A customer produces, in a continuous process, punched out parts dried at 100 °C after vibratory finishing.

Problems encountered

_ High drying temperature

_ Immediate further processing impossible

_ High energy cost

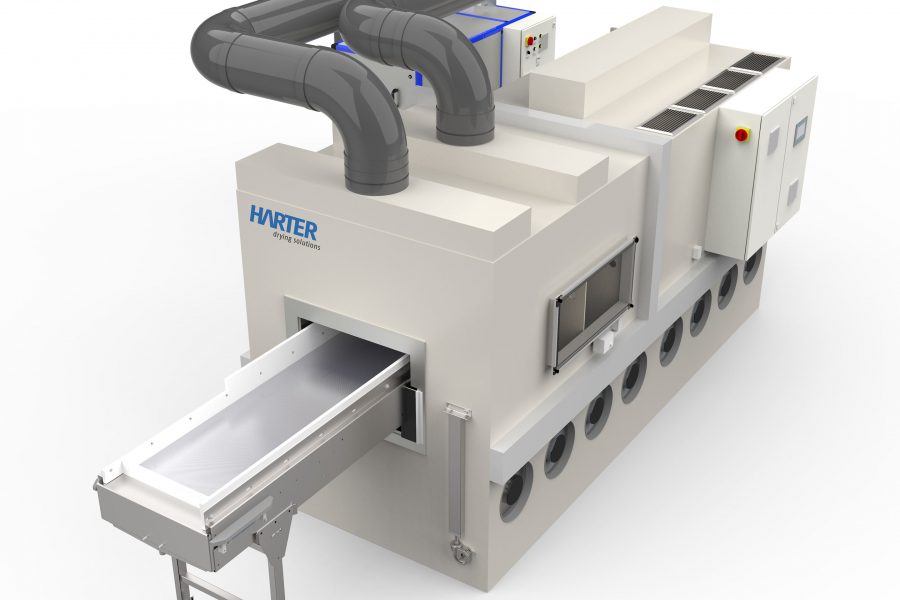

Solution – Continuous Dryer with Integrated Cooling

_ 800 kg max. of steel parts are placed on the dryer conveyor belt after cleaning.

_ Length of drying zone inside tunnel is 2 m.

_ Complete and uniform drying at 70 °C

_ Subsequent cooling to about 30 °C

_ Use of a ventilation system for cooling

_ Conveyor speed is 0.58 m/min.

_ Total drying and cooling time is 7 min.

_ Rated power of total system in production operation is about 25 kW.