With rising disposal cost, drying sludge has become attractive again throughout industry.Municipalities are also looking for new ways of disposal to comply with much stricter sewage sludge disposal requirements imposed by a new regulation to become effective soon.

Drying of Sewage Sludge

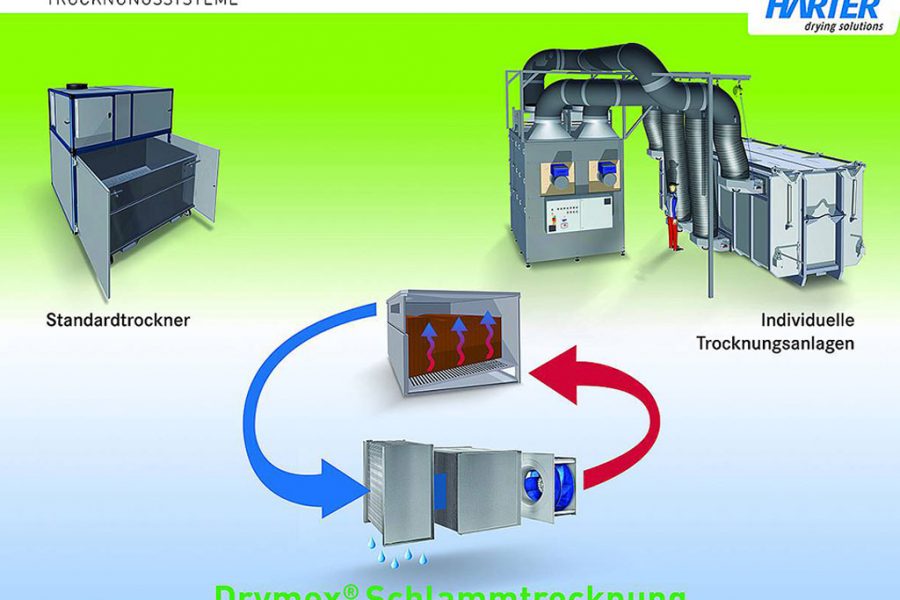

Drying system manufacturer Harter of Stiefenhofen, Germany, was established to conduct business in industrial sludge drying and has meanwhile run extensive tests on sewage sludge to be prepared for this new market. For smaller sewage plants, where decentralised sludge treatment is preferred, energy-saving heat pump based sludge drying is the ideal solution. It will also significantly reduce transport cost and help relieve traffic and environmental burdens. Dried sludge may sometimes be used for other, cost-reducing purposes.

Heat Pump Technology Eligible for Government Subsidy

Harter drying systems can be designed for either batch or continuous operation with sludge drying capacities ranging between 1 and 20 tons/day. Harter is currently looking for a municipal partner to run a pilot project for sewage sludge drying. Government subsidies may be obtained for carbon emission reduction by energy-saving Harter dryers.

Basic Information about Sludge Drying

Heat pump based condensation drying is capable of low temperature drying any aqueous sludge or substrate using extremely dry air in an energetically closed system. The method is applied to filter pressed sludge with 60 to 70 percent residual water content

_ for weight reduction by as much as 60 percent

_ for volume reduction by as much as 60 percent

_ to obtain uniformly dried sludge with a dry matter content

of 80 to 90 percent

_ using drying temperatures ranging between 40 °C and 50 °C

Economic Potential

_ Reduction of disposal cost by as much as 60 percent

_ Better waste classification may possibly be obtained.

_ Some of the material may possibly be recycled

= new income source.