The drying of dog food is a crucial factor for quality, shelf life, and taste. At the same time, it significantly influences the economic efficiency and energy efficiency of production. With the heat pump drying systems from HARTER, you are relying on a modern, sustainable technology that dries the feed gently and hygienically – with consistent product quality and minimal energy input.

You can find an initial overview of the application in the article Drying of animal feed. The article explains how customized solutions are developed from individual requirements:

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Drying dog food with a heat pump – technology and energy efficiency

Classic hot air systems consume enormous amounts of energy and often lead to uneven results. The HARTER heat pump dryers, on the other hand, work with a closed air circuit that continuously extracts moisture without losing energy or product quality.

The system guides the air over a dehumidifier, heats it via a heat pump, and directs it over the product again – exhaust air-free, clean, and constant.

This technology enables drying at low temperatures between 20 °C and 75 °C.

The advantage:

- Vitamins, proteins, and fatty acids remain stable.

- Texture and color are evenly preserved.

- The shelf life improves without additional preservatives.

The article Expanding Capacities with Heat Pump Dryers provides insights into increasing efficiency and scaling.

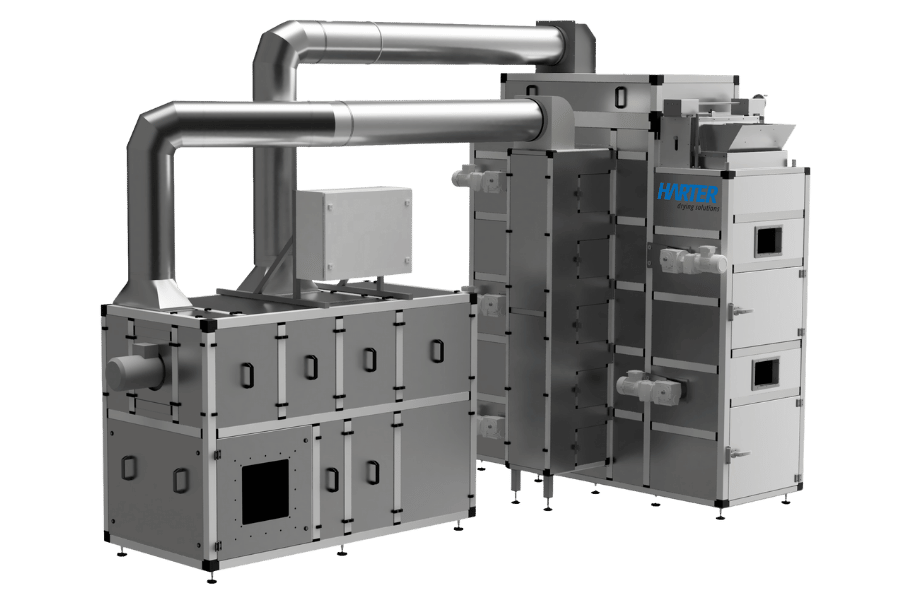

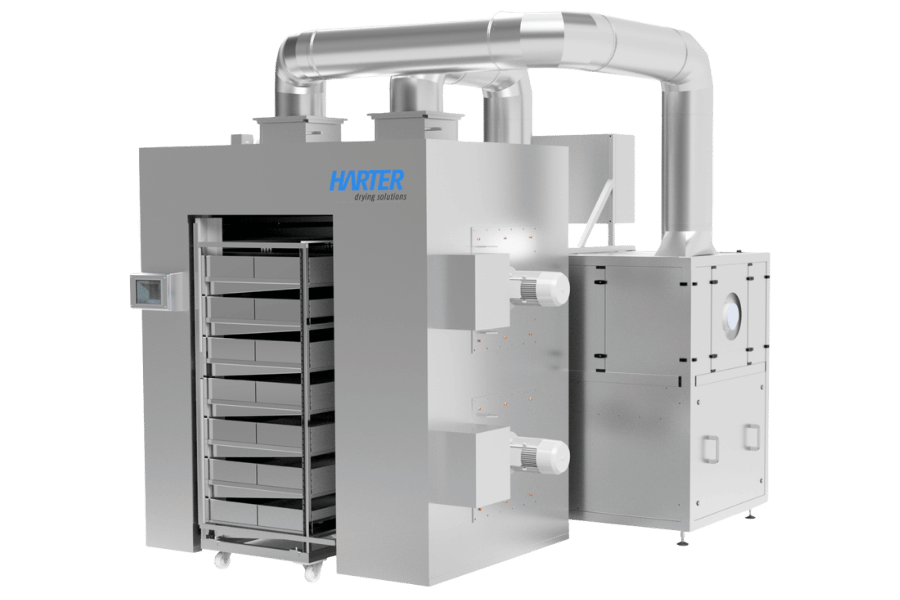

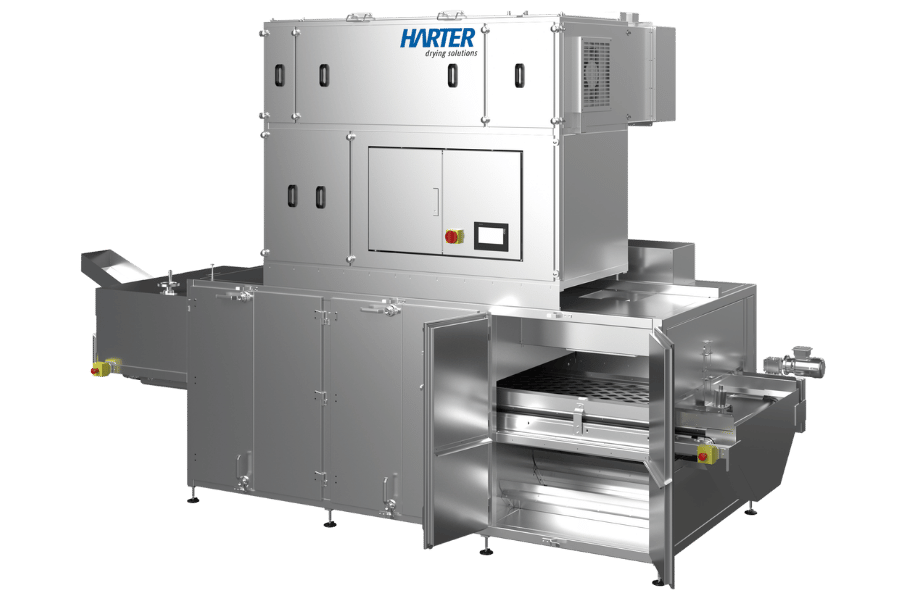

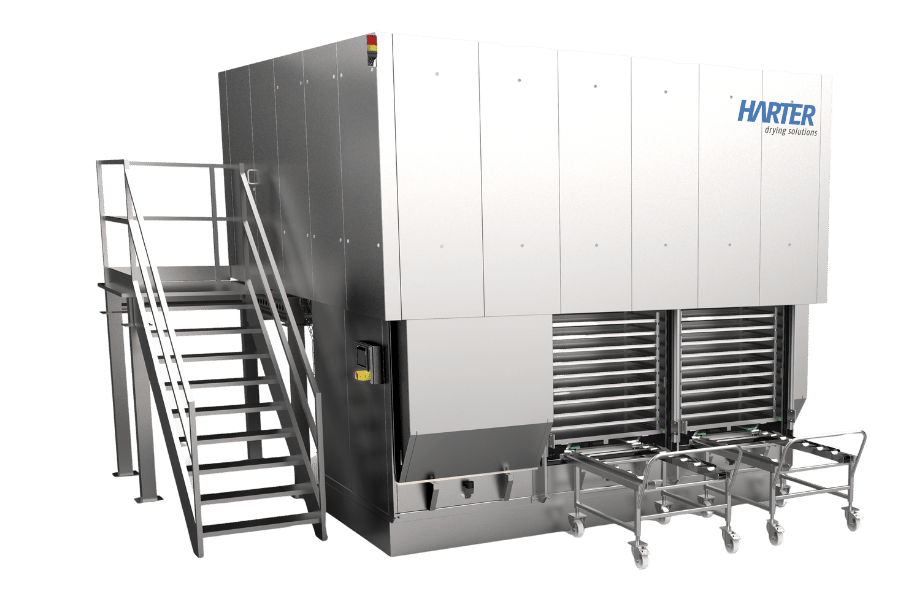

Depending on the product form, different types of systems are used:

- Tray dryer/chamber dryer for flexible batches,

- Belt dryer for continuous operation or

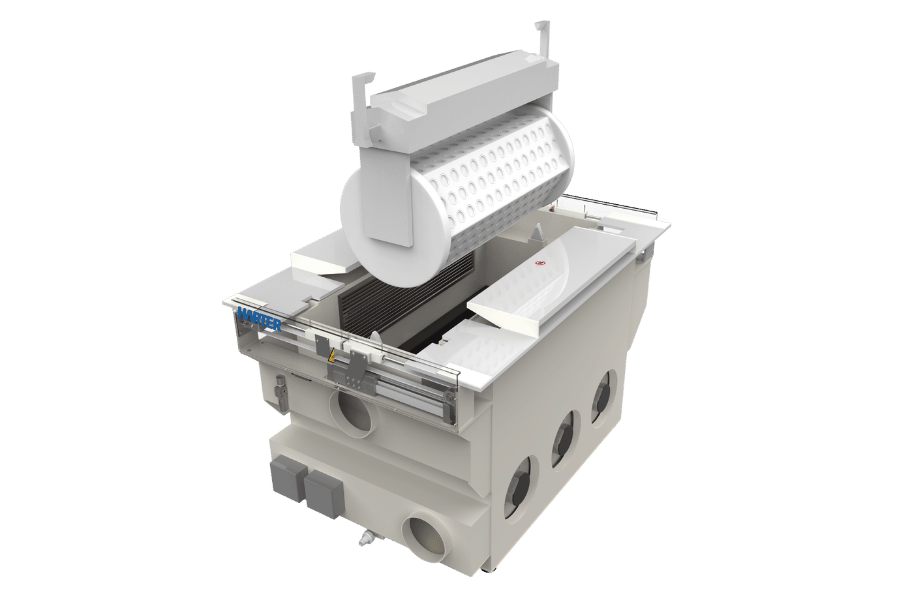

- Drum dryer for free-flowing and pelleted products.

Drying systems for dog food

Drying dog food – hygiene, quality, and process reliability

Dog food is one of the sensitive foods. Hygienic, controlled drying is therefore essential. The HARTER drying systems have been specially developed for these requirements:

- closed air circuit without external air supply,

- Stainless steel design of all air-conducting components,

- easy-to-clean construction,

- precise temperature and humidity control.

This ensures a consistent, reproducible result – regardless of external conditions. The technology protects the product from contamination and at the same time preserves aroma and structure.

The article describes practical experiences and references for animal feed drying:

Drying animal feed gently and safely.

Before series production, HARTER tests your products in its in-house technical center. Here, bulk density, air volume, temperature, and target residual moisture are precisely determined – the basis for reliable process control and consistent quality.

This results in systems that are optimally tailored to your product range, production volumes, and hygiene standards.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Drying dog food – system concepts & integration

HARTER designs each system individually: from small-scale production to large-scale production, from snacks to dry food in pellet or kibble form.

All systems are modular and can be integrated into existing lines – for example, in connection with a mixer, extruder, or packaging station. The processes can be completely automated and digitally monitored:

Temperature, humidity, and air velocity are recorded, documented, and exported for quality verification.

In the belt dryer animal feed product area, you will find suitable systems for high throughputs. Tray dryers/chamber dryers are available for variable batches, and the drum dryer pet food is ideal for pourable products such as snacks or pellets.

You can find an overview of related industrial sectors and applications on the Industries page.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently asked questions about drying dog food

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.