and tunnel dryers for continuous production processes

- Special systems for individual space, volume or material requirements

All systems are tested in the company’s own technical center. Here, HARTER tests the products of its customers – sectional image, air flow, temperature and humidity are precisely determined. These data flow directly into the series design and guarantee maximum process reliability.

Further examples and fields of application can be found in the Industries section.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Industrial dryer manufacturer – Sustainability, energy efficiency and future viability

Heat pump drying stands for ecological responsibility and economic efficiency at the same time. Thanks to the closed air circuit, energy is used multiple times; waste heat remains in the system. This significantly reduces operating costs and reduces CO₂ emissions.

Sustainable advantages of HARTER technology:

- up to 70% energy savings

- no exhaust air emissions or filter costs

- reduced CO₂ balance

- long service life thanks to robust components

- eligible technology (e.g. BAFA, EU programs)

Many customers combine HARTER dryers with photovoltaics, heat recovery or energy monitoring systems. This makes production not only more efficient, but also more sustainable.

How companies optimize their processes with HARTER is described in: How solutions for heat pump dryers are created.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently asked questions to HARTER

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.