is special.

Efficient Drying of Wastewater Sludge -

a Good Solution in Many Respects

You may save up to 75 percent of your disposal cost if you do not only dewater but also subsequently dry your sludge. Drymex® dryers can ideally reduce the weight and volume of your sludge by 75 percent.

Many ways open up with dried sludge. It may conform with present or future regulations. Having a higher calorific value the dried sludge may be disposed of at a lower price. Heat pump assisted drying is extremely energy and carbon efficient. So, both your financial and environmental ambitions can be fulfilled.

Why heat pump assisted drying of all things? Compared with conventional systems a heat pump will save you an enormous amount of operating cost and carbon emission.

This may well be worth discussing, calculating, and considering. The potential of heat pump assisted drying will reveal itself in tests in our Test Center and with a loan dryer.

Details about wastewater sludge drying, how it works, and about our drying systems are given hereinunder.

Your Benefits

Saving money through drying

Most of the money spent on disposal is actually spent on water. Our heat pump assisted drying technique reduces the weight and volume of your sludge by as much as 75 percent. So, your disposal cost will consequently be 75 percent lower.

Low temperatures

Confidence through tests

Reducing energy consumption and carbon emission

Closed air circuit

The right air at the right place

Lasting value, robust and profitable

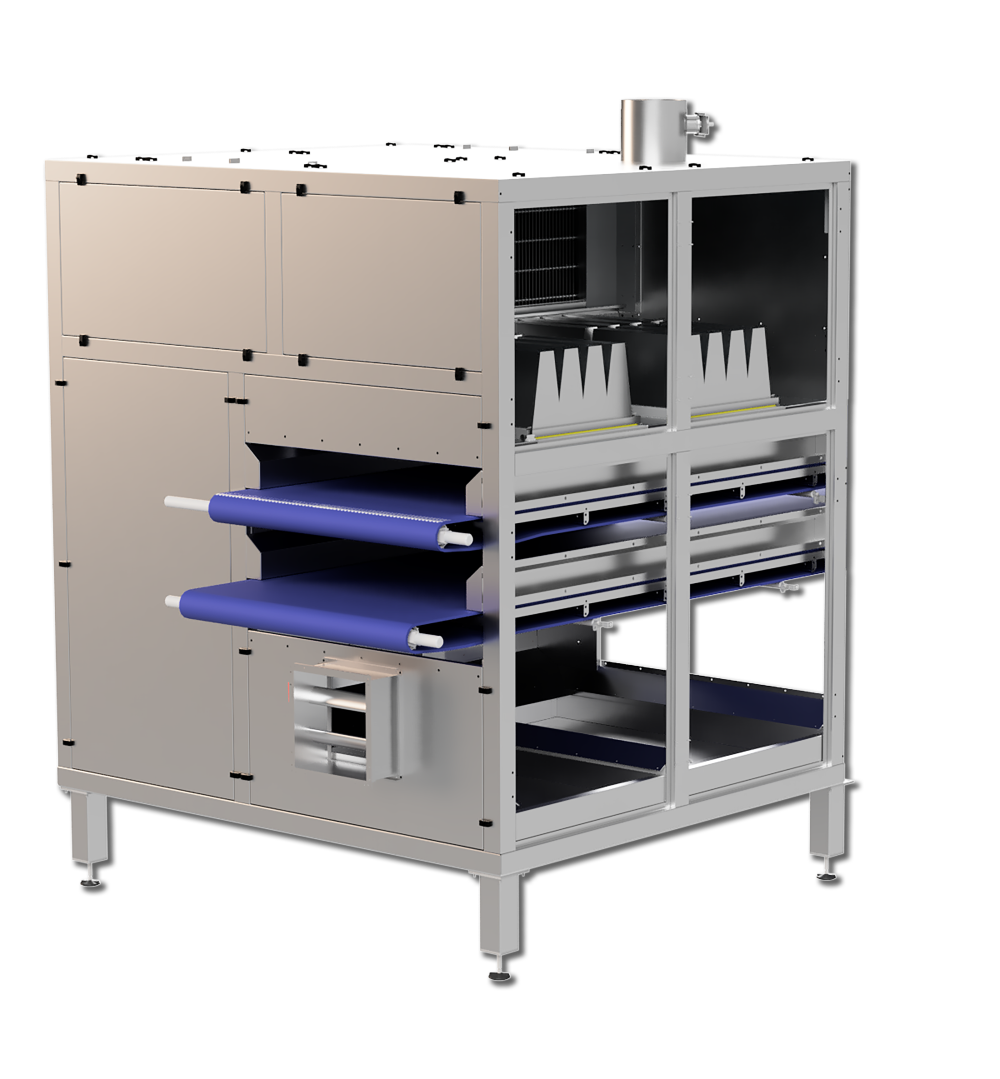

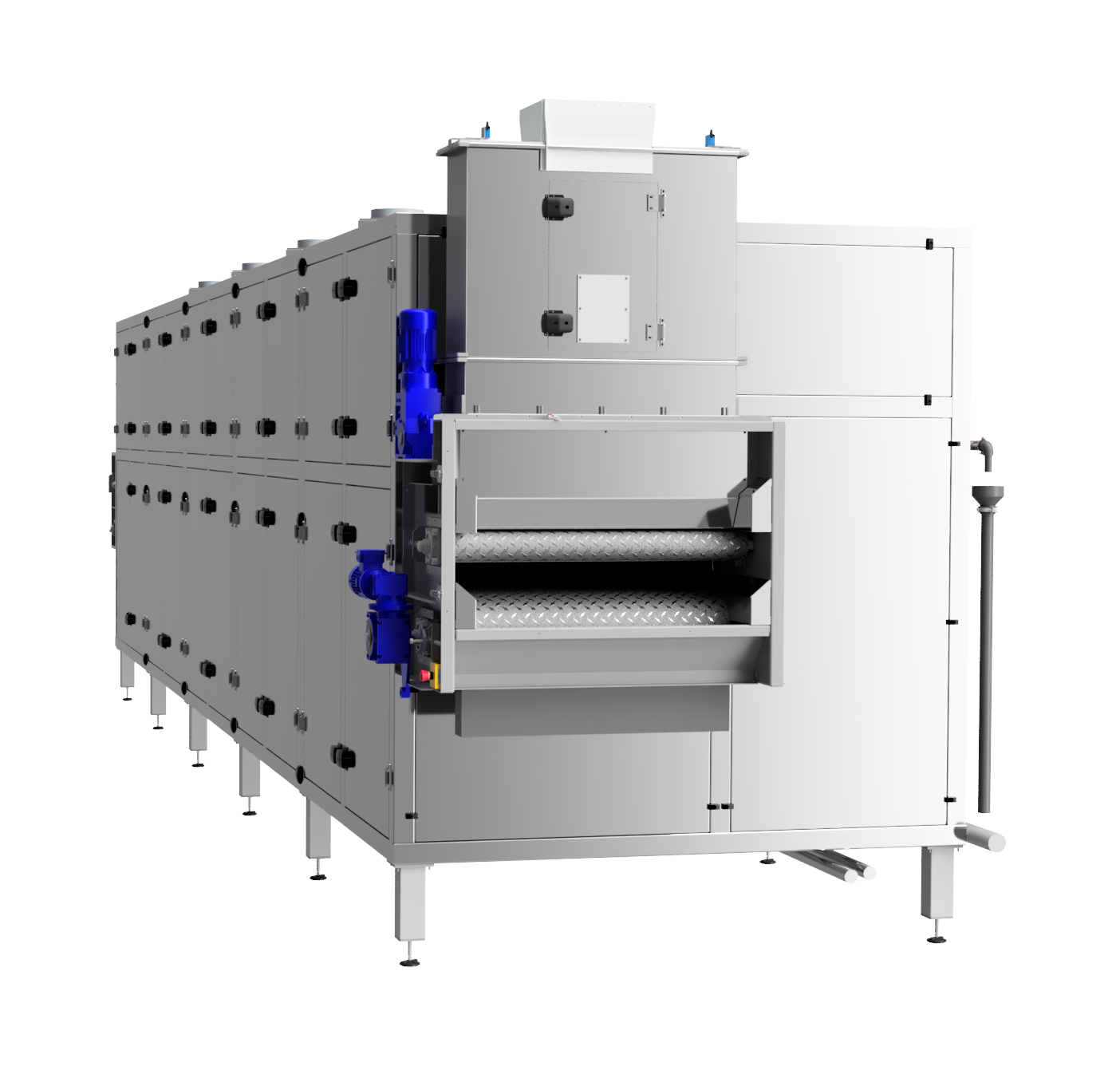

Belt dryer

for wastewater sludge drying

Our Drymex® drying systems can be used for pre-dewatered aqueous sludge and substrates. Continuous belt drying is the best solution for centrifugated or screw pressed wastewater sludge. Batch solutions may be offered if a chamber filter press is used.

Your application is different?

You will surely understand that we cannot possibly list all our potential applications.

If you have not found your application here, please do not hesitate to contact us. We will be glad to give you advice without engagement on your part!

Response to any demand

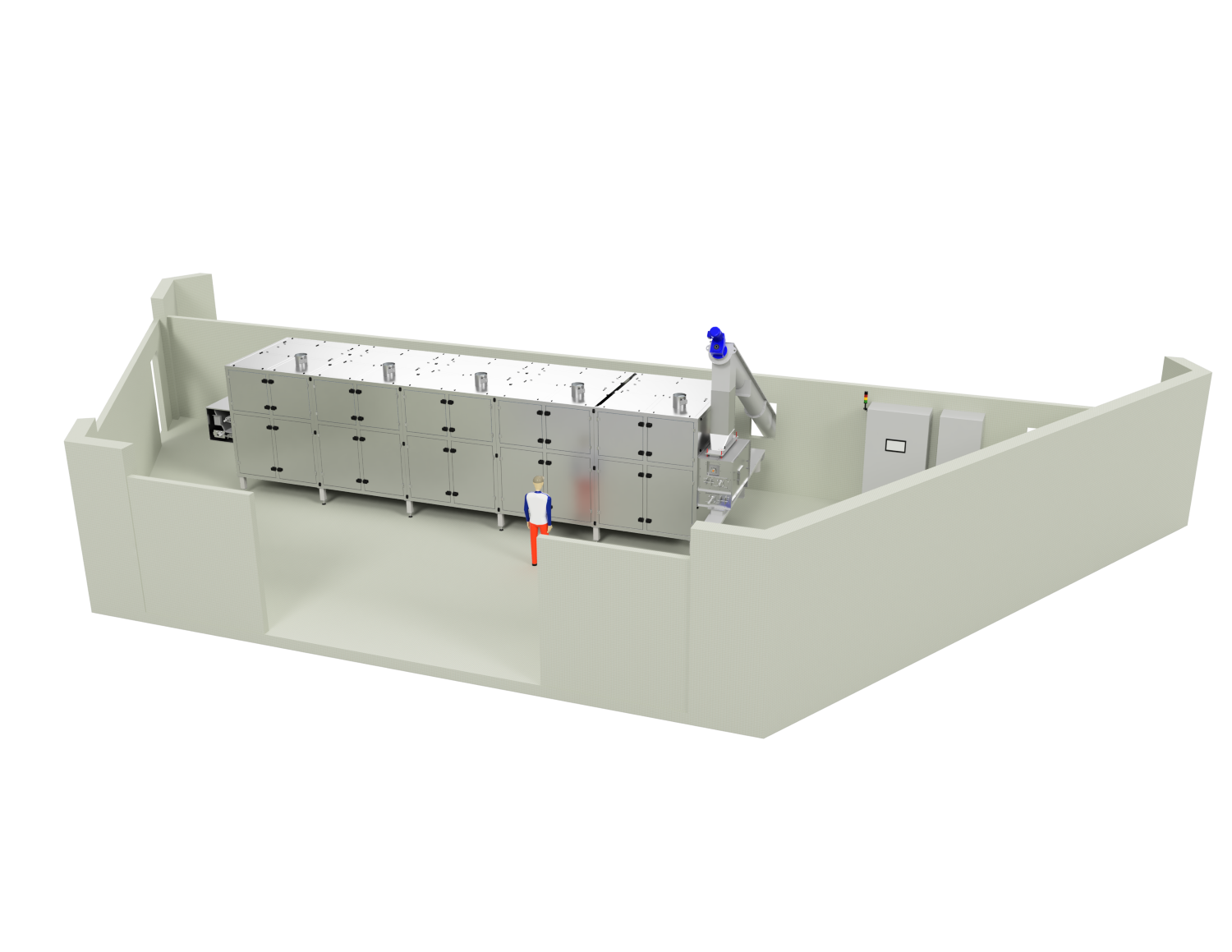

Our belt drying systems are modular solutions. We developed a special module which may have one or more of them added to give a system comprising ten modules maximum in line. So, you can have a drying system of the size required for your application.

Size

Each of our individual modules is capable of drying about 100 kg per hour of wastewater sludge. Modules may be added to dry 1,000 kg/h maximum. The present limit is 140,000 PE.

Conveyance

Our drying system requires sludge feeding in the hopper above the module, and removal of the sludge upon drying. Do you have a conveyance system that may be integrated with our drying system? Or do you need new conveyance? We may discuss the best solution for you.

The Process

The heat pump module provides the necessary process air and is also responsible for the condensation process: We use extremely dry and, thus, unsaturated air uniformly passed through the sludge. Efficient air conditioning combined with appropriate air routeing ensures quality drying results.

Click at the numbers inside the graphic to get further information.

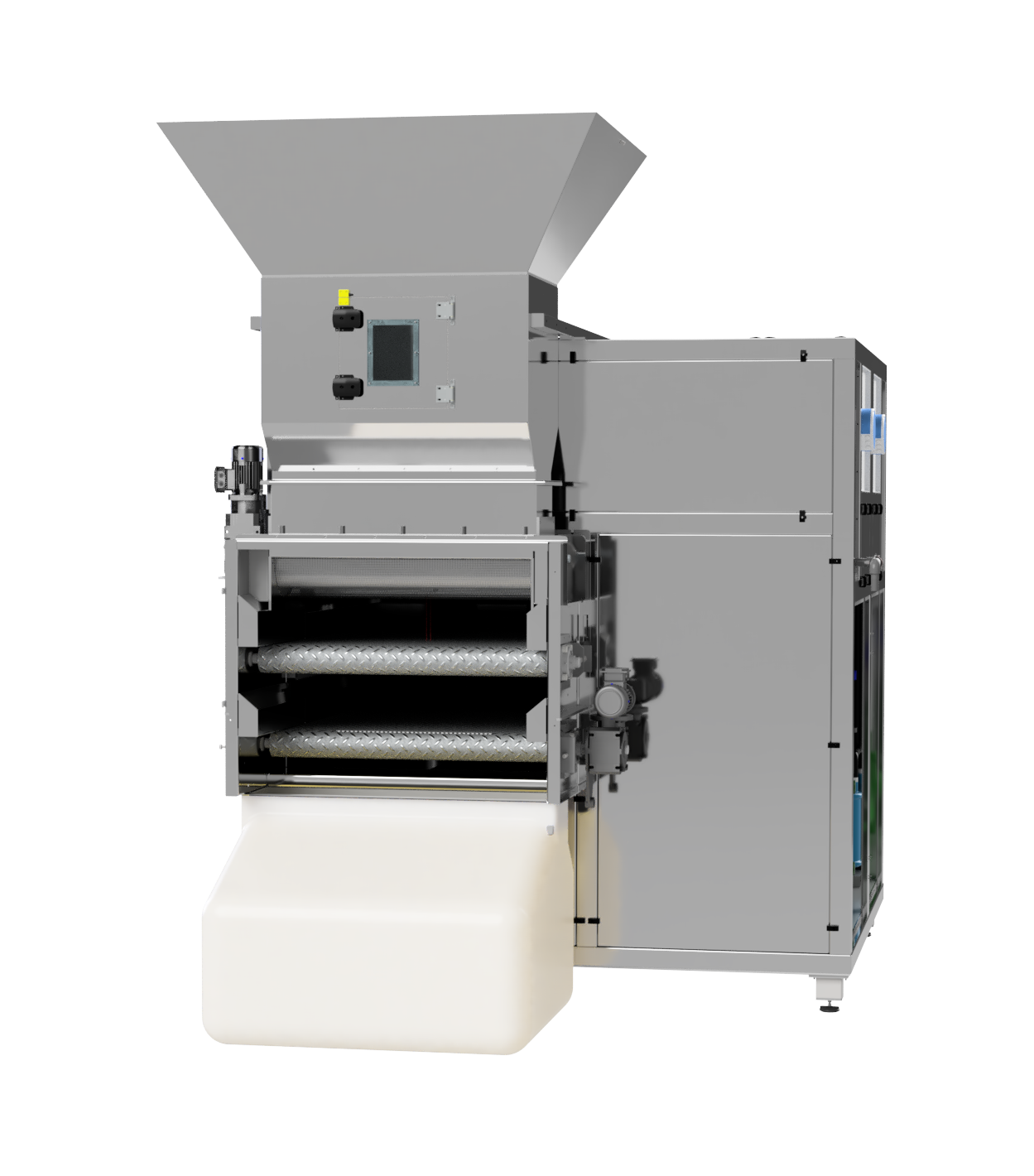

Test Center, Trials & Loan Dryers

Have your sludge tested

Drying tests in our test center are a reasonable approach to determine the parameters relevant for successful drying. We test your product for response to temperature, humidity, time, air speed and airflow rate. The test results form the basis for further layout and design, which will also reflect the knowhow gathered in hundreds of projects realised in various business sectors so far

Tell us the sludge quantity to be dried and send us a representative specimen. For a test in our Test Center, a two to three kg specimen will normally be sufficient. The drying test will show the potential weight and volume reduction. We will return the dried specimen upon completion of the test.

Tests on site

The test in our test center will provide an indication of the feasibility as such. If the outcome is positive, it appears reasonable to test larger sludge quantities, too. We offer our loan dryer for larger scale tests. The loan dryer is a belt dryer module for processing about 100 kg per hour. You may use this dryer to perform your own testing at your premises. It goes without saying that our engineer will give you a thorough instruction on using the dryer.

SALES

You are welcome to contact us without obligation.

+49 (0) 83 83 / 92 23 11 | info@harter-gmbh.de

AFTER SALES SERVICE

Our friendly staff will be happy to assist you.

Monday to Thursday from 8 a.m. to 12 p.m. and 1 p.m. to 4.30 p.m.

Friday from 8 a.m. to 2 p.m.

+49 (0) 83 83 / 92 23 20 | ass@harter-gmbh.de

BROCHURES & PRESS

- Harter 2024 Sewage Sludge Drying in Tyrol

- Harter 2022 Drying for more Sustainability

- Harter 2021 Low Carbon Emission Sludge drying

- Harter 2021 Dust-free Sludge drying

- Harter 2020 Secado de bajo consumo Harter (spanish)

- Harter 2019 Sludge Drying Reduces Cost – Efficient Drying Technology Chiresa

- Harter 2019 Custom Drying of Sewage Sludge Lanxess

- Harter 2019 drying sludge from electroplating

- Harter 2019 drying sludge from surface treatment Nicrola

- Harter 2019 Drying of Sludge from Flue Gas Cleaning

- Editorial Container Sludge Drying KVA Linth 2016

- Harter 2008 Sludge Drying Guilini