Aircraft industry projects range among our engineering gems. They are, for one, rare and, secondly, challenging in terms of developing a solution and realizing it. This is why we were very glad to receive an inquiry by a European market leader …

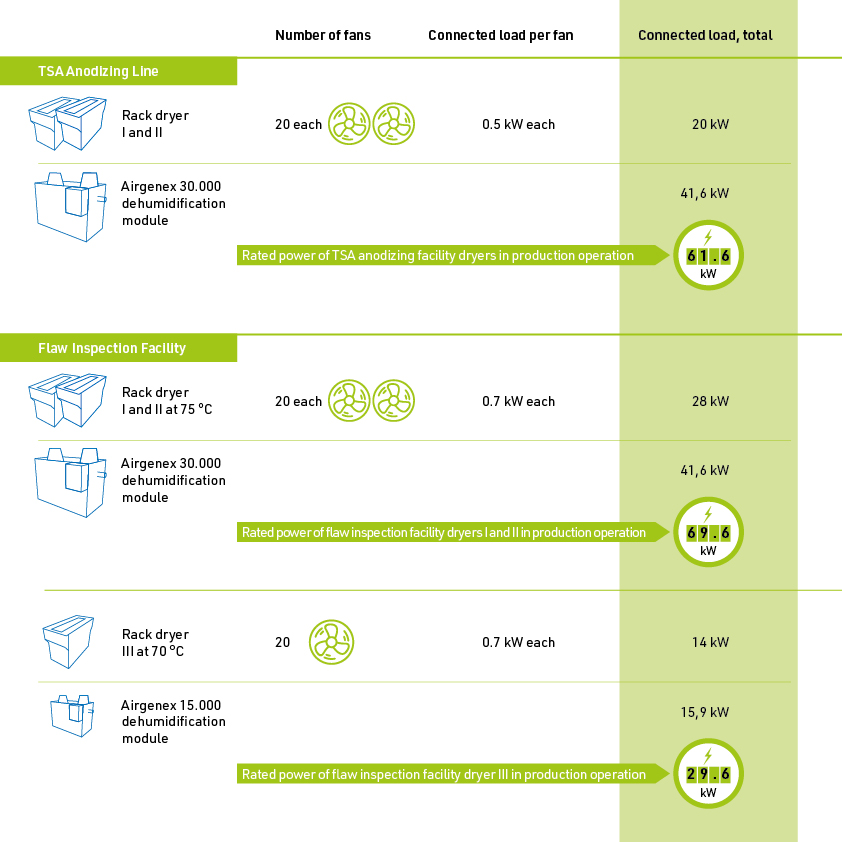

A supplier of civil and military aircraft structures invested in a new anodizing line including a flaw inspection facility to increase their capacity. Complex geometries and varying sizes of components required a special drying concept.

Large and complex components made from aluminium, titanium and CFRP are designed and manufactured in factories of a global supplier of civil and military aircraft structures. To manage an increase in capacity it was initially considered to have all components subcontract anodized and dried. Yet, there were hardly any subcontractors globally to offer such services for components as wide as six metres. So, the aircraft equipment supplier invested in a new anodizing line including a flaw inspection facility. They also needed a suitable drying concept to go with their processing line.

Drying system manufacturer Harter has developed and designed heat pump assisted condensation dryers for 30 years and installed much more than 1,000 systems in various branches of industry. Drying tests of original components in the Harter test station ultimately convinced the aircraft supplier’s project manager of the Harter drying technology.

Read the complete report here (published in JOT 61 (2021) Special Edition 3, p. 38-39. Online: https://www.springerprofessional.de/en/luftfahrt-sicherheitsfaktor-trocknung/19211822)

Post image: © Ilja MaöÌk, Fotolia