A manufacturer of retaining elements was looking for a dryer to meet the requirements posed by their very widespread part portfolio. They chose a heat pump based condensation system for in-barrel drying of their bulk items.

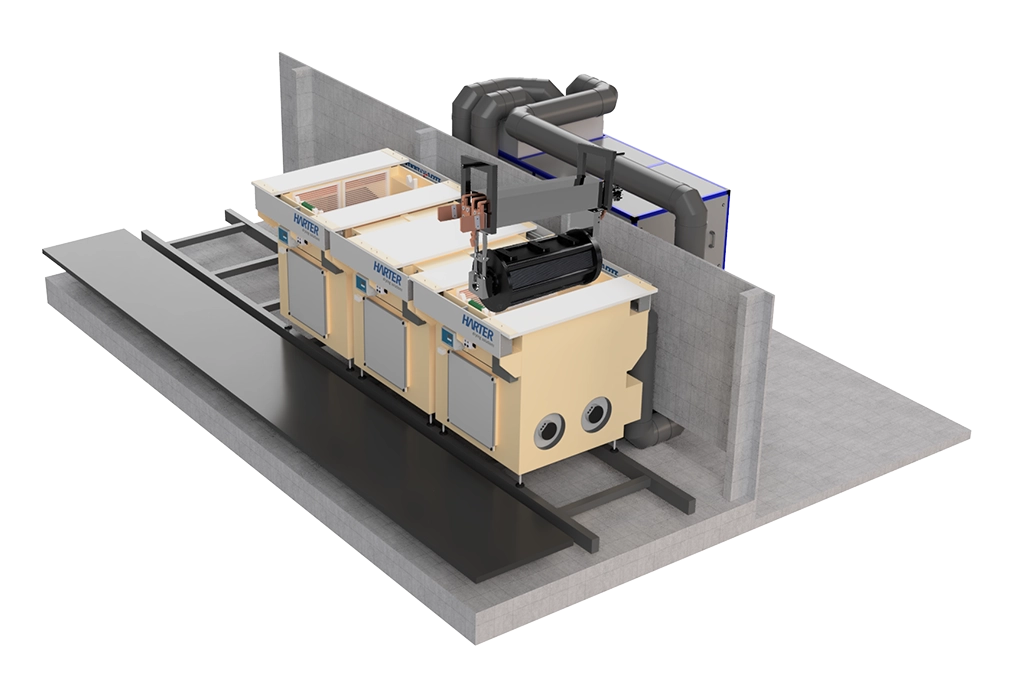

The heat pump based condensation drying technique developed by drying system manufacturer Harter proved to be the solution of choice to replace the obsolete dryer of the retaining element specialist by state-of-the-art technology. The projects started with drying tests in Harter’s in-house test center. The tests established the parameters to ensure successful drying, namely time, temperature, air humidity, air flow rate, air speed, and air routeing.

Read the complete report here.