Energy Efficient Heat Pump Dryer an Ideas Provider

A gentle and likewise energy efficient drying technique has also found successful applications in the food sector in recent years. Benefits for operators of such drying systems include the retention of aromas, vitamins, and other ingredients in as well as an appealing appearance of the dried food. Government subsidy has meanwhile become available for using this heat pump based, low temperature drying technique

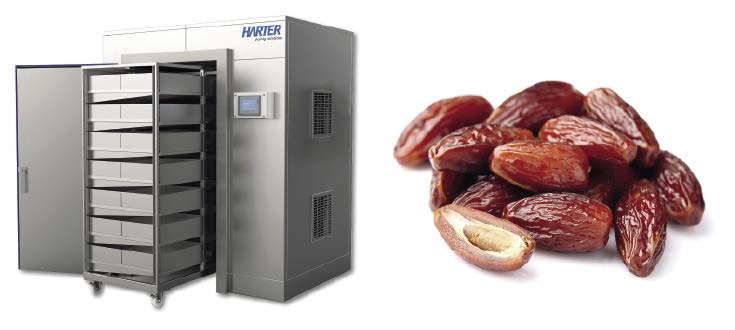

The German drying system manufacturer Harter developed the so-called heat pump based condensation drying technique more than 30 years ago and has installed more than 2,000 dryers in various industrial sectors ever since. Food producers have also discovered the benefits of such systems. Harter has successfully realised many human and pet food projects.

The big success of this low temperature drying technique is based on its physically alternative approach. Drying is accomplished using extremely dry and, thus, unsaturated air passed over or through the items to be dried. Such air perfectly absorbs any humidity present. Subsequently, the humid air is cooled – the humidity condenses to form water – reheated and returned to the drying chamber. For drying to be successful, air routeing is critical. The air must be routed precisely to obtain a good and uniform result. The drying temperature may be varied between 20 °C and 75 °C, as required for the specific product or process. If sterilisation is desired, Harter will add an optional 110 °C high temperature stage. Likewise, a cooling stage may be added if required for the specific process. The drying time depends on the residual humidity desired or required. For packaged food, where the wet package needs to be dried, drying time is often accomplished at a minute’s pace to meet the specified cycle time. For direct food drying, the drying time is often longer and as needed to obtain the desired residual humidity of the product.