is special.

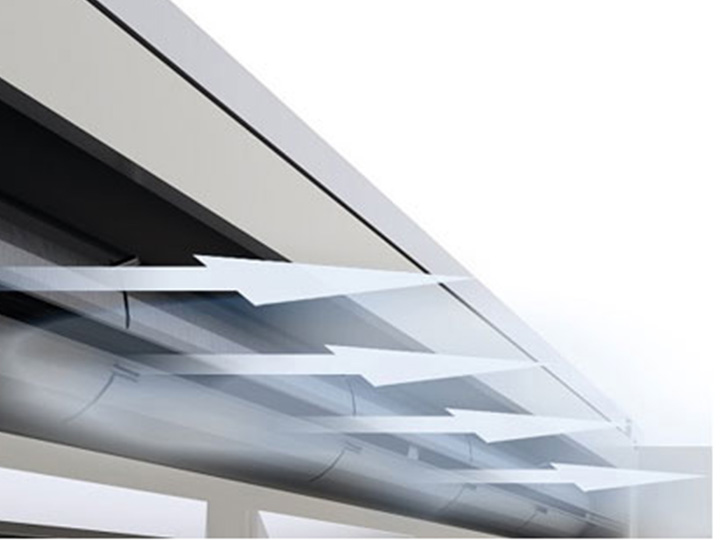

Non-compressed

Air Blowoff

Non-compressed signifies

_ Use of a powerful high-efficiency blower to provide large quantities of air

_ Air is applied evenly over the full length of the air knife rather than locally

_ Low energy input, compared with a compressor, resulting in much lower cost of operation

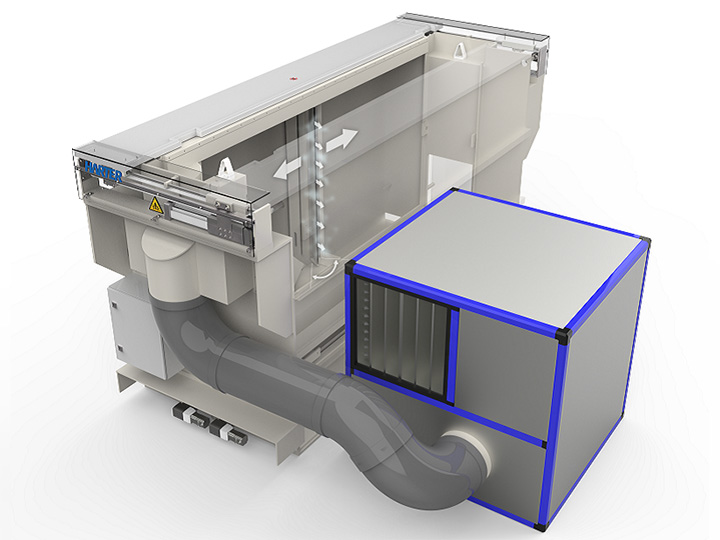

Separate Blowoff Station – For Components Liable to Water Entrapment

Separate blowoff station upstream of the dryer with a component dwell time not exceeding the cycle time

The blowoff station features movable air knives. The bulk of the water entrained is removed in the blowing-off process. The blowers of the station may be external or, alternatively, integrated type.

The movable air knives may be positioned horizontally or vertically as required by the components or the rack.

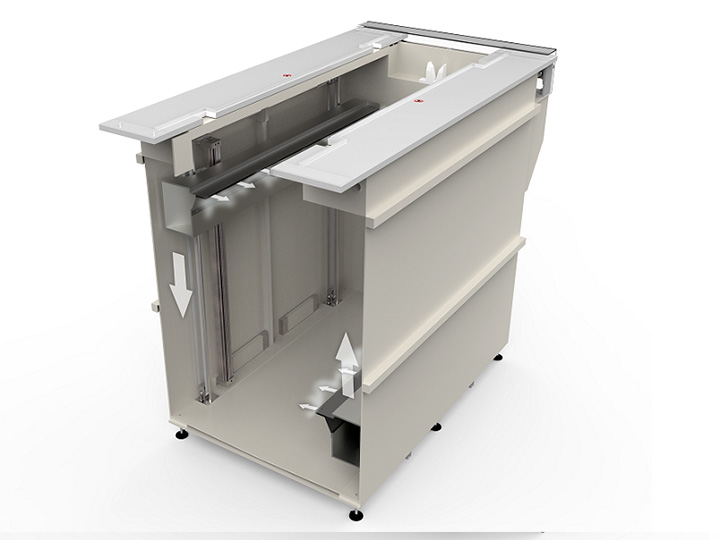

In-dryer Blowoff – for Components Liable to Water Entrapment

Stationary horizontal air knives integrated in the dryer below the lid

Once the rack is positioned above the dryer, the dryer lid opens and the blowoff system starts blowing. Upon entering the dryer the rack is subjected to the stream of air which removes the bulk of the water entrained. Once the rack has reached its bottom position the blowoff system stops blowing. The automatic lid system closes and the drying process proper commences.

The air knife angle of inclination may be shifted manually to ensure optimum water removal.