Die Industrietrocknung bei niedrigen Temperaturen ist die Antwort auf steigende Anforderungen an Energieeffizienz, Produktqualität und Prozesssicherheit.

Mit der Wärmepumpentechnologie von HARTER trocknen Sie Materialien jeder Art schonend, reproduzierbar und wirtschaftlich – unabhängig von Wetter oder Umgebungsluft.

HARTER entwickelt und fertigt komplette Trocknungssysteme „Made in Germany“ – von der Analyse im eigenen Technikum bis zur individuellen Serienanlage.

Wie aus Ideen konkrete Lösungen entstehen, zeigt So entstehen Lösungen für Wärmepumpentrockner.

Ein technischer Überblick findet sich im Beitrag Energiesparende Trocknung mit Wärmepumpe.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

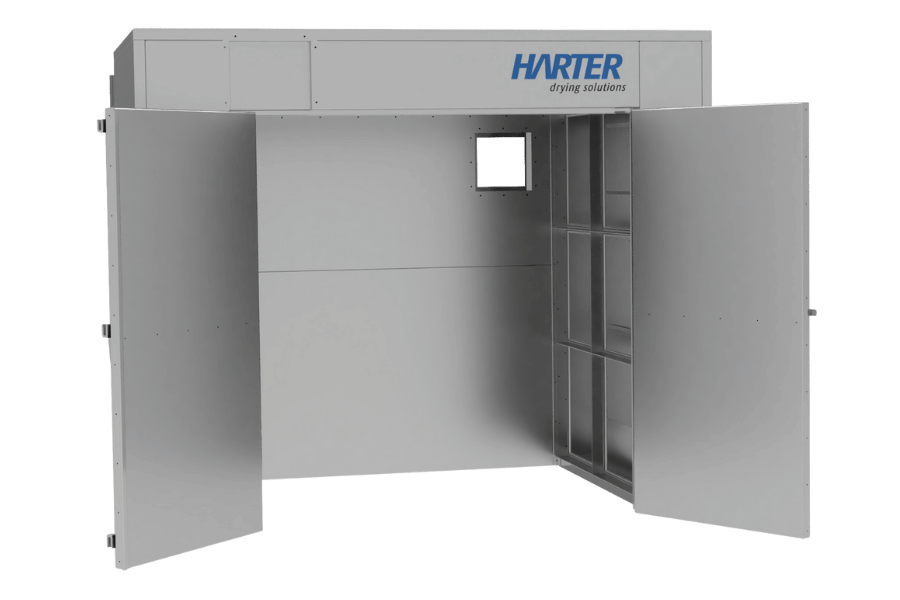

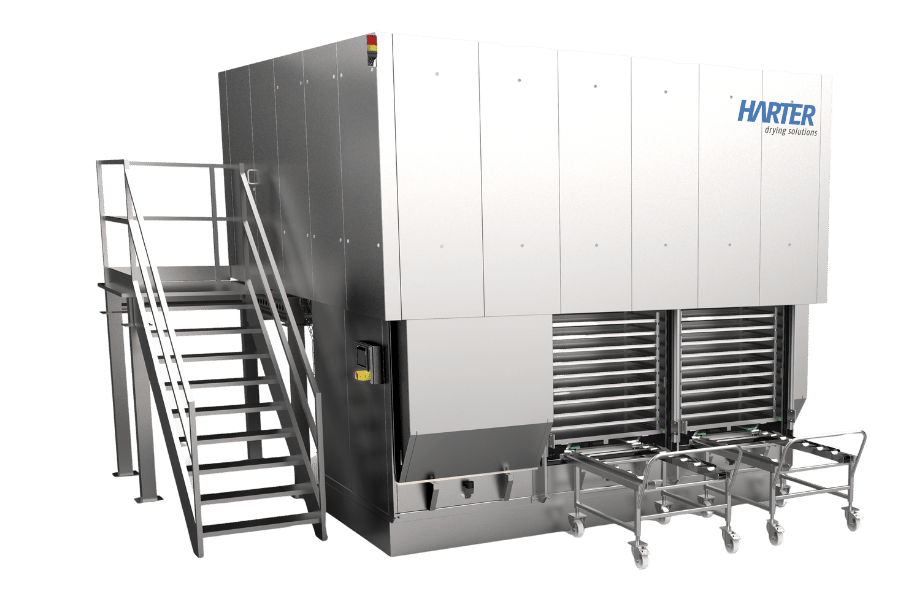

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Industrial drying at low temperatures – functional principle and advantages

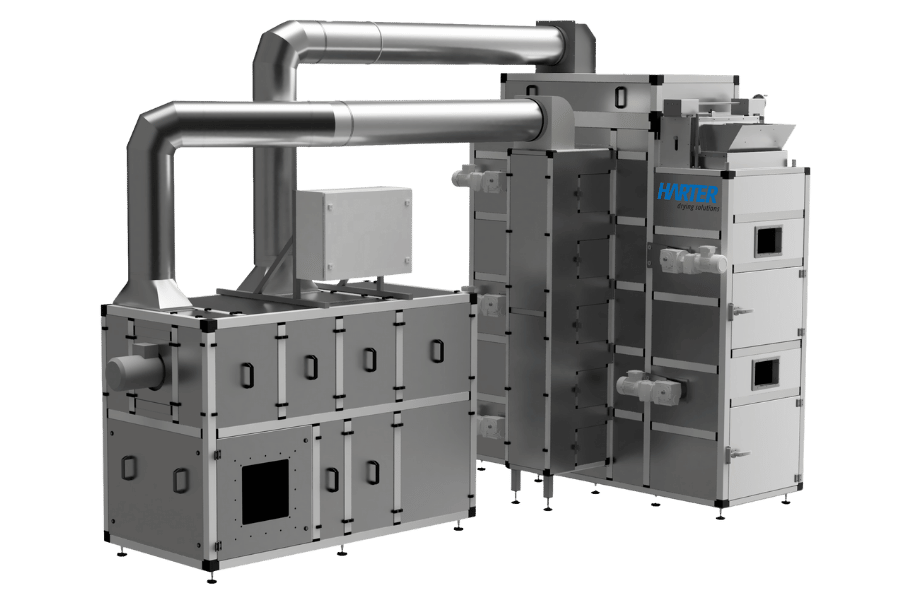

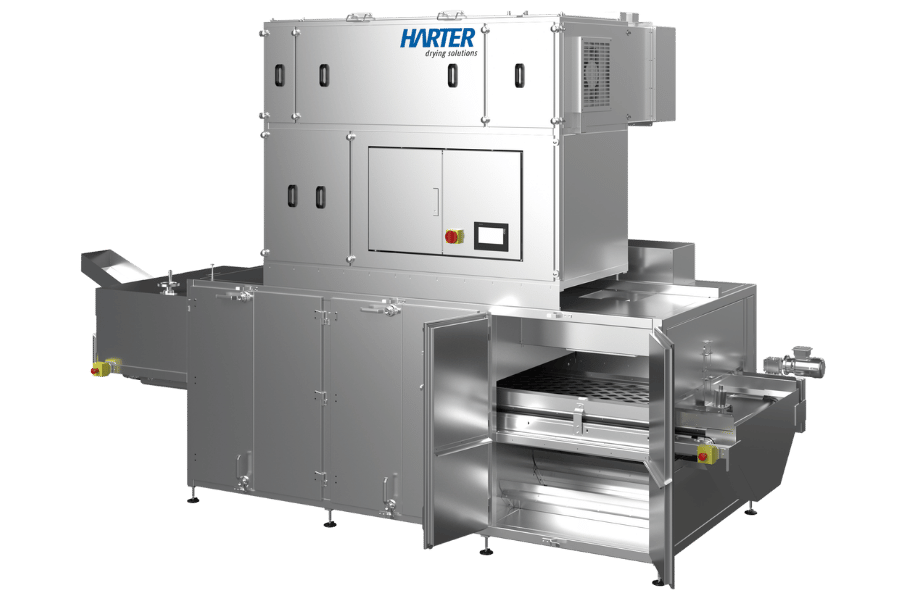

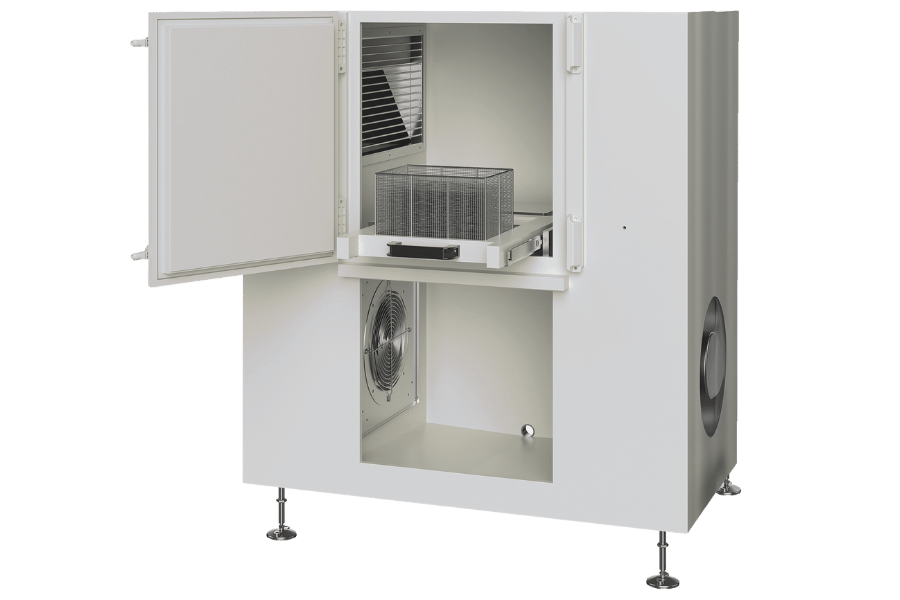

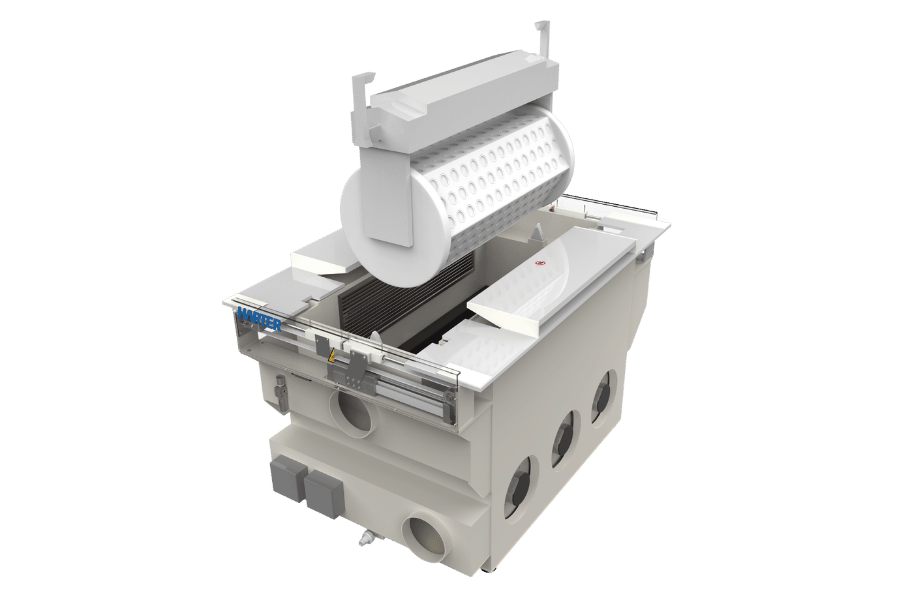

The core principle of HARTER technology is the closed air circuit with integrated heat pump. The process air is dehumidified, tempered, and reused – a circuit without external or exhaust air. This keeps the drying process independent of the outside air and constantly controllable.

Advantages at a glance:

- uniform results at temperatures from 20 °C to 75 °C

- up to 70% less energy consumption compared to hot air systems

- no dust or germ entry due to exhaust air-free design

- stable processes for sensitive materials

The systems can be precisely controlled – temperature, air volume, humidity, and drying time remain constant throughout the entire process.

This ensures consistent product quality with minimal energy consumption.

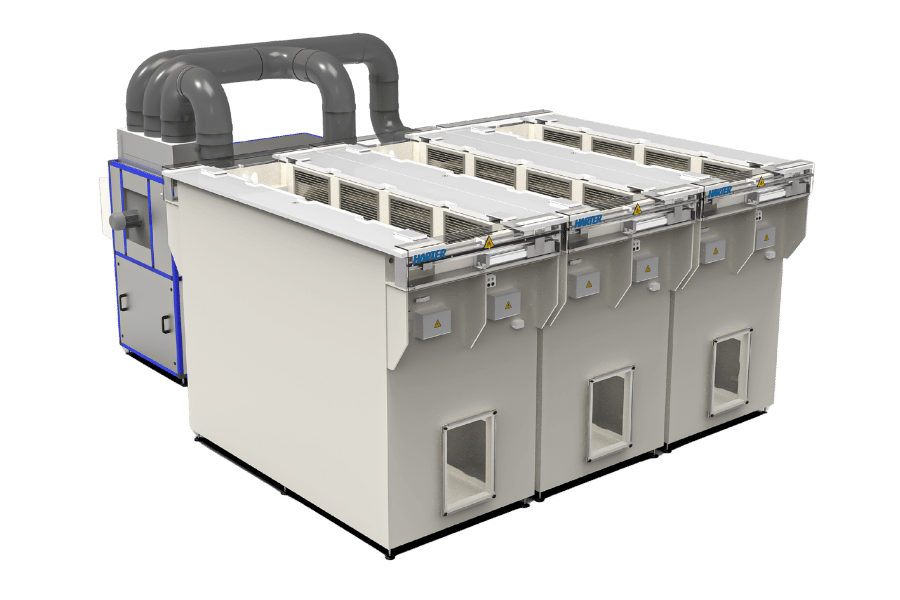

How HARTER efficiently expands production capacities through modular solutions is described in the article Expanding capacities with heat pump dryers.

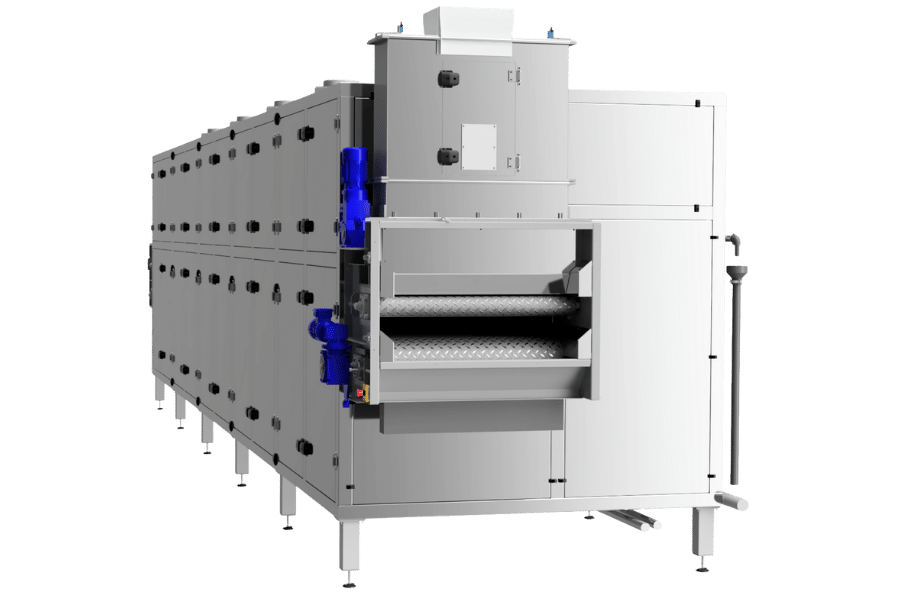

Drying systems for industry

Industrial drying at low temperatures – applications and system diversity

HARTER’s technology is versatile and suitable for almost all industrial sectors:

- Food and feed: Gentle drying of sensitive products, preservation of color and aroma

- Chemicals and pharmaceuticals: Precise residual moisture levels, validatable processes

- Metal and plastic parts: Fast, spot-free drying after cleaning or coating

- Surface technology: Electroplating and paint drying without heat distortion

- Sewage and industrial sludge: Reduction of volume and disposal costs

Each system is precisely tailored to the product, volume, and line layout. Whether batch or continuous drying – HARTER delivers customized systems that can be integrated into existing processes.

Original products are tested in advance in the company’s own technical center. Airflow, temperature, and humidity are specifically determined to define the optimal process window. This guarantees reliable results for testing, validation, and series production.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Industrial drying at low temperatures – sustainability and future security

The combination of heat pump, closed air circulation, and heat recovery makes HARTER systems particularly efficient.

Energy consumption is significantly reduced, and waste heat is fully utilized – a real contribution to climate protection.

Sustainable advantages:

- up to 70% energy savings

- significantly lower CO₂ emissions

- reproducible quality without energy waste

- low-maintenance, durable technology

Thanks to their modular design, the systems can be adapted to changing production volumes. They can also be combined with photovoltaic or heat recovery systems. Many HARTER solutions meet the requirements for energy efficiency and environmental support programs.

An overview of the different industry solutions can be found at: Industries.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently Asked Questions about Industrial Drying at Low Temperatures

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.