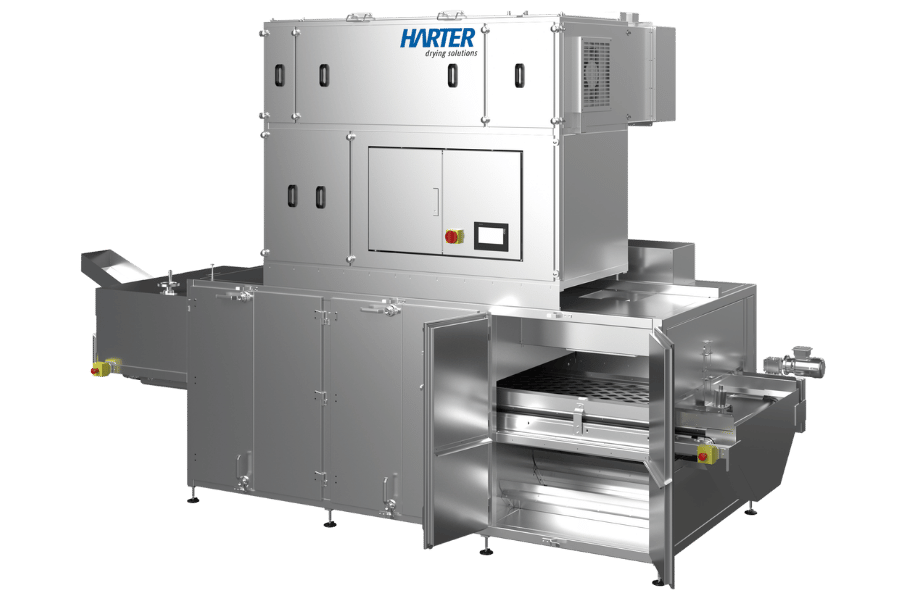

The disposal of sewage sludge is one of the biggest challenges in municipal and industrial wastewater treatment. With a HARTER sewage sludge drying system, you significantly reduce sludge volume, lower transport and disposal costs, and simultaneously meet environmental regulations.

The innovative heat pump drying operates exhaust-free, hygienically, and extremely energy-efficiently – ideal for municipal wastewater treatment plants, industrial, and chemical facilities.

How HARTER develops individual solutions for every requirement is shown in: How Solutions for Heat Pump Dryers are Created.

An overview of the technology can be found in: Energy-Saving Drying with Heat Pumps.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

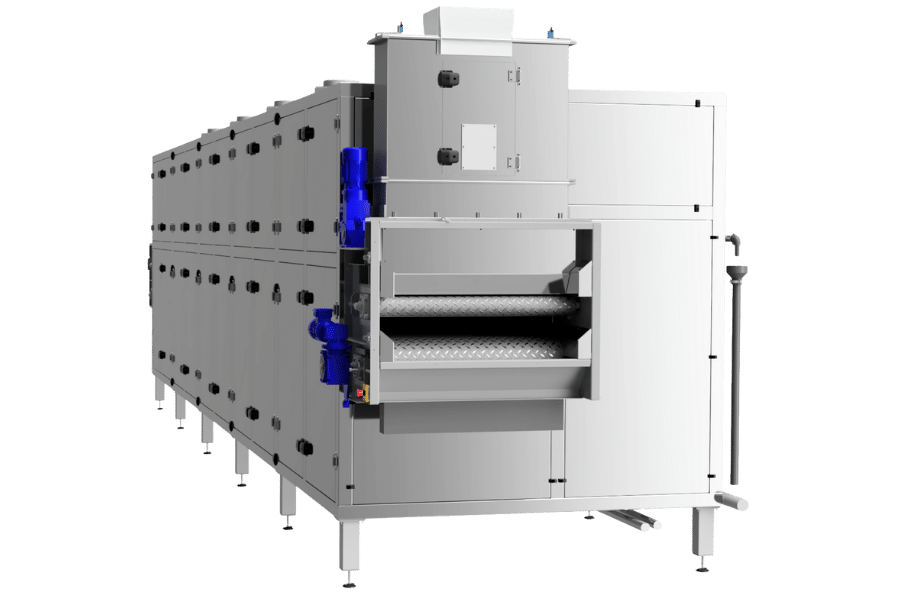

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Sewage Sludge Drying System – Operating Principle and Process Advantages

After mechanical dewatering, sewage sludge often still contains 60–80% water. Only through targeted thermal drying does the sludge become transportable, storage-stable, and significantly easier to dispose of or thermally recover.

The HARTER heat pump drying operates in a closed air circuit:

The air is dehumidified, heated, and recirculated over the material – completely without exhaust air losses. The system reuses the energy recovered in the heat pump multiple times, drastically reducing electricity consumption.

Your advantages at a glance:

- Up to 70% less energy consumption than with hot air processes

- Exhaust-free, low-odor operation

- Uniform residual moisture levels at low temperatures (30–75 °C)

- low-maintenance, durable technology

- Stable process control independent of ambient air

How HARTER modularly expands systems and designs them for higher throughputs is shown in: Expanding Capacities with Heat Pump Dryers.

Sewage Sludge Drying Systems

Sewage Sludge Drying System – Applications, Designs, and Integration

The HARTER sewage sludge drying systems are suitable for both municipal and industrial applications. Whether for municipal wastewater treatment plants, chemical plants, paper mills, or electroplating facilities – HARTER delivers customized systems for every requirement.

Typical Application Areas:

- Municipal and industrial wastewater treatment plants

- Sludges from the chemical, food, or pharmaceutical industries

- Electroplating and metal hydroxide sludges

- Mixed sludges from industrial processes

System Types:

- Batch and Tray Dryers for batch processes

- Belt and Tunnel Dryers for continuous throughputs

- Special Systems with customer-specific air guidance and automation

The drying temperature is precisely adapted to the material. Due to the exhaust-free design, neither odors nor pollutant emissions are generated – a major advantage for densely built-up locations or indoor operation.

In its in-house technical center, HARTER tests original sludges under real conditions. Air guidance, temperature, humidity, and residual water content are analyzed. These data form the basis for a validated, operationally reliable series system.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Sewage Sludge Drying System – Sustainability, Economic Efficiency, and Environmental Footprint

HARTER’s heat pump technology is not only efficient but also makes a significant contribution to resource conservation. Thanks to the closed air circuit and heat recovery, almost all energy remains within the system.

Sustainable advantages:

- Low CO₂ emissions due to high energy efficiency

- No combustion or exhaust air emissions

- Reduction of disposal volume by up to 70%

- Short payback periods due to low operating costs

- Eligible technology (e.g., BAFA, EU programs)

Many HARTER customers combine drying with heat recovery or photovoltaics. This further increases energy self-sufficiency and climate neutrality. Find more about related applications on Industries.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently Asked Questions about Sewage Sludge Drying Systems

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.