Drying fruits and vegetables determines color, aroma, nutrient content, texture, and shelf life. With HARTER heat pump drying systems, you gain access to an energy-efficient, hygienic, and reproducible solution that brings your products to the desired residual moisture content at moderate temperatures within a defined time – regardless of weather and season.

Fundamentals and practical examples of the method can be found in: Energy-saving drying with heat pump.

How HARTER develops customer-specific processes is shown in: How solutions for heat pump dryers are created.

In food processing, HARTER supports you from the selection of recipes and cutting forms (slices, pieces, cubes, shavings) and process control (air volume, air guidance, temperature, humidity) to integration into existing lines. For your specific application, you receive a tailored drying concept that measurably ensures quality and sustainably reduces costs.

Do you require a custom solution and/or would you like to test the drying process beforehand?

Development with practical tests in our in-house development center

We are an innovation-driven team and welcome new challenges. HARTER tests your custom solution in the technical center under realistic conditions, optimizes the parameters, and documents the results transparently. Please contact us – we would be pleased to provide you with a non-binding consultation!

Drying systems

in over 20 countries stand for our quality

Employees

from all areas ensure a high level of vertical integration

Years of experience

in the development of innovative drying systems

Drying of Fruits & Vegetables with Heat Pump – Technology and Energy Efficiency

For drying fruits & vegetables, HARTER uses a closed air circuit with integrated dehumidification. The process air is dried, heated, and recirculated over the product. This keeps temperature and relative humidity consistently low – promoting uniform drying to the core, preserving aroma and color compounds, and reducing oxidation.

Insights into the technical implementation and energy efficiency are provided in the article: Expanding Capacities with Heat Pump Dryers.

Compared to conventional hot air drying, low-temperature drying better preserves nutritional value: vitamins, secondary plant compounds, and delicate aromas remain more stable. At the same time, energy consumption and rejects decrease because the process operates independently of ambient air and is therefore plannable.

Typical applications range from apple and banana chips, berries, stone fruit, and citrus fruits to vegetables such as tomatoes, bell peppers, onions, carrots, mushrooms, or leafy greens. Herbs and cut greens also benefit from the gentle process control – volatile aroma components are preserved, the color appears fresh, and the texture becomes crispy instead of leathery. This way, you increase the marketability in snacks, ingredient mixes, muesli toppings, or convenience products.

Drying Systems for Fruits & Vegetables

Drying of Fruits & Vegetables – Hygiene, Process Reliability, and Validation

Fruits and vegetables are microbiologically sensitive raw materials. The

How HARTER develops the optimal process control is demonstrated by: Technical Center.

Before the design, HARTER tests your original products in its own Technical Center: sectional image, bed depths, air flow (horizontal/vertical), temperature/humidity control and target residual moisture are precisely analyzed and documented. This results in a reliable database for system configuration and automation – from

A thematic overview of related industry applications can be found on the Industries page.

We dry with dry air and deliver it to the right places: A perfect interplay of air preparation and air guidance provides you with the best possible drying result.

Reliable – Competent – Long-term

Service that thinks ahead – for years to come

With the HARTER After-Sales Service, you secure a reliable and efficient drying solution for the long term. Whether it’s maintenance, spare parts supply, or technical adjustments – we support your system throughout its entire life cycle and ensure that it delivers optimal results at all times.

Drying of Fruits & Vegetables – Configuration & Integration

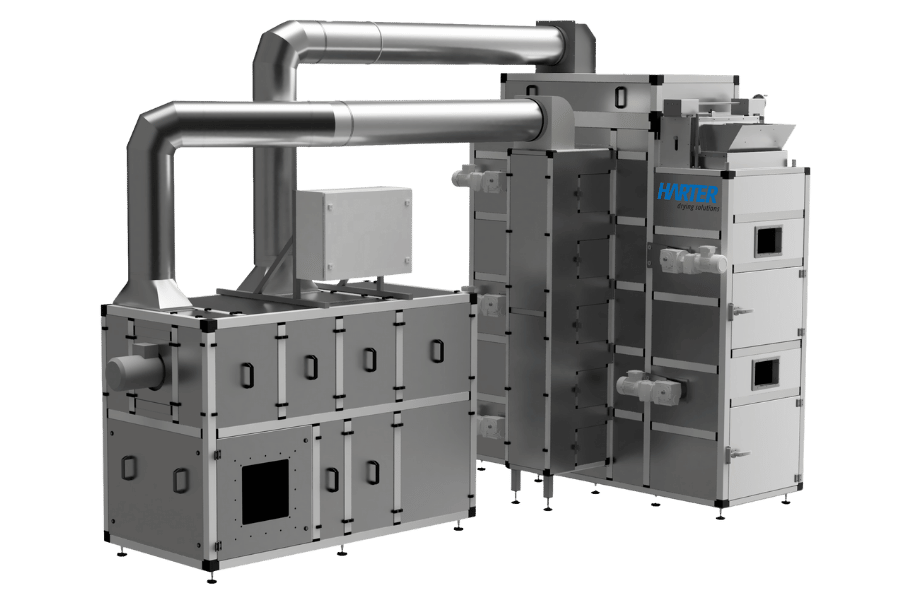

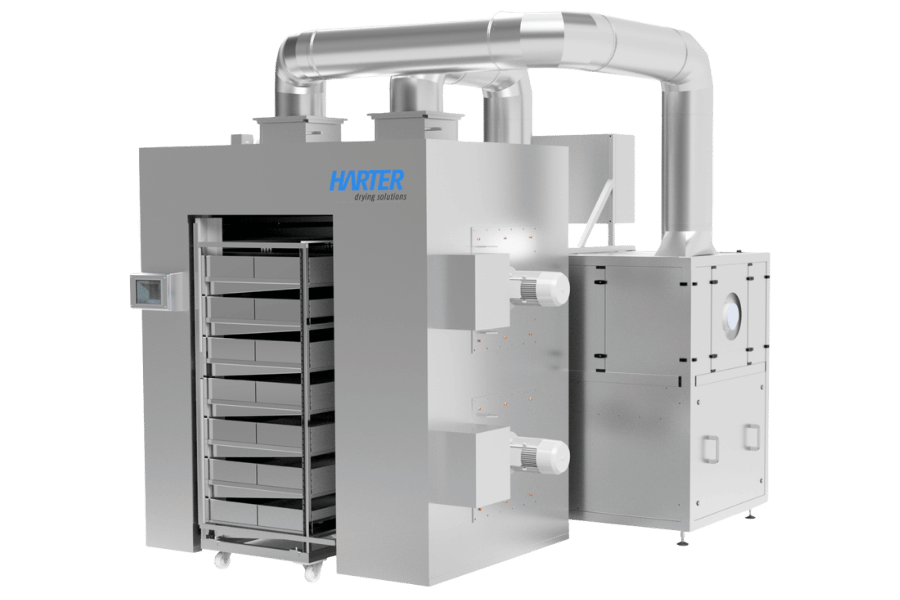

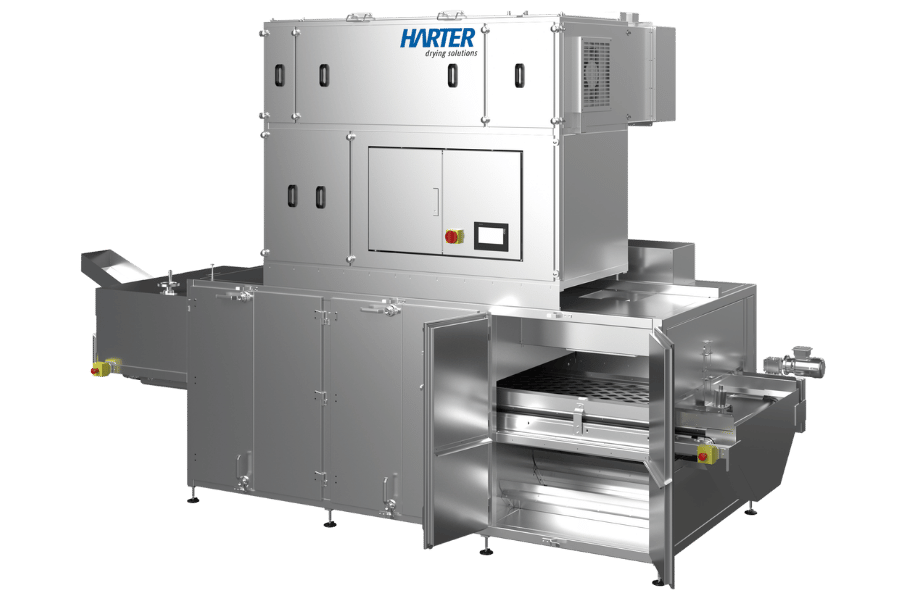

Depending on the product form (slices, pieces, cubes, whole fruits, herbs), production volume, and desired final moisture content, HARTER configures the suitable solution:

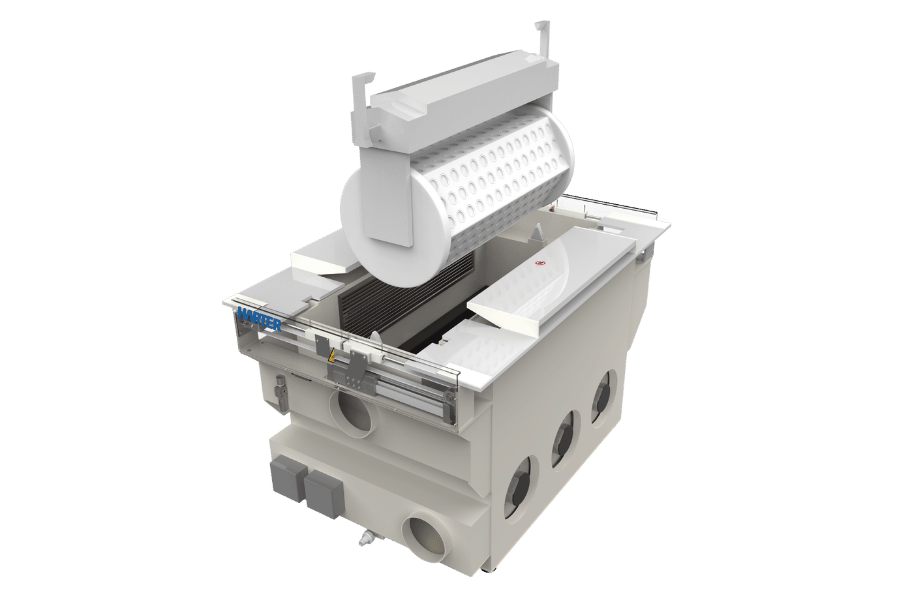

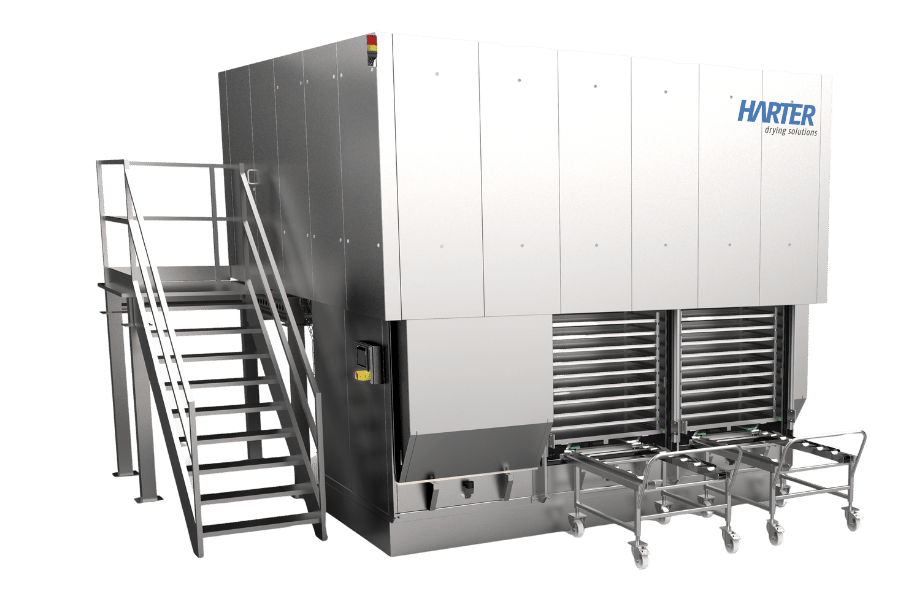

- Tray dryers/Chamber dryers for flexible batches (Food Tray Dryers/Chamber Dryers)

- Belt dryers for continuous throughput (Food Belt Dryers)

- Drum dryers for bulk products and snack formats (Food Drum Dryers)

The systems can be integrated into existing lines – from pre-treatment to packaging – including recipe management, moisture/temperature monitoring, and automatic data acquisition.

What our customers say

“Sometimes it is better to say nothing and let your customers speak for themselves.”

– Regina Mader, Managing Director

FAQ – Frequently Asked Questions about Drying Fruit & Vegetables

Fill out the form now and we will get in touch with you as soon as possible.

Brochures, technical reports, and press articles for those who want to know more details.