Conventional hot air dryers frequently do not produce the desired results. Therefore, drying often constitutes a bottleneck in the production process. And these obsolete dryers tend to be really extravagant with energy. This should be reason enough to take a closer look at an alternative drying technology which the government has classified as being eligible for subsidy.

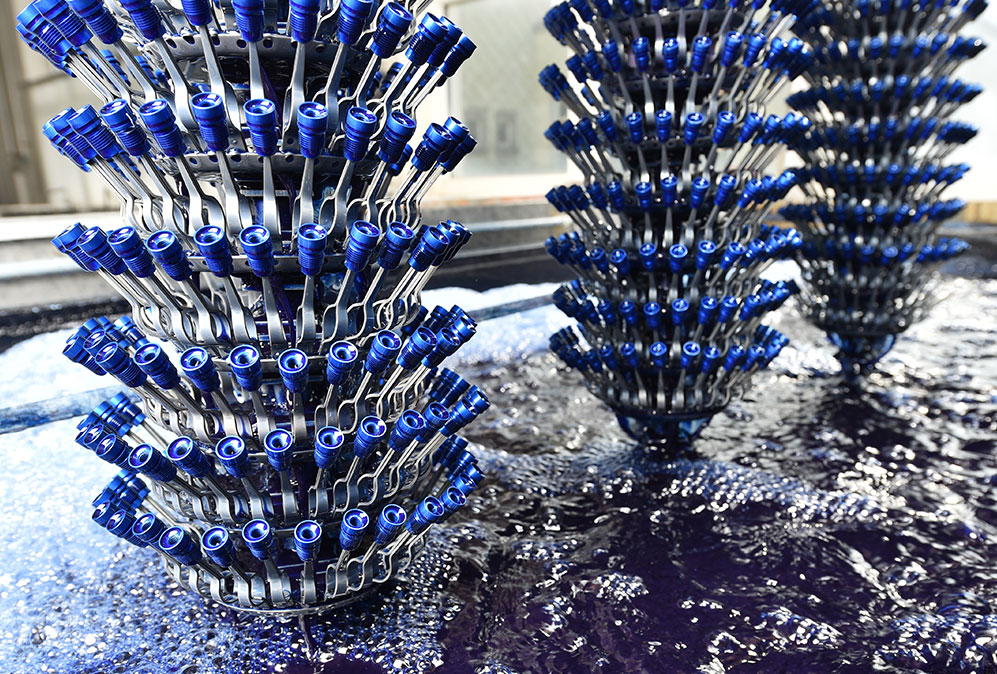

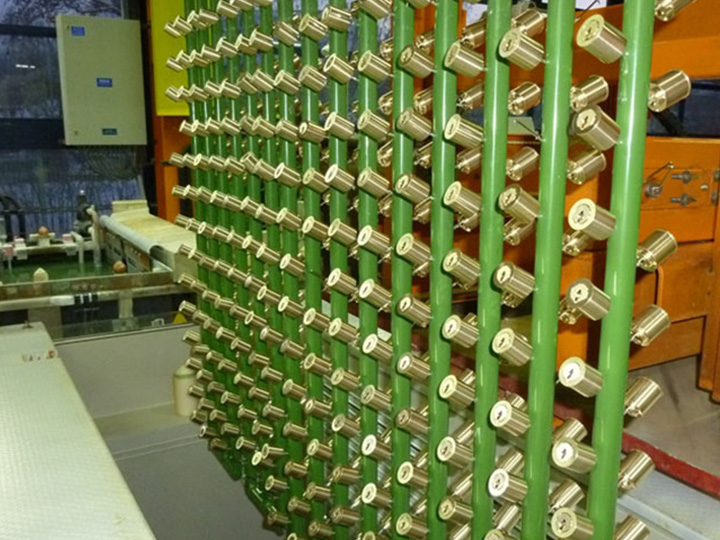

What we are talking about is heat pump based condensation drying. It was developed by drying system manufacturer Harter 30 years back. This drying process follows an alternative physical approach distinguished from conventional methods. It is capable of drying products fast, reliably and with low energy input using extremely hot air in a closed circuit to remove any moisture present. Drying is effected at temperatures variable between 20 °C and 90 °C as required for the specific product or process. The process is flexible allowing both batch operations and continuous applications. Harter offers batch dryers, such as rack dryers, and in-barrel dryers for bulk material. The portfolio also includes drying of industrial sludge resulting from wastewater treatment. Here are some examples of actual applications for illustration.

Read the complete report here (published in Werkstoffe in der Fertigung (1/2021).

Post image: © Anox