is special.

Fast and reliable Drying

of Packages

Following cleaning, pasteurization or sterilization, primary and secondary packages made from plastic, glass or metal, metal bands, plastic foils or thin superficial liquid films must be reliably dried for subsequent printing, labelling, final packaging or further processing.

The HARTER purpose developed Airgenex® condensation drying is capable of drying your packagings efficiently and swiftly no matter if the process is continuous or batch type.

Find information about our technology and its benefits for your product. Learn how our dryers work and how diverse their applications are.

Your Benefits

Very Fast

Efficient dehumidification combined with targeted air routing ensures extremely short drying times. The right air in the right place – this means for you: drying in a matter of seconds.

Very Reliable

Integrated heat pump technology and closed air circuit ensure highest efficiency of the drying process. Drying is independent of external climatic factors. The processes are reliable and reproducible.

Very Gentle

Your products are dried at temperatures variable between 20 °C and 90 °C. Drying at low temperatures saves both your packages and their contents.

Cooling Systems and Drying-Cooling Systems

With minor modification, our Airgenex® system may also be used for cooling if desired or required by the specific process. Owing to its physical approach heat pump based condensation drying is a process which may easily be used for both drying and cooling.

Air Blowing and Drying

In particularly challenging applications, we offer a non-compressed air blowing technology. It uses purpose developed blowing nozzles. Air blowing may be implemented as a preliminary stage to drying proper or as a separate blowing station.

Drying Systems

for Packages

We develop and manufacture drying systems both for batch and continuous operation adjusting our technology to your process and your product. We run preliminary drying tests in our test center to determine the specific parameters for successful drying.Our success is based on the perfect combination of two features – efficient air dehumidification and pinpoint air routeing.

Extremely dry and, thus, unsaturated air at low temperatures is routed exactly to the place where it is supposed to absorb humidity. This process – our heat pump based condensation drying – is implemented in various types of systems.

Products

With our energy-saving drying systems, you can gently dry almost all types of packaging.

Do you have a different product to the examples below? We are an innovative team and look forward to new tasks. Have your product tested in our pilot plant station without obligation. Contact us – we will be happy to advise you without obligation!

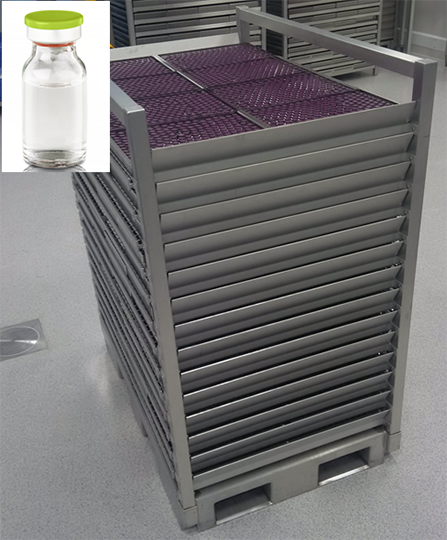

Bottles

Glass or plastic bottles, ampules or vials, unless fully dry externally, are rejected upon leakage and/or appearance testing. To prevent such false rejects the use of an efficient drying system should be considered. Our Airgenex® drying system increases productivity and improves product quality while ensuring highest process reliability.

Convenience Food

Are you among the up-and-coming convenience food manufacturers wanting to make it in the top flight of this soaring market? Then, efficient and reliable drying should be reflected in your idea or plan very early on. We know all about opening aid drying problems, excess humidity after pasteurization, excess temperature for further processing, and so on – all these challenges may be resolved using Airgenex® condensation drying.

Blister Packs

Airgenex® condensation drying is also recommendable for blister packs requiring drying after processes such us sterilization. The low temperatures used in this process ensure stress-free drying of both packages and product. It reconciles seemingly conflicting features such as short drying times and gentleness with the product.

Food Tins and Drink Cans

Many a fan, many a dryer cannot keep pace with the high speed of a production line. Tins or cans showing high external humidity and water droplets on their tabs are a stumbling block to smooth processing, an unacceptable situation for high output companies. Extremely dry air, targeted air routeing and, optionally, non-compressed air blowing – this combination ensures both fast and complete drying of your products.

Bags

After autoclaving, primary packagings such as infusion bags for the pharmaceutical industry or sauce bags for the food industry are humid and require proper drying. Cooling for subsequent processes is also required very often. Heat pump based condensation drying systems, when modified a little, may be used to do both jobs – for batch processes as well a continuous ones.

Stand-up Pouches

Complete drying of this packaging type for food or pet food is a big challenge – So, it is the right job for us! We offer a perfect combination of extremely dry air, targeted air routeing and non-compressed air blowing, if required, to provide solutions which will dry your products in a fast and reliable way.

Foil Wrappings

If foil wrappings, or their contents for that matter, require pasteurization to meet their intended purpose, they need to be dried, and probably also cooled, subsequently. Our heat pump based condensation drying can do both. It can, above all, dry the unseparated wrappings reliably, completely and gently so that they may be printed or subjected to further processing immediately.

The Process

You will get the best drying result possible because our design reflects a perfect combination of air conditioning and air routeing. Extremely dry air exactly directed on your products – and everything’s dry at wind speed!

Click at the numbers inside the graphic to get further information.

Where Drying becomes a Special Event

Our Test Center – where Ideas are forged

Our test center is unique.

A room full of technical equipment and opportunities.

A place full of creativity and innovation.

Tinkers with experience and inventive spirit.

Clients with faces in wonder

Please, come in!

Tests provide valuable Information and Confidence

Series of tests run in our test center provide valuable information and confidence. We test your product for response to temperature, time, humidity, air speed and airflow rate. We also look at the routeing of the air inside the dryer because this is a critical factor on the way to success. To do all this, we have several multifunctional dryers which our engineers adapt to the specific application. Our service to you includes, of course, an evaluation and interpretation of, and a comprehensive report on the results of these tests.

Sometimes, the parameters for a successful solution are clear at hand after just one series of tests. Every now and then, several runs with varying configurations are required. This is the moment when it takes the knowledge and creativity of our engineer to find a good solution. And we always find one.

We have run thousands of drying tests in our test center in more than 30 years. The experience gathered and the know-how obtained therefrom may not be valued high enough. And it is for your benefit.

A Day filled with more than just Engineering Matters

You are welcome to witness our tests. See with your very eyes how powerful our condensation drying is and how we create viable solutions. We will give you an insight into drying issues. It is equally important that your product and process expertise is duly reflected so that the joint project may be successful. We also cultivate hospitality and good company. So, your stay will be both pleasant and informative.

Loan Dryers & Special Services

It may appear reasonable to run drying tests at your premises using a system provided on loan. In such case, one of our qualified engineers will instruct you on how to run your own tests. We also build larger scale test set-ups as agreed.

You are a Manufacturer and want a better Dryer?

You already have a product and a process and wish to optimise your drying process? Maybe the energy consumption of your existing dryer is too high? Or you want to raise your throughput? A shorter drying time would be helpful? Or you just want to know the impact of our low temperatures on the ingredients, haptics and appearance of your product?

Our test center will provide answers to your questions. You tell us the ideal conditions under which your product should get dry. As an outcome of our tests, we will furnish a solution, which may be in accordance with hygienic design and GMP/GAMP requirements as required for the specific application. The results are very often much better than expected by our customers. We can routinely stun our customers in terms of time & temperature.

You have a new Product Idea?

You are planning to introduce an entirely new product and do not know exactly how to do the drying?

Whatever the challenge to be met we will be glad to deal with it. It is our passion to find the best drying solutions. When running tests, our engineer quickly sees which process is best suited to ensure successful drying. If products are particularly demanding there is always an engineering trick to help us arrive at a solution.

You are a Subcontract Processor of a wide Range of Products?

Let us suppose you are a subcontractor processing a wide range of products. You might not know yet which products you will process in the future. In such situations, our tests will reflect the most complex products to be dried. We will allow for some extra margin to give you maximum assurance. This way we can ultimately ensure that our system will be capable of covering your whole range of products today and later.

Our pilot plant station is a place where ideas are forged. People who can think creatively and alternatively work and tinker here. It is a place where challenging tasks turn into reliable solutions.

Reinhold Specht

SALES

You are welcome to contact us without obligation.

+49 (0) 83 83 / 92 23 11 | info@harter-gmbh.de

AFTER SALES SERVICE

Our friendly staff will be happy to assist you.

Monday to Thursday from 8 a.m. to 12 p.m. and 1 p.m. to 4.30 p.m.

Friday from 8 a.m. to 2 p.m.

+49 (0) 83 83 / 92 23 20 | ass@harter-gmbh.de